Abstract

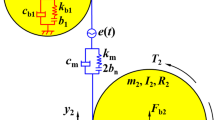

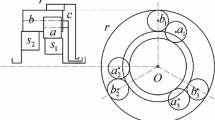

The mesh phasing angle is an important influencing factor in a gear dynamic system. However, previous studies of mesh phasing in a multi-stage gear system ignore the coupling effects of coaxial teeth ratio. Therefore, this paper derives the coupling relationship between mesh phasing angle and coaxial teeth ratio in a multi-stage gear system. The dynamic model for a two-stage parallel shaft gear train with time-varying mesh stiffness is established. The phase relationship is validated by rigid-flexible coupling model. Through the derived coupling relationship, it is found that the coaxial teeth ratio reduces the periodic variation range of mesh phasing. When the coaxial teeth ratio is not equal to 1, the effect of mesh phasing on the nonlinear vibration response of the system is investigated, and the suppression effect on the system vibration is found. The influence of mesh phasing on the chaotic motion of the system is analyzed in detail. The effect of mesh phasing on the vibration characteristics is compared for different coaxial teeth ratio. Finally, the change law of system vibration is revealed under the interaction of coaxial teeth ratio and mesh phasing, which provides a reference for the dynamic design of a multi-stage gear system.

Similar content being viewed by others

Data availability

The data can be made available on reasonable request.

Abbreviations

- \(J_{i} \left( {i = 1,2,3,4} \right)\) :

-

Inertia of the i gear

- \(z_{i} \left( {i = {1},{2},{3},{4}} \right)\) :

-

Teeth number of the i gear

- \({\text{To}}_{i} \left( {i = {1},{2}} \right)\) :

-

Input and output torque

- \(k_{i} (t)\left( {i = {1},{2}} \right)\) :

-

Time-varying mesh stiffness of the i stage

- \(k_{12} (t),k_{12}^{\prime } (t)\) :

-

The coupling stiffness of the first and second stages

- \(k_{{i{\text{m}}}} \left( {i = {1},{2}} \right)\) :

-

Mean value of the time-varying mesh stiffness of the i stage

- \(k_{h} ,k_{{\text{f}}}\) :

-

Contact stiffness, fillet-foundation stiffness

- \(k_{{\text{b}}} ,k_{{\text{s}}} ,k_{{\text{a}}}\) :

-

Bending stiffness, shear stiffness and axial compressive stiffness

- \(k_{e}\) :

-

Mesh stiffness

- \(c_{i} \left( {i = {1},{2}} \right)\) :

-

Mesh damping of the i stage

- \(b_{i} \left( {i = {1},{2}} \right)\) :

-

Nonlinear backlash of the i stage

- \(u_{i} \left( {i = 1,2} \right)\) :

-

Dynamic transmission error of the i stage

- \(q_{i} \left( {i = 1,2} \right)\) :

-

Dimensionless dynamic transmission error of the i stage

- \(\tau\) :

-

Dimensionless time

- \(b_{n}\) :

-

System characteristic length

- \(\omega_{n}\) :

-

System characteristic frequency

- \(\omega_{ij} \left( {i = 1,2;j = 1,2} \right)\) :

-

Dimensionless characteristic frequency

- \(F_{i} \left( {i = 1,2} \right)\) :

-

Dimensionless input and output load force

- \(e_{i} \left( {i = 1,2} \right)\) :

-

Dimensionless static transmission error of the i stage

- \(\alpha\) :

-

Pressure angle

- \(\beta\) :

-

Operating pressure angle

- \(\theta_{f}\) :

-

Angle between the tooth center-line and the junction with the root circle

- \(u_{fi} \left( {i = 1,2} \right)\) :

-

Distance along the tooth centerline measured from the tooth root to the loading tooth section

- \(S_{f}\) :

-

Tooth root thickness

- \(r_{f}\) :

-

Root circle radius

- \(r_{in}\) :

-

Hub bore radius

- \(E,\upsilon\) :

-

Material Young’s modulus and Poisson's ratio

- \(L\) :

