Abstract

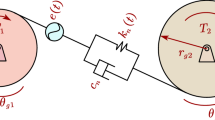

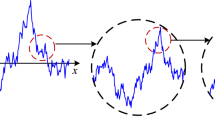

This paper aims to reveal the coupling relationship between surface topography and wear and introduce a new coupling failure dynamic model of tooth surface topography and wear. Based on the fractal theory, the theoretical model of gear rough surface and the prediction model of wear are established and reveal the relationship between tooth surface roughness, wear depth, and meshing position. In particular, we analyze rough tooth surfaces’ time-varying meshing stiffness and system dynamic characteristics. The greater the contact surface roughness level, the more severe the wear behavior, and the greater the contact deformation of the gear; the vibration response and amplitude growth rate are highly related to the surface roughness. The results of coupled vibration characteristics show that the topography of the contact surface causes the system noise and shock to increase from the two aspects of stiffness excitation and error excitation. The multi-state coupled dynamic model of the contact surface can provide a theoretical basis for optimizing gear systems.

Similar content being viewed by others

Data availability

The authors declare that the data supporting the 11 findings of this study are available within the article.

Abbreviations

- D :

-

Fractal dimension

- G :

-

The characteristic scale parameter

- L r :

-

The length scale of the asperity

- Ф :

-

The random phase

- ν :

-

Poisson’s ratio

- z :

-

Number of teeth

- m :

-

Module

- L :

-

Tooth width

- E :

-

Elastic modulus

- T :

-

The torque applied to the gearyhjhj

- N :

-

Meshing times

- k a :

-

Axial compression stiffness

- k b :

-

Bending stiffness

- k s :

-

Shear stiffness

- k h :

-

Hertzian stiffness

- k f :

-

Flexible base stiffness

- k re :

-

The stiffness of the elastic deformation

- k rep 1 :

-

The stiffness of the first elastic–plastic deformation

- k rep 2 :

-

The stiffness of the second elastic–plastic deformation

- k mesh :

-

Time-varying meshing stiffness under interdental coupling effects

- α 1 :

-

The base circle arc is half of the center angle of the circle

- α 2 :

-

The root arc of the tooth is half of the center angle of the circle

- α f :

-

The difference between the root circle pressure angle and α1 of the internal gear

- θ 0 :

-

The angle between the centerline of a tooth and the centerline of the adjacent tooth slot

- r b :

-

Base circle radius

- r f :

-

Root fillet radius

- h x :

-

Half the thickness of the teeth at the meshing point

- d :

-

The effective tooth length of integral

- V :

-

Wear volume

- S :

-

The relative sliding distance

- H :

-

Material hardness

- G w :

-

Viscosity coefficient

- G s :

-

The material shear deformation-related parameters

- P w :

-

The contact load changes with the meshing angle

- S w :

-

The tooth surface contact parameters

- R e :

-

The comprehensive radius of curvature

- a L :

-

The contact area of the largest asperity

- ψ :

-

The scale expansion coefficient

- K v :

-

Hardness coefficient

- h p :

-

Wear depth of contact point P

References

Sayles, R., Thomas, T.: Surface topography as a nonstationary random process. Nature 271(5644), 431–434 (1978). https://doi.org/10.1038/271431a0

Li, Z.X., Yan, X., Yuan, C., et al.: Virtual prototype and experimental research on gear multi-fault diagnosis using wavelet-autoregressive model and principal component analysis method. Mech. Syst. Signal Process. 25(7), 2589–2607 (2021). https://doi.org/10.1016/j.ymssp.2011.02.017

Liang, X., Zhang, H., Liu, L., et al.: The influence of teeth pitting on the mesh stiffness of a pair of external spur gears. Mech. Mach. Theory 106(1), 1–15 (2016). https://doi.org/10.1016/j.mechmachtheory.2016.08.005

