Abstract

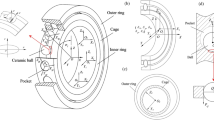

The frequent impulse collisions and wear between the ball and cage pocket not only affect the bearing stability but also significantly impact the deterioration of the bearing service life. A comprehensive dynamic model for analyzing the stability, skidding degree, ball–cage collision, wear distribution, and wear rate of four types of cage pocket is proposed. A series of tests of cage whirling conducted on self-lubricating bearing test bench using high-speed photographic technology have proven the accuracy of the model. It is found that the cage with a combination of circle and rectangle pockets has the highest stability. The circle pocket has a larger collision area and higher wear rate than rectangle and diamond pockets. The combined rectangle–diamond pocket has a better wear resistance.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

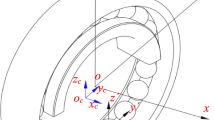

- \(\left({x}_{r},{y}_{r},{z}_{r}\right)\) :

-

Bearing global coordinate system

- \(\left({x}_{c},{y}_{c},{z}_{c}\right)\) :

-

Cage coordinate system

- \(\left({x}_{b},{y}_{b},{z}_{b}\right)\) :

-

Rolling element coordinate system

- \(\left({x}_{p},{y}_{p},{z}_{p}\right)\) :

-

Cage pocket reference system

- \(\left({x}_{h},{y}_{h}\right)\) :

-

Hertzian contact area reference system

- j :

-

Subscripts for jth rolling element or cage segment

- i :

-

Subscripts for inner ring

- o :

-

Subscripts for outer ring

- \({a}_{p},{b}_{p}\) :

-

Long and short axis of the contact ellipse

- \(A(m,n)\) :

-

Area of the (mth, nth) discretized Hertzian contact patch

- \(C, {K}_{0}^{^{\prime}}, {K}_{0}\) :

-

Lubricant parameter under certain operating conditions

- \({c}_{p}\) :

-

The viscous damping coefficient

- \({D}_{m}\) :

-

Bearing pitch diameter

- D b :

-

Ball diameter

- \({D}_{p}\) :

-

Cage pocket diameter

- \(E,\upsilon \) :

-

Young’s modulus and Poisson’s ratio

- \({E}_{bp}\) :

-

Effective elasticity modulus for ball–pocket pair

- \({F}_{a},{F}_{r}\) :

-

External force on the bearing

- \({F}_{p}\) :

-

Normal contact force

- \({F}_{g}\), \({f}_{g}\) :

-

Contact normal and tangential force of the cage-guide ring rubbing

- \({F}_{c}\) :

-

Cage force

- \({f}_{h}\) :

-

Friction force of ball–cage pocket

- \({h}_{p}\) :

-

Oil film thickness

- \({h}_{c}\) :

-

Radial height position of the collision point

- \(H\) :

-

The Brinell hardness

- \({K}_{c}\) :

-

Contact stiffness

- \({K}_{w}\) :

-

The Archard wear coefficients

- \({L}_{r},{L}_{z}\) :

-

Displacements of the center position of the rolling elements

- \({m}_{c}\) :

-

Ball and cage mass

- \({m}_{node}\),\({n}_{node}\) :

-

Discretized node number of Hertzian contact area

- \({N}_{b}\) :

-

Number of rolling elements

- \(Q\) :

-

Contact force

- \({q}_{p}\) :

-

The discretize contact pressure

- \({r}_{p}\) :

-

Curvature radius

- \(R\) :

-

Distance between ball center and node of contact patch

- S :

-

Area of contact patch

- t :

-

Operating time

- \(\Delta {V}_{h}\) :

-

Ball–pocket relatively friction speed

- \({V}_{c}\) :

-

Relative revolution tangential speed of the cage and ball

- \({w}_{rate}\) :

-

Wear rate

- \(\alpha \) :

-

Contact angle

- \(\gamma \) :

-

Angle of the cage-guide ring contact force

- \({\delta }_{p}\) :

-

The ball–pocket collision deformation

- \({\mu }_{0}\) :

-

Oil viscosity at a reference temperature

- \(\mu \) :

-

Oil viscosity

- \(\theta \) :

