Abstract

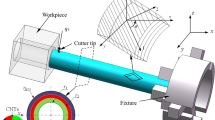

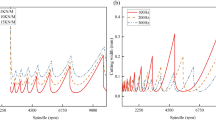

Compared with traditional linear models, the nonlinear model of boring can profoundly reveal the physical mechanism and mathematical laws of chatter occurrence, and has more rich scientific connotations. The nonlinear kinematic equations of the composite boring system containing carbon nanomaterials (CNMs) are derived by utilizing the energy method, which is taken to be the entry point for this paper. First of all, the basic mechanical parameters for the composite boring bar CNMs-embedded are derived based on the Halpin–Tsai Model (HTM) and the Rules of Mixture (ROM). From the perspective of continuous distribution, the mathematical expressions of kinetic and potential energy of the rotating boring bar are proposed by introducing the nonlinear strain. The specific and detailed nonlinear dynamic equations of the boring system are obtained using the extended Hamilton’s principle by considering the non-conservative virtual work consists of the nonlinear regenerative cutting and the damping force resulting from the viscoelastic and hysteretic damping of composite. Next, the nonlinear equations above are numerically decomposed and simplified using the general Galerkin method combined with modal expansion. The compact nonlinear equations are solved by the Multi-scale method and the primary and super-harmonic resonance solutions are obtained for the forward and backward modes, respectively. Then, the above nonlinear theoretical models are validated with published literature. Finally, the effects of CNMs, carbon fibers, cutting technological parameters on chatter amplitude as well as the unstable zone (curves) are investigated. The conclusions obtained confirm that the nonlinear theoretical model of the boring system proposed in present paper can effectively predict the complex relationships between various parameters within the boring system and provide theoretical guidance for the design of the composite cutter bar.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Munoa, J., Beudaert, X., Dombovari, Z., Altintas, Y., Budak, E., Brecher, C., Stépán, G.: Chatter suppression techniques in the metal cutting. CIRP Ann. Manuf. Technol. 65(2), 785–808 (2016). https://doi.org/10.1016/j.cirp.2016.06.004

Zhu, L.D., Liu, C.F.: Recent progress of chatter prediction, detection and suppression in milling. Mech. Syst. Signal. Pr. 143(9), 106840-1–37 (2020). https://doi.org/10.1016/j.ymssp.2020.106840

Wang, W.K., Wan, M., Zhang, W.H., Yang, Y.: Chatter detection methods in the machining processes: a review. J. Manuf. Process. 77(5), 240–259 (2022). https://doi.org/10.1016/j.jmapro.2022.03.018

Lee, D.G., Suh, N.P.: Manufacturing and testing of chatter free boring bars. CIRP Ann. Manuf. Technol. 37(1), 365–368 (1988). https://doi.org/10.1016/S0007-8506(07)61655-2

Lee, D.G., Hwang, H.Y., Kim, J.K.: Design and manufacture of a carbon fiber epoxy rotating boring bar. Compos. Struct. 60(1), 115–124 (2003). https://doi.org/10.1016/S0263-8223(02)00287-8

Ghorbani, S., Rogov, V.A., Carluccio, A., Belov, P.S.: The effect of composite boring bars on vibration in machining process. Int. J. Adv. Manuf. Tech. 105, 1157–1174 (2019). https://doi.org/10.1007/s00170-019-04298-6

Thorenz, B., Friedrich, M., Westermann, H.H., Döpper, F.: Evaluation of the influence of different inner cores on the dynamic behavior of boring bars. Proc. CIRP 81, 1171–1176 (2019). https://doi.org/10.1016/j.procir.2019.03.287

Waydande, S., Mahajan, D.A., Gajjal, S.Y.: A review on vibration attenuation of boring bar using passive dampers. Int. J. Emerg. Technol. Adv. Eng. 4(4), 117–122 (2014). https://doi.org/10.15623/ijret.2015.0407020

Nagano, S., Koizumi, T., Fujii, T., Tsujiuchi, N., Ueda, H., Steel, K.: Development of a composite boring bar. Compos. Struct. 38(1–4), 531–539 (1997). https://doi.org/10.1016/s0263-8223(97)00089-5

