Abstract

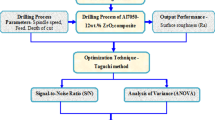

This paper presents the optimal conditions for the ultraviolet laser percussion drilling of alumina materials intended for use in heat sinks. The Taguchi method and grey relational analysis, along with the consideration of multiple quality characteristics, were applied for determining the optimal parameters. The entrance diameter and taper angle of the drilled hole were affected by the material processing parameters, including laser power, pulse duration, focal plane position, and number of pulses. The Taguchi method and grey relational analysis were used for assessing the effects of the operational parameters on multiple performance characteristics. Nine experiments based on an orthogonal array were performed. According to the results, the optimal process parameters were as follows: laser energy density, 3.82 J/cm2; focal plane position, 0.1 mm; number of pulses, 20 shots; and single pulse duration, 3 ms. Analysis of the grey relational grade revealed that the focal plane position was the most dominant parameter.

Similar content being viewed by others

References

Bharatish, A., Murthy, H.N.N., Anand, B., Madhusoodana, C.D., Praveena, G.S., Krishna, M.: Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt. Laser Technol. 53, 22–32 (2013)

Chang, C.L., Tsai, C.H., Chen, L.: Applying grey relational analysis to the decathlon evaluation model. Int. J. Comput. Internet Manag. 11, 54–63 (2003)

Chen, M.F., Ho, Y.S., Hsiao, W.T., Wu, T.H., Tseng, S.F., Huang, K.C.: Optimized laser cutting on light guide plates using grey relational analysis. Opt. Laser. Eng. 49, 222–228 (2011)

Chen, M.F., Hsiao, W.T., Wang, M.C., Yang, K.Y., Chen, Y.F.: A theoretical analysis and experimental verification of a laser drilling process for a ceramic substrate. Int. J. Adv. Manuf. Technol. 81, 1723–1732 (2015)

Chiang, K.T., Chang, F.P.: Optimization of the WEDM process of particle-reinforced material with multiple performance characteristics using grey relational analysis. J. Mater. Process. Technol. 180, 96–101 (2006)

Dubey, A.K., Yadava, V.: Multi-objective optimization of Nd:YAG laser cutting of nickel-based superalloy sheet using orthogonal array with principal component analysis. Opt. Laser. Eng. 46, 124–132 (2008)

Hanon, M.M., Akman, E., Oztoprak, B.G., Gunes, M., Taha, Z.A., Hajim, K.I., Kacar, E., Gundogdu, O., Demir, A.: Experimental and theoretical investigation of the drilling of alumina ceramic using Nd: YAG pulsed laser. Opt. Laser Technol. 44, 913–922 (2012)

Kao, J.Y., Tsao, C.C., Wang, S.S., Hsu, C.Y.: Optimization of the EDM parameters on machining Ti–6Al–4V with multiple quality characteristics. Int. J. Adv. Manuf. Technol. 47, 395–402 (2010)

Kopac, J., Krajnik, P.: Robust design of flank milling parameters based on grey-Taguchi method. J. Mater. Process. Technol. 191, 400–403 (2007)

Li, C.H., Tsai, M.J.: Multi-objective optimization of laser cutting for flash memory modules with special shapes using grey relational analysis. Opt. Laser Technol. 41, 634–642 (2009)

Pan, L.K., Wang, C.C., Wei, S.L., Sher, H.F.: Optimizing multiple quality characteristics via Taguchi method-based grey analysis. J. Mater. Process. Technol. 182, 107–116 (2007)

Rao, R., Yadava, V.: Multi-objective optimization of Nd: YAG laser cutting of thin superalloy sheet using grey relational analysis with entropy measurement. Opt. Laser Technol. 41, 922–930 (2009)

Ren, N., Jiang, L., Liu, D., Lv, L., Wang, Q.: Comparison of the simulation and experimental of hole characteristics during nanosecond-pulsed laser drilling of thin titanium sheets. Int. J. Adv. Manuf. Technol. 76, 735–743 (2015)

Samant, A.N., Dahotre, N.B.: Laser machining of structural ceramics—a review. J. Eur. Ceram. Soc. 29, 969–993 (2009)

Samant, A.N., Paital, S.R., Dahotre, N.B.: Process optimization in laser surface structuring of alumina. J. Mater. Process. Technol. 203, 498–504 (2008)

Tsai, M.J., Li, C.H.: The use of grey relational analysis to determine laser cutting parameters for QFN packages with multiple performance characteristics. Opt. Laser Technol. 41, 914–921 (2009)

Tan, X.R., Li, Y.G., Chen, M.Z.: Applications of gray relational analysis in gastroenterology. World J. Gastroenterol. 11, 3457–3460 (2005)

Venkatesan, K., Ramanujam, R., Kuppan, P.: Analysis of cutting forces and temperature in laser assisted machining of Inconel 718 using Taguchi method. Proc. Eng. 97, 1637–1646 (2014)

Wu, C.H.: On the application of Grey relational analysis and RIDIT analysis to Likert scale surveys. Int. Math. Forum 2, 675–687 (2007)

Zhao, W.Q., Wang, W.J., Jiang, G.D., Li, B.Q., Mei, X.S.: Ablation and morphological evolution of micro-holes in stainless steel with picosecond laser pulses. Int. J. Adv. Manuf. Technol. 80, 1713–1720 (2015)

Acknowledgements

The authors thank the Ministry of Science and Technology of Taiwan for financially supporting this research under Contract No. MOST 103-2221-E-018-004-MY2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, MF., Hsiao, WT., Wang, MC. et al. Multi-performance characterization analysis of diameter and taper angle on alumina ceramic via using pulsed ultraviolet laser percussion drilling method. Opt Quant Electron 49, 383 (2017). https://doi.org/10.1007/s11082-017-1222-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-017-1222-1