-

Pocket angular position

- \({\theta }_{b}\) :

-

Ball angular position

- \(\lambda \) :

-

Constant to determine whether the cage collides with ball

- \({\omega }_{x},{\omega }_{y}, {\omega }_{z}\) :

-

Ball self-rotation speed

- \({\omega }_{m}\) :

-

Ball orbital rotating speed

- \({\omega }_{th}\) :

-

Cage rotation speed as the rolling element under pure rolling

- \({\omega }_{c}\) :

-

Cage rotating speed

- \(\psi \) :

-

Angle of contact point in the pocket coordinate system

References

Cocks, M., Tallian, T.E.: Sliding contacts in rolling bearings. A S L E Trans. 14, 32–40 (1971). https://doi.org/10.1080/05698197108983225

Liu, Y., Wang, W., Qing, T., Zhang, Y., Liang, H., Zhang, S.: The effect of lubricant temperature on dynamic behavior in angular contact ball bearings. Mech. Mach. Theory. (2020). https://doi.org/10.1016/j.mechmachtheory.2020.103832

Gao, S., Han, Q., Jiang, Z., Zhang, X., Pennacchi, P., Chu, F.: Triboelectric based high-precision self-powering cage skidding sensor and application on main bearing of jet engine. Nano Energy 99, 107387 (2022). https://doi.org/10.1016/j.nanoen.2022.107387

Ruan, H., Zhang, Y., Li, S., Yang, L., Wang, C., Wang, T., Wang, Q.: Effect of temperature on the friction and wear performance of porous oil-containing polyimide. Tribol. Int. (2021). https://doi.org/10.1016/j.triboint.2021.106891

Zhang, D., Wang, C., Qing, T., Wang, Q., Wang, T.: Research progress of porous polymer bearing retainer materials used in aerospace. Jixie Gongcheng Xuebao/J. Mech. Eng. 54, 17–26 (2018). https://doi.org/10.3901/JME.2018.09.017

Wang, J., Zhao, H., Huang, W., Wang, X.: Investigation of porous polyimide lubricant retainers to improve the performance of rolling bearings under conditions of starved lubrication. Wear 380–381, 52–58 (2017). https://doi.org/10.1016/j.wear.2017.03.008

Gao, S., Chatterton, S., Pennacchi, P., Han, Q., Chu, F.: Skidding and cage whirling of angular contact ball bearings: kinematic-hertzian contact-thermal-elasto-hydrodynamic model with thermal expansion and experimental validation. Mech. Syst. Signal Process. 166, 108427 (2022). https://doi.org/10.1016/j.ymssp.2021.108427

Choe, B., Kwak, W., Jeon, D., Lee, Y.: Experimental study on dynamic behavior of ball bearing cage in cryogenic environments, Part II: effects of cage mass imbalance. Mech. Syst. Signal Process. 116, 25–39 (2019). https://doi.org/10.1016/j.ymssp.2018.06.034

Ashtekar, A., Sadeghi, F.: A new approach for including cage flexibility in dynamic bearing models by using combined explicit finite and discrete element methods. J. Tribol. Doi (2012). https://doi.org/10.1115/1.4007348

Li, H., Li, H., Liu, Y., Liu, H.: Dynamic characteristics of ball bearing with flexible cage lintel and wear. Eng. Fail. Anal. 117, 104956 (2020). https://doi.org/10.1016/j.engfailanal.2020.104956

Kwak, W., Lee, J., Lee, Y.B.: Theoretical and experimental approach to ball bearing frictional characteristics compared with cryogenic friction model and dry friction model. Mech. Syst. Signal Process. 124, 424–438 (2019). https://doi.org/10.1016/j.ymssp.2019.01.056

Liu, Y.B., Deng, Z.H., Sang, D.Y.: Hign-speed dynamic performance of cylindrical roller bearing with V-shape pocket. Acta Aeronaut. Astronaut. Sin. 42, 424135 (2021)

Chen, S., Chen, X., Shuai, Q., Gu, J.: Effects of cage pocket shapes on dynamics of angular contact ball bearings. Tribol. Online 15, 343–355 (2020). https://doi.org/10.2474/TROL.15.343

