Abstract

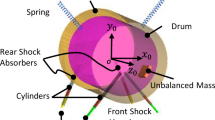

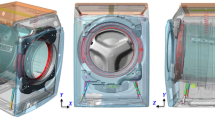

The vibrations originating from badly distributed load inside the drum are in this paper channeled into cost functions which are used as objectives for optimization. The defined kinematic cost function deals with performance of tub motion and can ensure margins to collision of parts inside the washing machine or constitute a step in the process to increase the machine capacity. The dynamic cost function measures transmitted vertical force to the hosting structure. Forces which cause noise and vibration impact on the surroundings. Two different cost functions for stability of a washing machine in the sense of walking avoidance are also presented. The difference between these formulations is studied with an example, which shows that although it is costly to evaluate the second formulation it will give more freedom to find good washing machine designs.

Three different applied problems which aim to optimize different suspension designs for new and existing washing machines are presented.

For effective numerical computation of the complex multiobjective optimization problems a multistep approach for washing machine structural optimization is presented. With the help of parallel calculation of the response of dynamic models implemented in Adams∖View, the approach has been used to solve the presented problems.

Results derived from the solution to the optimization problems have been used in development of new washing machines which afterwards have been put on the market.

Similar content being viewed by others

Notes

Due to a confidentiality agreement the exact figures are not made available here.

References

Berger EJ (2002) Friction modeling for dynamic system simulation. Appl Mech Rev 55(6):535–577

Berkof RS (1979) The input torque in linkages. Mech Mach Theory 14:61–73

Coello Coello CA, Van Veldhuizen DA, Lamont GB (2002) Evolutionary algorithms for solving multi-objective problems. Kluwer Academic, New York

Conrad DC (1994) The fundamentals of automatic washing machine design based upon dynamic constraints. Dissertation, Purdue University. ISBN 9780591345728

Conrad DC, Soedel W (1995) On the problem of oscillatory walk of automatic washing machines. J Sound Vib 188(3):301–314

Demeulenaere T, Berkof RS (2008) Improving machine drive dynamics: a structured design approach towards balancing. Trans ASME, J Mech Des 130:082302

Demeulenaere B, Swevers J, De Schutter J (2004) A convex optimization framework for dynamic balancing of planar linkages. In: Proceedings of the international conference on noise and vibration engineering, Leuven, Belgium, September 20–22, 2004

Equipment Energy Efficiency Committee (2010) Appliance energy consumption in Australia: equations for appliance star ratings. Retrieved from http://www.energyrating.gov.au/pubs/appliance-star-ratings.pdf. Accessed September 15, 2010

Mahmud A, Cuellar E (2010) Optimization of load distribution in washing machines using bio-inspired computational methods. Master’s Thesis no 2010:55, Chalmers University of Technology, ISSN:1652-8557

Merediz A (2009) Modeling of dehydration process in controlled spinning of washing machines. Master’s Thesis no 2009:33, Chalmers University of Technology, ISSN:1652-8557

Ngatchou P, Zarei A, El-Sharkawi MA (2005) Pareto multi objective optimization. In: Proceedings of the 13th international conference on intelligent systems application to power systems, Arlington, Virginia, USA, November 6–10

Nygårds T, Berbyuk V (2007) Dynamics of washing machines: MBS modeling and experimental validation. In: Proceedings of the multibody dynamics 2007, ECCOMAS thematic conference, Milano, Italy, June 25–28

Nygårds T, Berbyuk V (2008) Modeling and optimization of washing machine vibration dynamics. In: Proceedings of the 9th international conference on motion and vibration control (MOVIC 2008), Technische Universität München, Munich, Germany, September 15–18

Nygårds T, Berbyuk V (2010) Pareto optimization of a washing machine suspension system. In: Proceedings of the 2nd international conference on engineering optimization, Lisbon, Portugal, September 6–9

Nygårds T, Berbyuk V (2012) Multibody modeling and vibration dynamics analysis of washing machines. J Multibody Syst Dyn 27(2):197–238

Papadopoulos E, Papadimitriou I (2001) Modeling, design and control of a portable washing machine during the spinning cycle. In: Proceedings of the 2001 IEEE/ASME international conference on advanced intelligent mechatronics systems (AIM 2001), pp 899–904

Sobol IM, Statnikov RB (2006) Selecting optimal parameters multicriteria problems, 2nd edn. Drofa, Moscow (in Russian)

Sowards B (1972) Spring-damper suspension system analysis for horizontal-axis washing machines. Student Project Report, Department of Mechanical Engineering, University of Michigan, Ann Arbor, Michigan

Stadler W (1988) Multicriteria optimization in engineering & in the sciences. Plenum Press, New York

Statnikov R (1999) Multicriteria design: optimization and identification. Kluwer Academic, Dordrecht

Statnikov R, Matusov J (2001) Multicriteria analysis in engineering. Kluwer Academic, Dordrecht

Statnikov R, Statnikov A (2011) The parameter space investigation method toolkit. Artech House, Boston

Statnikov R, Matusov J, Statnikov A (2012) Multicriteria engineering optimization problems: statement, solution and applications. J Optim Theory Appl. doi:10.1007/s10957-012-0083-9

Türkay OS, Kiray B, Tugcu AK, Sümer IT (1995) Formulation and implementation of parametric optimisation of a washing machine suspension system. Mech Syst Signal Process 9(4):359–377

Türkay OS, Sümer IT, Tugcu AK, Kiray B (1998) Modeling and experimental assessment of suspension dynamics of a horizontal-axis washing machine. J Vib Acoust 120(2):534–543

Verschuure M, Demeulenaere B, Aertbeliën E, Swevers J, De Schutter J (2008a) Optimal counterweight balancing of spatial mechanisms using voxel-based discretizations. In: Proceedings of the international conference on noise and vibration engineering, Leuven, Belgium, September 15–17

Verschuure M, Demeulenaere B, Swevers J, De Schutter J (2008b) Counterweight balancing for vibration reduction of elastically mounted machine frame: a second-order cone programming approach. Trans ASME, J Mech Des 130:022302

Yuan Y (2008) Sensor fusion based testing station for unbalanced load estimation in horizontal washing machines. In: IEEE international instrumentation and measurement technology conference (I2MTC 2008), Victoria, Vancouver Island, Canada, May 12–15

Yörükoglu A, Altug E (2009) Determining the mass and angular position of the unbalanced load in horizontal washing machines. In: Proceedings of IEEE/ASME international conference on advanced intelligent mechatronics, Singapore, July 14–17

Zhang Z, Xie T, Garstecki GM, Xie MM, Slabbekoorn SD, Buendia AR (2010) Method and apparatus for monitoring load size and load imbalance in washing machine. United States Patent number 7739764. Published June 22

Acknowledgements

This work was supported financially by Asko Appliances AB, Vara, Sweden.

The authors wish to thank to Peder Bengtsson, Anders Eriksson, Patrik Jansson, Anders Sahlén and Marcus Person, all working at above mentioned company, for their support and ideas during the project within which this paper was written.

Author information

Authors and Affiliations

Corresponding author

Additional information

Commemorative Contribution.

Rights and permissions

About this article

Cite this article

Nygårds, T., Berbyuk, V. Optimization of washing machine kinematics, dynamics, and stability during spinning using a multistep approach. Optim Eng 15, 401–442 (2014). https://doi.org/10.1007/s11081-012-9206-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11081-012-9206-2