Wu, B., Sun, Y.: Normal contact analysis between two self-affine fractal surfaces at the nanoscale by molecular dynamics simulations. Tribol. Lett. 71, 30 (2023). https://doi.org/10.1007/s11249-023-01705-8

Janakiraman, V., Li, S., Kahraman, A.: An investigation of the impacts of contact parameters on wear coefficient. J. Tribol. 136(3), 031602 (2014). https://doi.org/10.1115/1.4027440

Kogut, L., Etsion, I.: Elastic-plastic contact analysis of a sphere and a rigid flat. J. Appl. Mech. 69(5), 657–662 (2002). https://doi.org/10.1115/1.1490373

Amarnath, M., Chandramohan, S., Seetharaman, S., et al.: Experimental investigations of surface wear assessment of spur gear teeth. J. Vib. Control 18(7), 1009–1024 (2012). https://doi.org/10.1177/1077546311399947

Yu, G.B., Mao, H.H., Jiang, L.D., et al.: Fractal contact mechanics model for the rough surface of a beveloid gear with elliptical asperities. Appl. Sci. 12(8), 4071 (2022). https://doi.org/10.3390/app12084071

Chen, Z.G., Zhang, J., Zhai, W., et al.: Improved analytical methods for calculation of gear teeth fillet-foundation stiffness with teeth root crack. Eng. Fail. Anal. 82, 72–81 (2017). https://doi.org/10.1016/j.engfailanal.2017.08.028

Zhao, Z., Yang, Y., Han, H.Z., et al.: Meshing characteristics of spur gears considering three-dimensional fractal rough surface under elastohydrodynamic lubrication. Machines 10(8), 705 (2022). https://doi.org/10.3390/machines10080705

Liu, Z., Zhang, T., Zhao, Y., et al.: Time-varying stiffness model of spur gear considering the effect of surface morphology characteristics. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 233(2), 242–253 (2019). https://doi.org/10.1177/0954408918775955

Pan, W.J., Li, X.P., Wang, L.L., et al.: A normal contact stiffness fractal prediction model of dry-friction rough surface and experimental verification. Eur. J. Mech. A. Solids 66, 94–102 (2017). https://doi.org/10.1016/j.euromechsol.2017.06.010

Chen, H., Yin, Q., Dong, G., et al.: Stiffness model of fixed joint considering self- affinity and elastoplasticity of asperities. Ind. Lubr. Tribol. 72, 128–135 (2020). https://doi.org/10.1108/ILT-05-2019-0192

Guan, D., Jing, L., Gong, J., et al.: Normal contact analysis for spherical pump based on fractal theory. Tribol. Int. 124, 117–123 (2019). https://doi.org/10.1016/j.triboint.2018.04.002

Chen, Q., Xu, F., Liu, P., Fan, H.: Research on fractal model of normal contact stiffness between two spheroidal joint surfaces considering friction factor. Tribol. Int. 97, 253–264 (2016). https://doi.org/10.1016/j.triboint.2016.01.023

Yang, W., Li, H., Ma, D.Q., Yongqiao, W., Jian, C., et al.: Sliding friction contact stiffness model of involute arc cylindrical gear based on fractal theory. Int. J. Eng. 30, 109–119 (2017)

Xia, H., Meng, F.S., Zhang, X., et al.: Nonlinear dynamics analysis of gear system considering time-varying meshing stiffness and backlash with fractal characteristics. Nonlinear Dyn. 111, 14851–14877 (2023). https://doi.org/10.1007/s11071-023-08649-7

Gao, S., Han, Q., Zhou, N., et al.: Dynamic and wear characteristics of self-lubricating bearing cage: effects of cage pocket shape. Nonlinear Dyn. 110, 177–200 (2022). https://doi.org/10.1007/s11071-022-07611-3

Chang, W.R., Etsion, I., Bogy, D.B.: Static friction coeÿcient model for metallic rough surfaces. J. Tribol. 110(1), 57–63 (1988). https://doi.org/10.1115/1.3261575