Choe, B., Lee, J., Jeon, D., Lee, Y.: Experimental study on dynamic behavior of ball bearing cage in cryogenic environments, Part I: effects of cage guidance and pocket clearances. Mech. Syst. Signal Process. 115, 545–569 (2019). https://doi.org/10.1016/j.ymssp.2018.06.018

Gupta, P.K.: Modeling of instabilities induced by cage clearances in ball bearings. Tribol. Trans. 34, 93–99 (1991). https://doi.org/10.1080/10402009108982014

Guang, Z., Qiang, B., Chun-jiang, Z., Yu-feng, Y., Yi-jie, F.: Analysis of stability and vibration characteristics of angular contact ball bearing cage under variable parameters. Chin. J. Eng. Des. 27, 735–743 (2020). https://doi.org/10.3785/j.issn.1006-754X.2020.00.090

Cui, Y., Deng, S., Niu, R., Chen, G.: Vibration effect analysis of roller dynamic unbalance on the cage of high-speed cylindrical roller bearing. J. Sound Vib. 434, 314–335 (2018). https://doi.org/10.1016/j.jsv.2018.08.006

Niu, L.: A simulation study on the effects of race surface waviness on cage dynamics in high-speed ball bearings. J. Tribol. (2019). https://doi.org/10.1115/1.4042656

Su, S., Cao, H., Zhang, Y.: Dynamic modeling and characteristics analysis of cylindrical roller bearing with the surface texture on raceways. Mech. Syst. Signal Process. 158, 107709 (2021). https://doi.org/10.1016/j.ymssp.2021.107709

Gao, S., Chatterton, S., Pennacchi, P., Chu, F.: Behaviour of an angular contact ball bearing with three-dimensional cubic-like defect: a comprehensive non-linear dynamic model for predicting vibration response. Mech. Mach. Theory. 163, 104376 (2021). https://doi.org/10.1016/j.mechmachtheory.2021.104376

Ma, F., Jiang, F., An, Q.: Simulation of hydrodynamic lubrication between cage pockets and rollers in cylindrical roller bearings. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 229, 2551–2560 (2015). https://doi.org/10.1177/0954406214562462

Tu, W., Luo, Y., Yu, W.: Dynamic interactions between the rolling element and the cage in rolling bearing under rotational speed fluctuation conditions. J. Tribol. (2019). https://doi.org/10.1115/1.4044082

Liu, Y., Wang, W., Liang, H., Qing, T., Wang, Y., Zhang, S.: Nonlinear dynamic behavior of angular contact ball bearings under microgravity and gravity. Int. J. Mech. Sci. (2020). https://doi.org/10.1016/j.ijmecsci.2020.105782

Chen, L., Xia, X., Zheng, H., Qiu, M.: Chaotic dynamics of cage behavior in a high-speed cylindrical roller bearing. Shock Vib. (2016). https://doi.org/10.1155/2016/9120505

Ye, Z., Li, W., Qu, X., Xiong, Z.: Effect of elliptical pocket on cage dynamic performance of high speed ball bearings. Mach. Des. Manuf. 6, 184–188 (2016). https://doi.org/10.19356/j.cnki.1001-3997.2016.06.049

Koike, H., Kida, K., Mizobe, K., Shi, X., Oyama, S.: Wear of hybrid radial bearings (PEEK ring-PTFE retainer and alumina balls) under dry rolling contact. Tribol. Int. 90, 77–83 (2015). https://doi.org/10.1016/j.triboint.2015.04.007

Wang, A., Yan, S., Lin, B., Zhang, X., Zhou, X.: Aqueous lubrication and surface microstructures of engineering polymer materials (PEEK and PI) when sliding against Si3N4. Friction 5, 414–428 (2017). https://doi.org/10.1007/s40544-017-0155-9

Gao, S., Han, Q., Zhou, N., Pennacchi, P., Chu, F.: Stability and skidding behavior of spacecraft porous oil-containing polyimide cages based on high-speed photography technology. Tribol. Int. 165, 107294 (2022). https://doi.org/10.1016/j.triboint.2021.107294