Song, Q.H., Shi, J.H., Liu, Z.Q., Wan, Y., Xia, F.: Boring bar with constrained layer damper for improving process stability. Int. J. Adv. Manuf. Technol. 83(9–12), 1951–1966 (2016). https://doi.org/10.1007/s00170-015-7670-5

Liu, Y., Liu, Z.Q., Song, Q.H., Wang, B.: Development of constrained layer damping tool-holder to improve chatter stability in end milling. Int. J. Mech. Sci. 117(10), 299–308 (2016). https://doi.org/10.1016/j.ijmecsci.2016.09.003

Zhang, Y.H., Ren, Y.S., Tian, J.S., Ma, J.M.: Chatter stability of the constrained layer damping composite boring bar in cutting process. J. Vib. Control 25(16), 2204–2214 (2019). https://doi.org/10.1177/1077546319852240

Zhang, J.F., Wang, H., Ren, Y.S., Feng, C., Zhang, C.J.: Chatter and stability analysis of the slender composite boring bar with constrained damping Layer. Appl. Sci. 10(13), 1–19 (2020). https://doi.org/10.3390/app10134537

Yuvaraju, B.A.G., Nanda, B.K., Srinivas, J.: Investigation of stability in internal turning using a boring bar with a passive constrained layer damping. FME Trans. 49(2), 384–394 (2021). https://doi.org/10.5937/fme2102384Y

Wang, J., Wu, F.H., Han, Y.L., Sun, D.X.: Boring bar design with laminar composite structure and research on properties. Chin. Mech. Eng. 24(6), 711–715 (2013). https://doi.org/10.3969/j.issn.1004-132X.2013.06

Wang, J., Wang, J.C., Wu, F.H., Zhou, Y., Bai, H.: Research of visco-elastic damping anti-vibration grinding wheel spindle with composite structure. J. Mech. Eng. 50(15), 192–197 (2014). https://doi.org/10.3901/JME.2014.15.192

Ma, J.M., Ren, Y.S.: Free vibration and chatter stability of a rotating thin-walled composite bar. Adv. Mech. Eng. 10(9), 1–10 (2018). https://doi.org/10.1177/1687814018798265

Ma, J.M., Xu, J.F., Ren, Y.S.: Analysis on free vibration and stability of rotating composite milling bar with large aspect ratio. Appl. Sci. 10(10), 3557-1–17 (2020). https://doi.org/10.3390/app10103557

Ma, J.M., Xu, J.F., Li, L.F., Liu, X.G., Gao, M.: Analysis of cutting stability of a composite variable-section boring bar with a large length-to-diameter ratio considering internal damping. Mater. 15(15), 5465-1–22 (2022). https://doi.org/10.3390/ma15155465

Kim, W., Argento, A., Scott, R.A.: Forced vibration and dynamic stability of a rotating tapered composite timoshenko shaft: Bending motions in end-milling operations. J. Sound Vib. 246(4), 583–600 (2001). https://doi.org/10.1006/jsvi.2000.3521

Ren, Y.S., Zhang, Y.H.: Investigation of chatter stability of cutting process with a rotating tapered cutter bar considering internal and external damping. Int. J. Adv. Manuf. Tech. 107(3–4), 1755–1771 (2020). https://doi.org/10.1007/s00170-020-05049-8

Ren, Y.S., Zhang, Y.H., Zhang, J.F.: Analytical instability of milling with rotating tapered composite tool considering internal damping. Eng. Mech. (Online). https://doi.org/10.6052/j.issn.1000-4750.2022.02.0197

Zhang, Y.H., Ren, Y.S., Zhang, J.F.: Stability analysis of cutting process with internally damped rotating tapered composite cutter bar. Math. Probl. Eng. 2020, 1–23 (2020). https://doi.org/10.1155/2020/2587820

Zorzi, E.S., Nelson, H.D.: Finite element simulation of rotor bearing systems with internal damping. Trans. ASME J. Eng. Power 99, 71–76 (1977). https://doi.org/10.1115/1.3446254