-

Tooth width

- \(G\) :

-

Shear modulus

- \(I_{y1} ,I_{y2}\) :

-

Moment of inertia of the cross-sectional area \(y_{1} ,y_{2}\)

- \(A_{y1} ,A_{y2}\) :

-

Cross-sectional area \(y_{1} ,y_{2}\)

- \(\begin{gathered} L_{i}^{*} ,M_{i}^{*} ,P_{i}^{*} \;{\text{and}}\;Q_{i}^{*} \hfill \\ R_{j}^{*} ,S_{j}^{*} ,T_{j}^{*} ,U_{j}^{*} \;{\text{and}}\;V_{j}^{*} \hfill \\ \end{gathered}\) (i = 1,2,3; j = 2,3):

-

Coefficients expressing the fillet-foundation deformation a based on \(r_{f}\), \(r_{in}\) and \(\theta_{f}\)

- \(\varepsilon\) :

-

Contact ratio

- \(k_{i}^{(0)} (t)\left( {i = 1,2} \right)\) :

-

Average mesh stiffness of the first and second stages

- \(k_{i}^{(s)} (t)\left( {i = 1,2} \right)\) :

-

Mesh stiffness of the s Fourier coefficient

- \(\varphi_{is} \left( {i = 1,2} \right)\) :

-

The s mesh phasing

- \(\Omega_{i} \left( {i = 1,2} \right)\) :

-

Mesh frequency of the first and second stages

- \(T_{1} ,T_{2} ,T_{12}\) :

-

Mesh period of the first stage, the second stage and the total

- \(\Phi_{1} ,\Phi_{2} ,\Phi_{12}\) :

-

Characteristic quantity of the relationship between the coaxial teeth ratio and the mesh phasing of a two-stage gear system

- \(F_{{{\text{m}}1}} ,F_{{{\text{m}}2}}\) :

-

Mesh force of first stage and second stage

References

Zhang, A., Wei, J., Shi, L., Qin, D., Lim, T.C.: Modeling and dynamic response of parallel shaft gear transmission in non-inertial system. Nonlinear Dyn. 98, 997–1017 (2019). https://doi.org/10.1007/s11071-019-05241-w

Kahraman, A.: Dynamic analysis of a multi-mesh helical gear train. Proc. ASME Des. Eng. Tech. Conf. Part F1680, 365–373 (1992). https://doi.org/10.1115/DETC1992-0046

Lin, J., Parker, R.G.: Mesh stiffness variation instabilities in two-stage gear systems. J. Vib. Acoust. Trans. ASME. 124, 68–76 (2002). https://doi.org/10.1115/1.1424889

Parker, R.G.: Physical explanation for the effectiveness of planet phasing to suppress planetary gear vibration. J. Sound Vib. 236, 561–573 (2000). https://doi.org/10.1006/jsvi.1999.2859

Parker, R.G., Lin, J.: Mesh phasing relationships in planetary and epicyclic gears. J. Mech. Des. Trans. ASME. 126, 365–370 (2004). https://doi.org/10.1115/1.1667892

Al-Shyyab, A., Kahraman, A.: Non-linear dynamic analysis of a multi-mesh gear train using multi-term harmonic balance method: period-one motions. J. Sound Vib. 284, 151–172 (2005). https://doi.org/10.1016/j.jsv.2004.06.010

Al-Shyyab, A., Kahraman, A.: Non-linear dynamic analysis of a multi-mesh gear train using multi-term harmonic balance method: sub-harmonic motions. J. Sound Vib. 279, 417–451 (2005). https://doi.org/10.1016/j.jsv.2003.11.029

Gill-Jeong, C.: Numerical study on reducing the vibration of spur gear pairs with phasing. J. Sound Vib. 329, 3915–3927 (2010). https://doi.org/10.1016/j.jsv.2010.04.005

Guo, Y., Parker, R.G.: Analytical determination of mesh phase relations in general compound planetary gears. Mech. Mach. Theory. 46, 1869–1887 (2011). https://doi.org/10.1016/j.mechmachtheory.2011.07.010

