Abstract

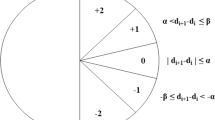

To abstract the fault features from multivariate vibration signals of the rotating machinery under different speeds, an improved multivariate multiscale fuzzy distribution entropy (IMMFDE) is proposed. Based on multivariate empirical mode decomposition, the IMMFDE can determine the maximum scale adaptively, meanwhile eliminate the frequency aliasing and avoid the loss of potentially useful information in the multiscale process. The trait of IMMFDE is verified by calculating the sequences and their amplitude spectrums at each scale of the simulated multivariate signals. Further, the fault diagnosis method is proposed for the rotating machinery under different speeds based on IMMFDE. In the method, the statistical parameters and IMMFDE are calculated as fault feature set; then, support vector machine is used for fault diagnosis. Applying the method to two types of the rotating machinery multi-fault diagnosis under different speeds, the results show the proposed method can obtain better fault diagnosis results.

Similar content being viewed by others

Data availability

The data in the paper are available from the corresponding author upon reasonable request.

References

Tang, S., Yuan, S., Zhu, Y.: Deep learning-based intelligent fault diagnosis methods toward rotating machinery. IEEE Access 8, 9335–9346 (2019). https://doi.org/10.1109/ACCESS.2019.2963092

Jin, Y., Hou, L., Chen, Y.: A time series transformer based method for the rotating machinery fault diagnosis. Neurocomputing 494, 379–395 (2022). https://doi.org/10.1016/j.neucom.2022.04.111

Pan, H., Xu, H., Zheng, J., Tong, J., Cheng, J.: Twin robust matrix machine for intelligent fault identification of outlier samples in roller bearing. Knowl. Based Syst. 252, 109391 (2022). https://doi.org/10.1016/j.knosys.2022.109391

Chinniah, Y.: Analysis and prevention of serious and fatal accidents related to moving parts of machinery. Saf. Sci. 75, 163–173 (2015). https://doi.org/10.1016/j.ssci.2015.02.004

Pan, H., Xu, H., Zheng, J., Su, J., Tong, J.: Multi-class fuzzy support matrix machine for classification in roller bearing fault diagnosis. Adv. Eng. Inform. 51, 101445 (2022). https://doi.org/10.1016/j.aei.2021.101445

Yang, D., Karimi, H.R., Sun, K.: Residual wide-kernel deep convolutional auto-encoder for intelligent rotating machinery fault diagnosis with limited samples. Neural Netw. 141, 133–144 (2021). https://doi.org/10.1016/j.neunet.2021.04.003

Wang, L., Shao, Y.: Fault feature extraction of rotating machinery using a reweighted complete ensemble empirical mode decomposition with adaptive noise and demodulation analysis. Mech. Syst. Signal Process. 138, 106545 (2020). https://doi.org/10.1016/j.ymssp.2019.106545

Li, Y., Wang, X., Si, S., Huang, S.: Entropy based fault classification using the Case Western Reserve University data: a benchmark study. IEEE Trans. Reliab. 69(2), 754–767 (2020). https://doi.org/10.1109/TR.2019.2896240

Minhas, A.S., Kankar, P.K., Kumar, N., Singh, S.: Bearing fault detection and recognition methodology based on weighted multiscale entropy approach. Mech. Syst. Signal Process. 147, 107073 (2021). https://doi.org/10.1016/j.ymssp.2020.107073

Gao, Y., Karimi, M., Kudreyko, A., Song, W.: Spare optimistic based on improved ADMM and the minimum entropy de-convolution for the early weak fault diagnosis of bearings in marine systems. ISA Trans. 78, 98–104 (2018). https://doi.org/10.1016/j.isatra.2017.12.021

Li, Y., Wang, X., Liu, Z., Liang, X., Si, S.: The entropy algorithm and its variants in the fault diagnosis of rotating machinery: a review. IEEE Access 6, 66723–66741 (2018). https://doi.org/10.1109/access.2018.2873782

Guan, Z., Liao, Z., Li, K., Chen, P.: A precise diagnosis method of structural faults of rotating machinery based on combination of empirical mode decomposition, sample entropy, and deep belief network. Sensors 19(3), 591 (2019). https://doi.org/10.3390/s19030591

Chen, W., Wang, Z., Xi, H., Yu, Y.: Characterization of surface EMG signal based on fuzzy entropy. IEEE Trans. Neural Syst. Rehabil. Eng. 15(2), 266–272 (2007). https://doi.org/10.1109/TNSRE.2007.897025

Zheng, J., Cheng, J., Yang, Y.: A rolling bearing fault diagnosis approach based on LCD and fuzzy entropy. Mech. Mach. Theory 70, 441–453 (2013). https://doi.org/10.1016/j.mechmachtheory.2013.08.014

Zhang, T., Chen, W., Li, M.: Fuzzy distribution entropy and its application in automated seizure detection technique. Biomed. Signal Process. 39, 360–377 (2018). https://doi.org/10.1016/j.bspc.2017.08.013

Costa, M., Goldberger, A.L., Peng, C.K.: Multiscale entropy analysis of biological signals. Phys. Rev. E 71(2), 021906 (2005). https://doi.org/10.1103/PhysRevE.71.021906

Hu, T., Cheng, J., Wang, P., Wang, J., Yang, Y.: Extensible and displaceable hyperdisk based classifier for gear fault intelligent diagnosis. Knowl. Based Syst. 204, 106250 (2020). https://doi.org/10.1016/j.knosys.2020.106250

Zhao, X., Cheng, J., Wang, P., He, Z., Shao, H.: A novelty detection scheme for rolling bearing based on multiscale fuzzy distribution entropy and hybrid kernel convex hull approximation. Measurement 156, 107589 (2020)