Arumugam, A.B., Rajamohan, V., Bandaru, N., Edwin, S.P., Kumbhar, S.G.: Vibration analysis of a carbon nanotube reinforced uniform and tapered composite beams. Arch. Acoust. 44(2), 309–320 (2019). https://doi.org/10.24425/aoa.2019.128494

DeValve, C., Pitchumani, R.: Analysis of vibration damping in a rotating composite beam with embedded carbon nanotubes. Compos. Struct. 110(4), 289–296 (2014). https://doi.org/10.1016/j.compstruct.2013.12.007

Thomas, B., Roy, T.: Vibration and damping analysis of functionally graded carbon nanotubes reinforced hybrid composite shell structures. J. Vib. Control 23(11), 1711–1738 (2015). https://doi.org/10.1177/1077546315599680

Heydarpour, Y., Malekzadeh, P.: Dynamic stability of rotating FG-CNTRC cylindrical shells under combined static and periodic axial loads. Int. J. Struct. Stab. Dyn. 18(12), 1850151-1–29 (2018). https://doi.org/10.1142/s0219455418501511

Ansari, R., Torabi, J., Shakouri, A.H.: Vibration analysis of functionally graded carbon nanotube-reinforced composite elliptical plates using a numerical strategy. Aerosp. Sci. Technol. 60(1), 152–161 (2017). https://doi.org/10.1016/j.ast.2016.11.004

Alawy, A., Abdlghany, M., Zakaria Wafy, T., Hassan, A.: Effect of functionalized multi-wall carbon nanotubes/Biresin CR82 epoxy nanocomposite on vibration attenuation of aluminum plate. J. Vib. Control 27(15–16), 1910–1919 (2021). https://doi.org/10.1177/1077546320950518

Udatha, P., Sekhar, A.S., Velmurugan, R.: The effect of CNT to enhance the dynamic properties of hybrid composite tube shafts. Mech. Adv. Mater. Struct. 26(1), 88–92 (2019). https://doi.org/10.1080/15376494.2018.1534172

Hong, M.K., Choi, W.K., Park, J.H., Kuk, Y.S., Kim, B.S., Seo, M.K.: Relationship between functionalized MWCNT and damping properties of MWCNT/CFRP composites for shaft. J. Nanosci. Nanotechnol. 20(11), 6862–6870 (2020). https://doi.org/10.1166/jnn.2020.18810

Zhang, J.F., Tong, Z.F., Ren, Y.S., Feng, C., Cao, X.L., Zhong, P.S.: Dynamical stability analysis of rotating composite cutter bar with nanocarbon materials. Int. J. Struct. Stab. Dyn. 23(9), 2350102-1–30 (2023). https://doi.org/10.1142/S021945542350102X

Fu, Q.L., Lundin, D., Nicolescu, C.M.: Anti-vibration engineering in internal turning using a carbon nanocomposite damping coating produced by PECVD process. J. Mater. Eng. Perform. 23(2), 506–517 (2014). https://doi.org/10.1007/s11665-013-0781-y

Yuvaraju, B.A.G., Nanda, B.K., Srinivas, J.: Optimal cutting state predictions in internal turning operation with nano-SiC/GFRE composite layered boring tools. Int. J. Mach. Mach. Mater. 23(1), 1–20 (2021). https://doi.org/10.1504/IJMMM.2021.112714

Hanna, N.H., Tobias, S.A.: A theory of nonlinear regenerative chatter. J. Eng. Ind. 96(1), 247–255 (1974). https://doi.org/10.1115/1.3438305

Vela-Martínez, L., Jáuregui-Correa, C., González-Brambila, O.M., Herrera-Ruiz, G., Lozano-Guzmán, A.: Instability conditions due to structural nonlinearities in regenerative chatter. Nonlinear Dyn. 56(4), 415–427 (2009). https://doi.org/10.1007/s11071-008-9411-x

Deshpande, N., Fofana, M.S.: Nonlinear regenerative chatter in turning. Robot. Cim-Int. Manuf. 17(1–2), 107–112 (2001). https://doi.org/10.1016/s0736-5845(00)00043-0

Stépán, G., Insperger, T., Szalai, R.: Delay, parametric excitation, and the nonlinear dynamics of cutting processes. Int. J. Bifurcat. Chaos 15(9), 2783–2798 (2005). https://doi.org/10.1142/S0218127405013642