Wang, S., Huo, M., Zhang, C., Liu, J., Song, Y., Cao, S., Yang, Y.: Effect of mesh phase on wave vibration of spur planetary ring gear. Eur. J. Mech. ASolids. 30, 820–827 (2011). https://doi.org/10.1016/j.euromechsol.2011.06.004

Kang, M.R., Kahraman, A.: An experimental and theoretical study of the dynamic behavior of double-helical gear sets. J. Sound Vib. 350, 11–29 (2015). https://doi.org/10.1016/j.jsv.2015.04.008

Yavuz, S.D., Saribay, Z.B., Cigeroglu, E.: Nonlinear time-varying dynamic analysis of a multi-mesh spur gear train. Conf. Proc. Soc. Exp. Mech. Ser. 4, 309–321 (2016). https://doi.org/10.1007/978-3-319-29763-7_30

Brecher, C., Schroers, M., Löpenhaus, C.: Experimental analysis of the dynamic noise behavior of a two-stage cylindrical gearbox. Prod. Eng. 11, 695–702 (2017). https://doi.org/10.1007/s11740-017-0775-y

Peng, D., Smith, W.A., Randall, R.B., Peng, Z.: Use of mesh phasing to locate faulty planet gears. Mech. Syst. Signal Process. 116, 12–24 (2019). https://doi.org/10.1016/j.ymssp.2018.06.035

Peng, D., Smith, W.A., Borghesani, P., Randall, R.B., Peng, Z.: Comprehensive planet gear diagnostics: use of transmission error and mesh phasing to distinguish localised fault types and identify faulty gears. Mech. Syst. Signal Process. 127, 531–550 (2019). https://doi.org/10.1016/j.ymssp.2019.03.024

Wang, C., Parker, R.G.: Dynamic modeling and mesh phasing-based spectral analysis of quasi-static deformations of spinning planetary gears with a deformable ring. Mech. Syst. Signal Process. 136, 106497 (2020). https://doi.org/10.1016/j.ymssp.2019.106497

Sanchez-Espiga, J., Fernandez-del-Rincon, A., Iglesias, M., Viadero, F.: Planetary gear transmissions load sharing measurement from tooth root strains: numerical evaluation of mesh phasing influence. Mech. Mach. Theory. 163, 104370 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104370

Sanchez-Espiga, J., Fernandez-del-Rincon, A., Iglesias, M., Viadero, F.: Influence of errors in planetary transmissions load sharing under different mesh phasing. Mech. Mach. Theory. 153, 104012 (2020). https://doi.org/10.1016/j.mechmachtheory.2020.104012

Wang, C., Dong, B., Parker, R.G.: Impact of planet mesh phasing on the vibration of three-dimensional planetary/epicyclic gears. Mech. Mach. Theory. 164, 104422 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104422

Wang, C., Parker, R.G.: Nonlinear dynamics of lumped-parameter planetary gears with general mesh phasing. J. Sound Vib. 523, 116682 (2022). https://doi.org/10.1016/j.jsv.2021.116682

Li, Z., Peng, Z.: Nonlinear dynamic response of a multi-degree of freedom gear system dynamic model coupled with tooth surface characters: a case study on coal cutters. Nonlinear Dyn. 84, 271–286 (2016). https://doi.org/10.1007/s11071-015-2475-5

Liu, G., Parker, R.G.: Nonlinear dynamics of idler gear systems. Nonlinear Dyn. 53, 345–367 (2008). https://doi.org/10.1007/s11071-007-9317-z

Vinayak, H., Singh, R., Padmanabhan, C.: Linear dynamic analysis of multi-mesh transmissions containing external, rigid gears. J. Sound Vib. 185, 1–32 (1995). https://doi.org/10.1006/jsvi.1994.0361

Erltenel, T., Parker, R.G.: A static and dynamic model for three-dimensional, multi-mesh gear systems. Proc. ASME Int. Des. Eng. Tech. Conf. Comput. Inf. Eng. Conf. DETC2005. 5, 945–956 (2005). https://doi.org/10.1115/detc2005-85673

