Abstract

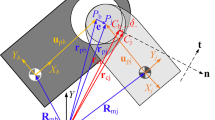

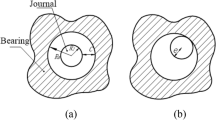

The clearance joint is very important to the nonlinear dynamic characteristics of mechanism. This paper presents a nonlinear dynamic characteristic modeling method of shift manipulator for robot driver to improve dynamic characteristics. Using the improved L-N contact force model and the modified Coulomb friction model, the normal contact force and the tangential contact force of clearance joint are analyzed. With multiple clearance joints, the nonlinear dynamic characteristic model of the shift manipulator for robot driver is established. The nonlinear dynamic characteristic laws of the shift manipulator including the end displacement, velocity, acceleration and active joint driving torque are analyzed by different sizes of clearance joints. And the performance test of the shift manipulator for robot driver is conducted. The results demonstrate that the nonlinear dynamic characteristics are well analyzed and the validity of the modeling method is verified through the presented characteristic model with full clearance joints.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Kim, D.H., Kim, J.W., Choi, S.B.: Design and modeling of energy efficient dual clutch transmission with ball-ramp self-energizing mechanism. IEEE Trans. Veh. Technol. 69, 2525–2536 (2020). https://doi.org/10.1109/TVT.2019.2963332

Kim, W.S., Kim, Y.J., Kim, Y.S., Baek, S.Y., Baek, S.M., Lee, D.H., Nam, K.C., Kim, T.B., Lee, H.J.: Development of control system for automated manual transmission of 45-kW agricultural tractor. Appl. Sci. 10, 2930–2950 (2020). https://doi.org/10.3390/app10082930

Chen, G., Zhang, W.G.: Hierarchical coordinated control method for unmanned robot applied to automotive test. IEEE Trans. Ind. Electron. 63, 1039–1051 (2016). https://doi.org/10.1109/TIE.2015.2477266

Chen, G., Chen, S.B., Langari, R., Li, X., Zhang, W.G.: Driver-behavior-based adaptive steering robust nonlinear control of unmanned driving robotic vehicle with modeling uncertainties and disturbance observer. IEEE Trans. Veh. Technol. 68, 8183–8190 (2019). https://doi.org/10.1109/TVT.2019.2922452

Yechiel, O., Guterman, H.: IVO robot driver. In: 2016 IEEE 84th Vehicular Technology Conference (VTC-Fall), pp. 1–5 (2016). https://doi.org/10.1109/VTCFall.2016.7881054

Huang, X., Zhang, S., Peng, H.: Developing robot driver etiquette based on naturalistic human driving behavior. IEEE Trans. Intell. Transp. Syst. 21(4), 1393–1403 (2020). https://doi.org/10.1109/tits.2019.2913102

Zhu, Y.H., Fu, Z.Y., Fu, Z., Chen, X., Wu, Q.: Multi-features fusion for fault diagnosis of pedal robot using time-speed signals. Sensors 19(1), 163 (2019). https://doi.org/10.3390/s19010163

Hirata, N., Mizutani, N., Matsui, H., Yano, K., Takahashi, T.: Fuel consumption in a driving test cycle by robotic driver considering system dynamics. In: 2015 IEEE International Conference on Robotics and Automation (ICRA). Seattle, WA, USA, pp. 3374–3379 (2015). https://doi.org/10.1109/icra.2015.7139665

Chen, G., Zhang, W.G., Yu, B.: Multibody dynamics modeling of electromagnetic direct-drive vehicle robot driver. Int. J. Adv. Robotic Syst. 14(5) (2017). https://doi.org/10.1177/1729881417731896

Lu, W., Chen, H., Wang, L.: Motion analysis of tractor robot driver’s gear shift mechanical arm. Trans. Chin. Soc. Agric. Mach. 47(1), 37–44 (2016). https://doi.org/10.6041/j.issn.1000-1298.2016.01.006

Yu, S.L., Chen, G.: Rigid-flexible coupling kinematics analysis of shifting manipulator for robot driver. Automot. Eng. 40(6), 733–740 (2018). https://doi.org/10.19562/j.chinasae.qcgc.2018.06.017

Mizutani, N., Ishida, Y., Matsui, H., Yano, K., Takahashi, T.: Automatic driving control by robotic driver considering the lack of a driving force at changing gears. In: IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). Daejeon, Korea (South), pp. 3075–3080 (2016). https://doi.org/10.1109/iros.2016.7759476

Chu, C.C., Wang, D., Zhang, W.G., Xu, T.: Speed control of electric vehicle driving robot based on inverse control strategy model. Automot. Eng. 42(09), 1166–1173 (2020). https://doi.org/10.19562/j.chinasae.qcgc.2020.09.004

Zhou, N., Chen, G.: Dynamic analysis of gear shifting manipulator based on neural network load fluctuation simulation. China Mech. Eng. 31(4), 472–481 (2020). https://doi.org/10.3969/j.issn.1004-132X.2020.04.015