Moradi, H., Movahhedy, M.R., Vossoughi, G.: Bifurcation analysis of milling process with tool wear and process damping: regenerative chatter with primary resonance. Nonlinear Dyn. 70(1), 481–509 (2012). https://doi.org/10.1007/s11071-012-0470-7

Moradi, H., Vossoughi, G., Movahhedy, M.R., Ahmadian, M.T.: Forced vibration analysis of the milling process with structural nonlinearity, internal resonance, tool wear and process damping effects. Int. J. Non-Linear Mech. 54, 22–34 (2013). https://doi.org/10.1016/j.ijnonlinmec.2013.02.005

Jung, J., Ngo, C., Son, D., Seok, J.: Nonlinear modeling and dynamic simulation using bifurcation and stability analyses of regenerative chatter of ball-end milling process. Math. Probl. Eng. 2016, 4368680-1–16 (2016). https://doi.org/10.1155/2016/4368680

Jalili, M.M., Hesabi, J., Abootorabi, M.M.: Simulation of forced vibration in milling process considering gyroscopic moment and rotary inertia. Int. J. Adv. Manuf. Technol. 89(9–12), 2821–2836 (2017). https://doi.org/10.1007/s00170-016-9618-9

Mokhtari, A., Jalili, M.M., Mazidi, A.: Study on frequency response and bifurcation analyses under primary resonance conditions of micro-milling operations. Appl. Math. Model. 87, 404–429 (2020). https://doi.org/10.1016/j.apm.2020.06.016

Ma, B.L., Ren, Y.S.: Nonlinear dynamic analysis of the cutting process of a non-extensible composite boring bar. Shock. Vib. 2020(8), 5971540-1–13 (2020). https://doi.org/10.1155/2020/5971540

Yao, D.H., Ren, Y.S., Zhang, Y.H., Ma, B.L.: Nonlinear dynamics of cutting process considering higher-order deformation of composite cutting tool. Shock. Vib. 2021, 8699218-1–23 (2021). https://doi.org/10.1155/2021/8699218

Ren, Y.S., Yao, D.H.: Forced vibration in cutting process considering the nonlinear curvature and inertia of a rotating composite cutter bar. Math. Probl. Eng. 2020, 2463136-1–19 (2020). https://doi.org/10.1155/2020/2463136

Arab, S.B., Rodrigues, J.D., Bouaziz, S., Haddar, M.: Stability analysis of internally damped rotating composite shafts using a finite element formulation. CR Mecan 346(4), 291–307 (2018). https://doi.org/10.1016/j.crme.2018.01.002

Halpin, J.C.: Stiffiness and expansion estimates for oriental short fiber composites. J. Compos. Mater. 3(4), 732–734 (1969). https://doi.org/10.1177/002199836900300419

Melanson, J., Zu, J.W.: Free vibration and stability analysis of internally damped rotating shafts with general boundary conditions. J. Vib. Acoust. 120(3), 776–783 (1998). https://doi.org/10.1115/1.2893897

Rafiee, M.A., Rafiee, J., Wang, Z., Song, H.H., Yu, Z.Z., Koratkar, N.: Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 3(12), 3884–3890 (2009). https://doi.org/10.1021/nn9010472

Ubaid, A.M., Dweiri, F.T., Ojiako, U.: Organizational excellence methodologies (OEMs): a systematic literature review. Int. J. Syst. Assur. Eng. Manag. 11(6), 1395–1432 (2020). https://doi.org/10.1007/s13198-020-01017-3

Gupta, V., Rathi, N.: Various objects detection using Bayesian theory. In: Proceedings of the International Conference on Computer Applications-Computer Applications-II. Research Publishing Services (2010). https://doi.org/10.3850/978-981-08-7304-2-1476

Arcos-Medina, G., Mauricio, D.: Aspects of software quality applied to the process of agile software development: a systematic literature review. Int. J. Syst. Assur. Eng. Manag. 10(5), 867–897 (2019). https://doi.org/10.1007/s13198-019-00840-7

Zhang, Z.P., Wang, Z.L.: Design of financial big data audit model based on artificial neural network. Int. J. Syst. Assur. Eng. Manag. (2021) (online). https://doi.org/10.1007/s13198-021-01258-w