Dahiwal, R., Thielen, S., Sauer, B.: Modeling and simulation of cage wear in solid-lubricated rolling bearings. Tribol. Online 15, 25–35 (2020). https://doi.org/10.2474/trol.15.25

Zhang, T., Chen, X., Gu, J., Zhao, L.: Analysis on the unstable movement mechanism of high-speed angular contact ball bearing cages. Zhendong yu Chongji/J. Vib. Shock (2019). https://doi.org/10.13465/j.cnki.jvs.2019.10.035

Pasdari, M., Gentle, C.R.: Effect of lubricant starvation on the minimum load condition in a thrust-loaded ball bearing. A S L E Trans. 30, 355–359 (1987). https://doi.org/10.1080/05698198708981767

Gao, S., Chatterton, S., Naldi, L., Pennacchi, P.: Ball bearing skidding and over-skidding in large-scale angular contact ball bearings: nonlinear dynamic model with thermal effects and experimental results. Mech. Syst. Signal Process. 147, 107120 (2021). https://doi.org/10.1016/j.ymssp.2020.107120

Abele, E., Holland, L.: Image-based movement analysis of bearing cages of cylindrical hybrid roller bearings. J. Tribol. (2017). https://doi.org/10.1115/1.4036320

Yang, Z., Chen, H., Yu, T., Li, B., Yang, Z., Chen, H., Yu, T., Li, B.: A high-precision instrument for analyzing nonlinear dynamic behavior of bearing cage A high-precision instrument for analyzing nonlinear dynamic behavior of bearing cage. 085105 (2016). https://doi.org/10.1063/1.4960094

Qiu, Y., Wang, Q., Wang, C., Wang, T.: Oil-containing and tribological properties of porous polyimide containing lubricant oil. Tribology 32, 538–543 (2012)

Gao, S., Han, Q., Zhou, N., Pennacchi, P., Chatterton, S., Qing, T., Zhang, J., Chu, F.: Experimental and theoretical approaches for determining cage motion dynamic characteristics of angular contact ball bearings considering whirling and overall skidding behaviors. Mech. Syst. Signal Process. 168, 108704 (2022). https://doi.org/10.1016/j.ymssp.2021.108704

Hunt, K.H., Crossley, F.R.E.: Coefficient of restitution interpreted as damping in vibroimpact. J. Appl. Mech. 42, 440–445 (1975). https://doi.org/10.1115/1.3423596

Huang, X., Xiang, H., Zheng, W., Chen, Z., Feng, Z.: Experimental study and verification of absolute coefficient of restitution. Lab. Sci. 21, 63–66 (2018)

Brewe, D.E., Hamrock, B.J.: Simplified solution for point contact deformation between two elastic solids. NASA Tech. Memo. 8 (1976). https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760019429.pdf

Hamrock, B.J., Dowson, D.: Ball Bearing Lubrication: The Elastohydrodynamics of Elliptical Contacts. Wiley, New York (1981)

Taylor, P., Gupta, P.K., Forster, N.H.: Modeling of wear in a solid-lubricated ball bearing modeling of wear in a solid-lubricated ball bearing. 37–41 (2008). https://doi.org/10.1080/05698198708981730

Li, H., Li, H., Liu, Y., Liu, H.: Dynamic characteristics of ball bearing with flexible cage lintel and wear. Eng. Fail. Anal. (2020). https://doi.org/10.1016/j.engfailanal.2020.104956

Bi, Z., Mueller, D.W., Zhang, C.W.J.: State of the art of friction modelling at interfaces subjected to elastohydrodynamic lubrication (EHL). Friction 9, 207–227 (2021). https://doi.org/10.1007/s40544-020-0449-1

Funding

This research was supported in part by a scholarship from the China Scholarship Council (CSC) under Grant CSC N° 201806880007, National Science Foundation of China under Grant No. 11872222, and the State Key Laboratory of Tribology under Grant No. SKLT2021D11.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, S., Han, Q., Zhou, N. et al. Dynamic and wear characteristics of self-lubricating bearing cage: effects of cage pocket shape. Nonlinear Dyn 110, 177–200 (2022). https://doi.org/10.1007/s11071-022-07611-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-022-07611-3