Kim, J.Y., Baltazar, A., Rokhlin, S.I.: Ultrasonic assessment of rough surface contact between solids from elastoplastic loading–unloading hysteresis cycle. J. Mech. Phys. Solid. 52, 1911–1934 (2004). https://doi.org/10.1016/j.jmps.2004.01.006

Bajpai, P., Kahraman, A., Anderson, N.E.: A surface wear prediction methodology for parallel-axis gear pairs. J. Tribol. 126(3), 597–605 (2004). https://doi.org/10.1115/1.1691433

Morag, Y., Etsion, I.: Resolving the contradiction of asperities plastic to elasticmode transition in current contact models of fractal rough surfaces. Wear 262, 624–629 (2007). https://doi.org/10.1016/j.wear.2006.07.007

Wang, S., Komvopoulos, K.: A fractal theory of the interfacial temperature distribution in the slow sliding regime: part I—elastic contact and heat transfer analysis. J. Tribol. 116, 812–823 (1994). https://doi.org/10.1115/1.2927341

Brizmer, V., Kligerman, Y., Etsion, I.: Elastic–plastic spherical contact under combined normal and tangential loading in full stick. Tribol. Lett. 25(1), 61–70 (2007). https://doi.org/10.1007/s11249-006-9156-y

Liu, Y., Shangguan, B., Xu, Z.: A friction contact stiffness model of fractal geometry in forced response analysis of a shrouded blade. Nonlinear Dyn. 70, 2247–2257 (2012). https://doi.org/10.1007/s11071-012-0615-8

Liu, P., Zhao, H., Huang, K., et al.: Research on normal contact stiffness of rough surface considering friction based on fractal theory. Appl. Surf. Sci. 349, 43–48 (2015). https://doi.org/10.1016/j.apsusc.2015.04.174

Zhai, C., Gan, Y.X., Proust, G., et al.: The role of surface structure in normal contact stiffness. Exp. Mach. 56, 359–368 (2016). https://doi.org/10.1007/s11340-015-0107-0

Yousfi, B.E., Soualhi, A., Medjaher, K., et al.: Electromechanical modeling of a motor–gearbox system for local gear tooth faults detection. Mech. Syst. Signal Process. 166, 108435 (2022). https://doi.org/10.1016/j.ymssp.2021.108435

Huang, K., Cheng, Z.B., Xiong, Y.S., et al.: Bifurcation and chaos analysis of a spur gear pair system with fractal gear backlash. Chaos Solitons Fractals 142, 110387 (2021). https://doi.org/10.1016/j.chaos.2020.110387

Kumar, M., Bharti, R.K., Das, M.: Study of surface finishing mechanism in arotational-magnetorheological miniature gear profile polishing using novel flow restrictor. Wear 488–489, 204120 (2022). https://doi.org/10.1016/j.wear.2021.204120

Wang, S.Y., Zhu, R.P.: An improved mesh stiffness model for double-helical gear pair with spalling defects considering time-varying friction coefficient under mixed EHL. Eng. Fail. Anal. 121, 105174 (2021). https://doi.org/10.1016/j.engfailanal.2020.105174

Wei, D., Zhai, C., Hanaor, D.A., et al.: Contact behaviour of simulated rough spheres generated with spherical harmonics. Int. J. Solids Struct. 193–194, 54–68 (2020). https://doi.org/10.1016/j.ijsolstr.2020.02.009

Sainsot, P., Velex, P., Duverger, O.: Contribution of gear body to tooth deflections - a new bidimensional analytical formula. J. Mech. Des. 126, 748–752 (2004). https://doi.org/10.1115/1.1758252

Zhou, W., Tang, J., He, Y., et al.: Modeling of rough surfaces with given roughness parameters. J. Central South Univ. 24, 127–136 (2017). https://doi.org/10.1007/S11771-017-3415-Y