Li, C.-W., Chao, Y.-Y.: The effect of auditing assurance levels on accounting conservatism: evidence from Taiwan. Int. J. Syst. Assur. Eng. Manag. 11(1), 64–76 (2020). https://doi.org/10.1007/s13198-019-00925-3

Alrae, R., Nasir, Q., Talib, M.A.: Developing house of information quality framework for IoT systems. Int. J. Syst. Assur. Eng. Manag. 11(6), 1294–1313 (2020). https://doi.org/10.1007/s13198-020-00989-6

Gupta, V., Mittal, M., Mittal, V.: FrWT-PPCA-based r-peak detection for improved management of healthcare system. IETE J. Res. (2021). (online). https://doi.org/10.1080/03772063.2021.1982412

Gupta, V., Mittal, M., Mittal, V.: A novel FrWT based arrhythmia detection in ECG signal using YWARA and PCA. Wirel. Pers. Commun. 124(2), 1229–1246 (2022). https://doi.org/10.1007/s11277-021-09403-1

Gupta, V., Saxena, N.K., Kanungo, A., Kumar, P., Diwania, S.: PCA as an effective tool for the detection of r-peaks in an ECG signal processing. Int. J. Syst. Assur. Eng. Manag. 13(5), 2391–2403 (2022). https://doi.org/10.1007/s13198-022-01650-0

Gupta, V., Mittal, M., Mittal, V., Chaturvedi, Y.: Detection of r-peaks using fractional Fourier transform and principal component analysis. J. Ambient Intell. Hum. Comput. 13(2), 961–972 (2022). https://doi.org/10.1007/s12652-021-03484-3

Gupta, V., Mittal, M., Mittal, V., Saxena, N.K., Chaturvedi, Y.: Nonlinear technique-based ECG signal analysis for improved healthcare systems. In: Algorithms for Intelligent Systems, pp. 247–255. Springer, Singapore (2021). https://doi.org/10.1007/978-981-16-3246-4_20

Gupta, V., Mittal, M., Mittal, V.: A simplistic and novel technique for ECG signal pre-processing. IETE J. Res. (2022). https://doi.org/10.1080/03772063.2022.2135622

Gupta, V.: Application of chaos theory for arrhythmia detection in pathological databases. Int. J. Med. Eng. Inform. 15(2), 191 (2023). https://doi.org/10.1504/IJMEI.2023.129353

Gupta, V., Mittal, M., Mittal, V., Saxena, N.K.: Spectrogram as an emerging tool in ECG signal processing. In: Recent Advances in Manufacturing, Automation, Design and Energy Technologies, pp. 407–414. Springer, Singapore (2021). https://doi.org/10.1007/978-981-16-4222-7_47

Gupta, V., Mittal, M., Mittal, V., Diwania, S., Saxena, N.K.: ECG signal analysis based on the spectrogram and spider monkey optimisation technique. J. Inst. Eng. (India) Ser. B 104(1), 153–164 (2023). https://doi.org/10.1007/s40031-022-00831-6

Gupta, V., Mittal, M., Mittal, V., Gupta, A.: An efficient AR modelling-based electrocardiogram signal analysis for health informatics. Int. J. Med. Eng. Inform. 14(1), 74–89 (2022). https://doi.org/10.1504/IJMEI.2022.119314

Gupta, V.: Wavelet transform and vector machines as emerging tools for computational medicine. J. Ambient Intell. Hum. Comput. 14(4), 4595–4605 (2023). https://doi.org/10.1007/s12652-023-04582-0

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 11672166) and the Natural Science Foundation of Shandong Province (Grant no. ZR202103070107).

Funding

The funding was provided by the National Natural Science Foundation of China (Grant No. 11672166) and the Natural Science Foundation of Shandong Province (Grant No. ZR202103070107).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Jia, J., Feng, C. et al. Investigation of chatter suppression by using rotating composite boring bar CNT-filled based on a modified nonlinear dynamical model. Nonlinear Dyn 111, 20735–20770 (2023). https://doi.org/10.1007/s11071-023-08986-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08986-7