Yu, L.Y., Zheng, S., Chang, J.H., Liu, X.X.: Pedal actuator of driver robot based on flexible manipulator. In: ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC/CIE). Cleveland, Ohio, USA (2017). https://doi.org/10.1115/DETC2017-68100

Wu, X.Z.: Dynamic analysis of the double crank mechanism with a 3D translational clearance joint employing a variable stiffness contact force model. Nonlinear Dyn. 99(5), 1937–1958 (2020). https://doi.org/10.1007/s11071-019-05419-2

Qian, M.B., Qin, Z., Yan, S.Z., Zhang, L.: A comprehensive method for the contact detection of a translational clearance joint and dynamic response after its application in a crank-slider mechanism. Mech. Mach. Theory. 145 (2020). https://doi.org/10.1016/j.mechmachtheory.2019.103717

Zhang, H.D., Zhang, X.M., Zhang, X.C., Mo, J.S.: Dynamic analysis of a 3-PRR parallel mechanism by considering joint clearances. Nonlinear Dyn. 90(1), 405–423 (2017). https://doi.org/10.1007/s11071-017-3672-1

Lv, T.Q., Zhang, Y.Q., Duan, Y.P., Yang, J.: Kinematics & compliance analysis of double wishbone air suspension with frictions and joint clearances. Mech. Mach. Theory. 156 (2021). https://doi.org/10.1016/J.MECHMACHTHEORY.2020.104127

Xiang, W.W.K., Yan, S.Z., Wu, J.N., Niu, W.D.: Dynamic response and sensitivity analysis for mechanical systems with clearance joints and parameter uncertainties using Chebyshev polynomials method. Mech. Syst. Signal Process. 138 (2020). https://doi.org/10.1016/j.ymssp.2019.106596

Zhan, Z.H., Zhang, X.M., Zhang, H.D., Chen, G.C.: Unified motion reliability analysis and comparison study of planar parallel manipulators with interval joint clearance variables. Mech. Mach. Theory 138, 58–75 (2019). https://doi.org/10.1016/j.mechmachtheory.2019.03.041

Zhu, A.B., He, S.L., Zhao, J.W., Luo, W.C.: A nonlinear contact pressure distribution model for wear calculation of planar revolute joint with clearance. Nonlinear Dyn. 88(1), 315–328 (2017). https://doi.org/10.1007/s11071-016-3244-9

Fang, C.C., Meng, X.H., Lu, Z.J., Wu, G., Tang, D.H., Zhao, B.: Modeling a lubricated full-floating pin bearing in planar multibody systems. Tribol. Int. 131, 222–237 (2019). https://doi.org/10.1016/j.triboint.2018.10.045

Wang, Z., Tian, Q., Hu, H.Y., Flores, P.: Nonlinear dynamics and chaotic control of a flexible multibody system with uncertain joint clearance. Nonlinear Dyn. 86(3), 1571–1597 (2016). https://doi.org/10.1007/s11071-016-2978-8

Li, Y.Y., Wang, C., Huang, W.H.: Dynamics analysis of planar rigid-flexible coupling deployable solar array system with multiple revolute clearance joints. Mech. Syst. Signal Process. 117, 188–209 (2019). https://doi.org/10.1016/j.ymssp.2018.07.037

Tian, Q., Flores, P., Lankarani, H.M.: A comprehensive survey of the analytical, numerical and experimental methodologies for dynamics of multibody mechanical systems with clearance or imperfect joints. Mech. Mach. Theory. 122, 1–57 (2018). https://doi.org/10.1016/j.mechmachtheory.2017.12.002

Sun, D.Y., Shi, Y., Zhang, B.Q.: Robust optimization of constrained mechanical system with joint clearance and random parameters using multi-objective particle swarm optimization. Struct. Multidiscip. Optim. 58(5), 2073–2084 (2018). https://doi.org/10.1007/s00158-018-2021-4

Yang, Y.L., Cheng, J.J.R., Zhang, T.Q.: Vector form intrinsic finite element method for planar multibody systems with multiple clearance joints. Nonlinear Dyn. 86(1), 421–440 (2016). https://doi.org/10.1007/s11071-016-2898-7

Zheng, X.D., Zhang, F., Wang, Q.: Modeling and simulation of planar multibody systems with revolute clearance joints considering stiction based on an LCP method. Mech. Mach. Theory 130, 184–202 (2018). https://doi.org/10.1016/j.mechmachtheory.2018.08.017

Li, L., Zhu, X.J.: Design of compliant revolute joints based on mechanism stiffness matrix through topology optimization using a parameterization level set method. Struct. Multidiscip. Optim. 60(4), 1475–1489 (2019). https://doi.org/10.1007/s00158-019-02278-8

Varedi, S.M., Daniali, H.M., Dardel, M., Fathi, A.: Optimal dynamic design of a planar slider-crank mechanism with a joint clearance. Mech. Mach. Theory 86, 191–200 (2015). https://doi.org/10.1016/j.mechmachtheory.2014.12.008