Zhao, B., Zhang, S., Wang, P., et al.: Loading–unloading normal stiffness model for power-law hardening surfaces considering actual surface topography. Tribol. Int. 90, 332–342 (2015). https://doi.org/10.1016/j.triboint.2015.04.045

Liao, J.P., Zhang, J.F., Feng, P.F., et al.: Identification of contact stiffness of shrink-fit tool-holder joint based on fractal theory. Int. J. Adv. Manuf. Technol. 90, 2173–2184 (2017). https://doi.org/10.1007/s00170-016-9506-3

Wang, D., Wang, R., Wang, B., et al.: Effect of vibration on emergency braking tribological behaviors of brake shoe of deep coal mine hoist. Appl. Sci. 11, 6441 (2021). https://doi.org/10.3390/app11146441

Thanh, C.L., Khuong, D.N., Minh, H.L., et al.: Nonlocal strain gradient IGA numerical solution for static bending, free vibration and buckling of sigmoid FG sandwich nanoplate. Physica B 631, 413726 (2022). https://doi.org/10.1016/j.physb.2022.413726

Tran, V.T., Nguyen, T.K., Hung, X.N., et al.: Vibration and buckling optimization of functionally graded porous microplates using BCMO-ANN algorithm. The-Walled Structures. 182, 110267 (2022). https://doi.org/10.1016/j.tws.2022.110267

Dai, H., Long, X.H., Chen, F., et al.: An improved analytical model for gear mesh stiffness calculation. Mech. Mach. Theory 159, 104262 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104262

Ma, H., Song, R.Z., Pang, X., et al.: Time-varying mesh stiffness calculation of cracked spur gears. Eng. Fail. Anal. 44, 179–194 (2014). https://doi.org/10.1016/j.engfailanal.2014.05.018

Xie, C.Y., Hua, L., Lan, J., et al.: Improved analytical models for mesh stiffness and load sharing ratio of spur gears considering structure coupling effect. Mech. Syst. Signal Process. 111, 331–347 (2018). https://doi.org/10.1016/j.ymssp.2018.03.037

Xie, C.Y., Hua, L., Han, X.H., et al.: Analytical formulas for gear body-induced teeth deflections of spur gears considering structure coupling effect. Int. J. Mech. Sci. 148, 174–190 (2018). https://doi.org/10.1016/j.ijmecsci.2018.08.022

Chen, Z.G., Zhou, Z.W., Zhai, W.M., et al.: Improved analytical calculation model of spur gear mesh excitations with teeth profile deviations. Mech. Mach. Theory 149, 103838 (2022). https://doi.org/10.1016/j.mechmachtheory.2020.103838

Shen, Z.X., Qiao, B.J., Yang, L.H., et al.: Evaluating the influence of teeth surface wear on TVMS of planetary gear set. Mech. Mach. Theory 136, 206–223 (2019). https://doi.org/10.1016/j.mechmachtheory.2019.03.014

Wang, H.B., Zhou, C.J., Wang, H.H., et al.: A novel contact model for rough surfaces using piecewise linear interpolation and its application in gear wear. Wear 476, 203685 (2021). https://doi.org/10.1016/j.wear.2021.203685

Yu, X., Sun, Y.Y., Zhao, D., et al.: A revised contact stiffness model of rough curved surfaces based on the length scale. Tribol. Int. 164, 107206 (2021). https://doi.org/10.1016/j.triboint.2021.107206

Xiao, H.F., Sun, Y.Y.: On the normal contact stiffness and contact resonance frequency of rough surface contact based on asperity micro-contact statistical models. Eur. J. Mech. A. Solids 75, 450–460 (2019). https://doi.org/10.1016/j.euromechsol.2019.03.004

Yang, L., Wang, L., Yu, W., et al.: Investigation of tooth crack opening state on time varying meshing stiffness and dynamic response of spur gear pair. Eng. Fail. Anal. 121, 1–13 (2021). https://doi.org/10.1016/j.engfailanal.2020.105181