Ma, Y., Cheng, J., Wang, P., Wang, J., Yang, Y.: Rotating machinery fault diagnosis based on multivariate multiscale fuzzy distribution entropy and Fisher score. Measurement 179, 109495 (2021). https://doi.org/10.1016/j.measurement.2020.107589

Ahmed, M.U., Mandic, D.P.: Multivariate multiscale entropy analysis. IEEE Signal Process. Lett. 19(2), 91–94 (2021). https://doi.org/10.1109/LSP.2011.2180713

Cheng, H., Tao, W., Gu, R., Jin, Z., Ma, R., Qu, H.: Rolling bearing fault diagnosis based on composite multiscale permutation entropy and reverse cognitive fruit fly optimization algorithm—extreme learning machine. Measurement 173, 108636 (2021). https://doi.org/10.1016/j.measurement.2020.108636

Zheng, J., Pan, H., Cheng, J.: Rolling bearing fault detection and diagnosis based on composite multiscale fuzzy entropy and ensemble support vector machines. Mech. Syst. Signal Process. 85, 746–759 (2017). https://doi.org/10.1016/j.ymssp.2016.09.010

Costa, M.D., Goldberger, A.L.: Generalized multiscale entropy analysis: application to quantifying the complex volatility of human heartbeat time series. Entropy 17(3), 1197–1203 (2015). https://doi.org/10.3390/e17031197

Zheng, J., Jiang, Z., Pan, H.: Sigmoid-based refined composite multiscale fuzzy entropy and t-SNE based fault diagnosis approach for rolling bearing. Measurement 129, 332–342 (2018). https://doi.org/10.1016/j.measurement.2018.07.045

Wang, Q., Xiao, Y., Wang, S., Liu, W., Liu, X.: A method for constructing automatic rolling bearing fault identification model based on refined composite multi-scale dispersion entropy. IEEE Access 9, 3089251 (2021). https://doi.org/10.1109/ACCESS.2021.3089251

Ahmed, M.U., Rehman, N., Looney, D., Rutkowski, T.W., Mandic, D.P.: Dynamical complexity of human responses: a multivariate data-adaptive framework. Bull. Pol. Acad. Sci. Tech. Sci. 60(3), 433–445 (2012). https://doi.org/10.2478/v10175-012-0055-0

Long, X., Yang, P., Guo, H., Zhao, Z., Wu, X.: A CBA-KELM-based recognition method for fault diagnosis of wind turbines with time-domain analysis and multisensor data fusion. Shock Vib. 2019, 1–14 (2019). https://doi.org/10.1155/2019/7490750

Elforjani, M., Mba, D.: Accelerated natural fault diagnosis in slow speed bearings with acoustic emission. Eng. Fract. Mech. 77(1), 112–127 (2010). https://doi.org/10.1016/j.engfracmech.2009.09.016

Verma, A., Zhang, Z., Kusiak, A.: Modeling and prediction of gearbox faults with data-mining algorithms. J. Sol. Energy Eng. 135(3), 031007 (2013). https://doi.org/10.1115/1.4023516

Minhas, A.S., Singh, S.: A new bearing fault diagnosis approach combining sensitive statistical features with improved multiscale permutation entropy method. Knowl. Based Syst. 218(17), 106883 (2021). https://doi.org/10.1016/j.knosys.2021.106883

Yin, Z., Hou, J.: Recent advances on SVM based fault diagnosis and process monitoring in complicated industrial processes. Neurocomputing 174, 643–650 (2016). https://doi.org/10.1016/j.neucom.2015.09.081

Wang, Z., Gao, L., Cai, Y.: Rolling bearing fault diagnosis using generalized refined composite multiscale sample entropy and optimized support vector machine. Measurement 156, 107574 (2020). https://doi.org/10.1016/j.measurement.2020.107574

Zhao, D., Liu, S., Gu, D., Sun, X., Wang, L., We, Y., Zhang, H.: Improved multi-scale entropy and it’s application in rolling bearing fault feature extraction. Measurement 152, 107361 (2020). https://doi.org/10.1016/j.measurement.2019.107361

Rehman, N., Mandic, D.P.: Multivariate empirical mode decomposition. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 466(2117), 1291–1302 (2010). https://doi.org/10.1098/rspa.2009.0502

Lv, Y., Yuan, R., Song, G.: Multivariate empirical mode decomposition and its application to fault diagnosis of rolling bearing. Mech. Syst. Signal Process. 81, 219–234 (2016). https://doi.org/10.1016/j.ymssp.2016.03.010

Huang, W., Cheng, J., Yang, Y.: Rolling bearing fault diagnosis and performance degradation assessment under variable operation conditions based on nuisance attribute projection. Mech. Syst. Signal Process. 114, 165–188 (2019). https://doi.org/10.1016/j.ymssp.2018.05.015

Suo, M., Zhu, B., An, R., Sun, H., Xu, S., Yu, Z.: Data-driven fault diagnosis of satellite power system using fuzzy Bayes risk and SVM. Aerosp. Sci. Technol. 84, 1092–1105 (2019). https://doi.org/10.1016/j.ast.2018.11.049

Acknowledgements

This research is supported by National Natural Science Foundation of China (51975193 and 51875183).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest concerning the publication of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, Y., Cheng, J., Wang, P. et al. A new rotating machinery fault diagnosis method for different speeds based on improved multivariate multiscale fuzzy distribution entropy. Nonlinear Dyn 111, 16895–16919 (2023). https://doi.org/10.1007/s11071-023-08609-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08609-1