Lai, X.M., He, H., Lai, Q.F., Wang, C., Yang, J.H., Zhang, Y., Fang, H.Y., Liao, S.R.: Computational prediction and experimental validation of revolute joint clearance wear in the low-velocity planar mechanism. Mech. Syst. Signal Process. 85, 963–976 (2017). https://doi.org/10.1016/j.ymssp.2016.09.027

Chen, X.L., Gao, W.H., Deng, Y., Wang, Q.: Chaotic characteristic analysis of spatial parallel mechanism with clearance in spherical joint. Nonlinear Dyn. 94(4), 2625–2642 (2018). https://doi.org/10.1007/s11071-018-4513-6

Erkaya, S., Doğan, S., Ulus, Ş: Effects of joint clearance on the dynamics of a partly compliant mechanism: numerical and experimental studies. Mech. Mach. Theory 88, 125–140 (2015). https://doi.org/10.1016/j.mechmachtheory.2015.02.007

Natsiavas, S.: Analytical modeling of discrete mechanical systems involving contact, impact, and friction. Appl. Mech. Rev. 71(5), 050802 (2019). https://doi.org/10.1115/1.4044549

Khan, Z.A., Chacko, V., Nazir, H.: A review of friction models in interacting joints for durability design. Friction. 5, 1–22 (2017). https://doi.org/10.1007/s40544-017-0143-0

Chen, X.L., Jiang, S.A., Deng, Y., Wang, Q.: Dynamics analysis of 2-DOF complex planar mechanical system with joint clearance and flexible links. Nonlinear Dyn. 93(3), 1009–1034 (2018). https://doi.org/10.1007/s11071-018-4242-x

Guo, J.N., He, P., Liu, Z.S., Huang, H.Y.: Investigation of an improved planar revolute clearance joint contact model with rough surface. Tribol. Int. 134, 385–393 (2019). https://doi.org/10.1016/j.triboint.2019.02.019

Zhao, B., Zhou, K., Xie, Y.B.: A new numerical method for planar multibody system with mixed lubricated revolute joint. Int. J. Mech. Sci. 113, 105–119 (2016). https://doi.org/10.1016/j.ijmecsci.2016.04.016

Wang, G.X., Wang, L.: Dynamics investigation of spatial parallel mechanism considering rod flexibility and spherical joint clearance. Mech. Mach. Theory 137, 83–107 (2019). https://doi.org/10.1016/j.mechmachtheory.2019.03.017

Tang, L.L., Liu, J.Y.: Modeling and analysis of sliding joints with clearances in flexible multibody systems. Nonlinear Dyn. 94(4), 2423–2440 (2018). https://doi.org/10.1007/s11071-018-4500-y

Khashaba, U.A., Sebaey, T.A., Selmy, A.I.: Experimental verification of a progressive damage model for composite pinned-joints with different clearances. Int. J. Mech. Sci. 152, 481–491 (2019). https://doi.org/10.1016/j.ijmecsci.2019.01.023

Song, N.N., Peng, H.J., Xu, X.M., Wang, G.: Modeling and simulation of a planar rigid multibody system with multiple revolute clearance joints based on variational inequality. Mech. Mach. Theory 154 (2020). https://doi.org/10.1016/j.mechmachtheory.2020.104053

Sun, D.Y., Zhang, B.Q., Liang, X.F., Shi, Y., Suo, B.: Dynamic analysis of a simplified flexible manipulator with interval joint clearances and random material properties. Nonlinear Dyn. 98(2), 1049–1063 (2019). https://doi.org/10.1007/s11071-019-05248-3

Zhao, B., Zhang, Z.N., Fang, C.C., Dai, X.D., Xie, Y.B.: Modeling and analysis of planar multibody system with mixed lubricated revolute joint. Tribol. Int. 98, 229–241 (2016). https://doi.org/10.1016/j.triboint.2016.02.024

Ma, J., Qian, L.F.: Modeling and simulation of planar multibody systems considering multiple revolute clearance joints. Nonlinear Dyn. 90(3), 1907–1940 (2017). https://doi.org/10.1007/s11071-017-3771-z

Pi, T., Zhang, Y.Q.: Simulation of planar mechanisms with revolute clearance joints using the multipatch based isogeometric analysis. Comput. Methods Appl. Mech. Eng. 343(1), 453–489 (2019). https://doi.org/10.1016/j.cma.2018.08.039

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51675281); the Fundamental Research Funds for the Central Universities (Grant No. 30918011101); the Six Talents Peak Project of Jiangsu Province (Grant 2015-JXQC-003).

Funding

This study was funded by the National Natural Science Foundation of China (NSFC); the Fundamental Research Funds for the Central Universities (NRFCU); and the Six Talents Peak Project of Jiangsu Province (STPPJP).

Author information

Authors and Affiliations

Contributions

Chen developed and tested the robot driver, analyzed the data, and wrote this manuscript. Xu established the characteristic model, conducted the dynamic analysis, and wrote this manuscript. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, G., Xu, X. A nonlinear dynamic characteristic modeling method of shift manipulator for robot driver with multiple clearance joints. Nonlinear Dyn 110, 219–236 (2022). https://doi.org/10.1007/s11071-022-07652-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-022-07652-8