Raghuwanshi, N.K., Parey, A.: Experimental measurement of gear mesh stiffness of cracked spur gear by strain gauge technique. Measurement 86, 266–275 (2016). https://doi.org/10.1016/j.measurement.2016.03.001

Mo, S., Luo, B.R., Song, W.H., et al.: Geometry design and teeth contact analysis of non-orthogonal asymmetric helical face gear drives. Mech. Mach. Theory 173, 104831 (2022). https://doi.org/10.1016/j.mechmachtheory.2022.104831

Mo, S., Zhang, Y.X., Song, Y.L., et al.: Nonlinear vibration and primary resonance analysis of non-orthogonal face gear-rotor-bearing system. Nonlinear Dyn. 108, 3367–3389 (2022). https://doi.org/10.1007/s11071-022-07432-4

Mo, S., Wang, L., Liu, M., et al.: Study of the time-varying mesh stiffness of two-stage planetary gear train considering tooth surface wear. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. (2023). https://doi.org/10.1177/09544062231170633

Mo, S., Zhang, T., Jin, G.G., et al.: Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear. Mech. Mach. Theory 144, 103670 (2022). https://doi.org/10.1016/j.mechmachtheory.2019.103670

Mo, S., Li, Y.H., Wang, D.D., et al.: An analytical method for the meshing characteristics of asymmetric helical gears with tooth modifications. Mech. Mach. Theory 185, 105321 (2023). https://doi.org/10.1016/j.mechmachtheory.2023.105321

Mo, S., Li, Y.H., Lou, B.R., et al.: Research on the meshing characteristics of asymmetric gears considering the tooth profile deviation. Mech. Mach. Theory 175, 104926 (2022). https://doi.org/10.1016/j.mechmachtheory.2022.104926

Litak, G., Friswell, M.I.: Dynamics of a gear system with faults in meshing stiffness. Nonlinear Dyn. 41, 415–421 (2005). https://doi.org/10.1007/s11071-005-1398-y

Chen, Z., Ning, J., Wang, K., et al.: An improved dynamic model of spur gear transmission considering coupling effect between gear neighboring teeth. Nonlinear Dyn. 106, 339–357 (2021). https://doi.org/10.1007/s11071-021-06852-y

Zhang, Y., Zhu, L.Y., Gou, X.F.: Calculation methods of load distribution ratio for spiral bevel gear. Int. J. Mech. Sci. 257C, 108531 (2023). https://doi.org/10.1016/j.ijmecsci.2023.108531

Mu, X., Sun, W., Liu, C., Yuan, B., et al.: Numerical simulation and accuracy verification of surface morphology of metal materials based on fractal theory. Materials 13, 4158 (2022). https://doi.org/10.3390/ma13184158

Yu, X., Sun, Y.Y., Liu, S., et al.: Fractal-based dynamic response of a pair of spur gears considering microscopic surface morphology. Int. J. Mech. Syst. Dyn. 1(2), 194–206 (2021). https://doi.org/10.1002/msd2.12004

Acknowledgements

This research is financially supported by National Natural Science Foundation of China (No. 52265004), National Key Laboratory of Science and Technology on Helicopter Transmission (No. HTL-0-21G07), Guangxi Science and Technology Major Program (No. 2023AA19005), Open Fund of State Key Laboratory of Digital Manufacturing Equipment and Technology, Huazhong University of Science and Technology (No. DMETKF2021017), Interdisciplinary Scientific Research Foundation of Guang Xi University (No. 2022JCC022), and Entrepreneurship and Innovation Talent Program of Taizhou City, Jiangsu Province (No. 20212333).

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Shuai Mo and Lei Wang contributed equally to this manuscript, Shuai Mo and Lei Wang are co-first authors of the article. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mo, S., Wang, L., Hu, Q. et al. Coupling failure dynamics of tooth surface morphology and wear based on fractal theory. Nonlinear Dyn 112, 175–195 (2024). https://doi.org/10.1007/s11071-023-09038-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-09038-w