Wang, X.: Stability research of multistage gear transmission system with crack fault. J. Sound Vib. 434, 63–77 (2018). https://doi.org/10.1016/j.jsv.2018.07.037

Li, W., Sun, J., Yu, J.: Analysis of dynamic characteristics of a multi-stage gear transmission system. JVC J. Vib. Control. 25, 1653–1662 (2019). https://doi.org/10.1177/1077546319830810

He, X., Zhou, X., Xue, Z., Hou, Y., Liu, Q., Wang, R.: Effects of gear eccentricity on time-varying mesh stiffness and dynamic behavior of a two-stage gear system. J. Mech. Sci. Technol. 33, 1019–1032 (2019). https://doi.org/10.1007/s12206-019-0203-7

Lu, W., Zhang, Y., Cheng, H., Zhou, Y., Lv, H.: Research on dynamic behavior of multistage gears-bearings and box coupling system. Meas. J. Int. Meas. Confed. 150, 107096 (2020). https://doi.org/10.1016/j.measurement.2019.107096

Bai, W., Qin, D., Wang, Y., Lim, T.C.: Dynamic characteristic of electromechanical coupling effects in motor-gear system. J. Sound Vib. 423, 50–64 (2018). https://doi.org/10.1016/j.jsv.2018.02.033

Wang, S., Zhu, R.: An improved mesh stiffness calculation model for cracked helical gear pair with spatial crack propagation path. Mech. Syst. Signal Process. 172, 108989 (2022). https://doi.org/10.1016/j.ymssp.2022.108989

Kahraman, A., Blankenship, G.W.: Effect of involute contact ratio on spur gear dynamics. J. Mech. Des. Trans. ASME. 121, 112–118 (1999). https://doi.org/10.1115/1.2829411

Dai, H., Long, X., Chen, F., Xun, C.: An improved analytical model for gear mesh stiffness calculation. Mech. Mach. Theory. 159, 104262 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104262

Marafona, J.D.M., Marques, P.M.T., Martins, R.C., Seabra, J.H.O.: Mesh stiffness models for cylindrical gears: a detailed review. Mech. Mach. Theory 166, 104472 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104472

Natali, C., Battarra, M., Dalpiaz, G., Mucchi, E.: A critical review on FE-based methods for mesh stiffness estimation in spur gears. Mech. Mach. Theory. 161, 104319 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104319

Ma, H., Song, R., Pang, X., Wen, B.: Time-varying mesh stiffness calculation of cracked spur gears. Eng. Fail. Anal. 44, 179–194 (2014). https://doi.org/10.1016/j.engfailanal.2014.05.018

Xie, C., Hua, L., Han, X., Lan, J., Wan, X., Xiong, X.: Analytical formulas for gear body-induced tooth deflections of spur gears considering structure coupling effect. Int. J. Mech. Sci. 148, 174–190 (2018). https://doi.org/10.1016/j.ijmecsci.2018.08.022

Kahraman, A., Blankenship, G.W.: Experiments on nonlinear dynamic behavior of an oscillator with clearance and periodically time-varying parameters. J. Appl. Mech. Trans. ASME. 64, 217–226 (1997). https://doi.org/10.1115/1.2787276

Kahraman, A., Singh, R.: Non-linear dynamics of a spur gear pair. J. Sound Vib. 142, 49–75 (1990)

Pizzolante, F., Battarra, M., Mucchi, E.: The role of gear layout and meshing phase for whine noise reduction in ordinary geartrains. Mech. Mach. Theory. 181, 105209 (2023). https://doi.org/10.1016/j.mechmachtheory.2022.105209

Acknowledgements

The authors would like to acknowledge the financial support from the NSFC, the research is funded by National Natural Science Foundation of China (Contract No. 51775036), these supports are gracefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

Wei Li and other co-authors declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Li, Z. Dynamic analysis of a multi-stage gear system considering the coupling between mesh phasing angle and coaxial teeth ratio. Nonlinear Dyn 111, 19855–19878 (2023). https://doi.org/10.1007/s11071-023-08896-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08896-8