Abstract

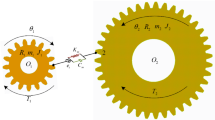

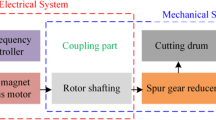

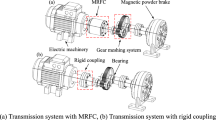

In this paper, the electromechanical coupling torsional resonance characteristics of the multistage gear transmission system driven by the low-speed and high-power permanent magnet synchronous motor (PMSM) are studied. Considering the PMSM electromagnetic effect and bending-torsional vibration characteristics, the mechanical-electromagnetic coupling dynamic model suitable for the speed change process is established. Then, the PMSM electromagnetic stiffness and damping characteristics are analyzed through theoretical derivation. On the basis of electromagnetic stiffness, the influence law of electromagnetic effect on the gear transmission system natural frequency and vibration characteristics is revealed systematically. By both of Campbell diagram and modal energy distribution, the potential resonance points under the influence of internal and external excitation are initially acquired. Ultimately, the potential resonance points are identified by frequency sweep analysis and time domain simulation, and the energy concentration components at resonance point are further analyzed. The results show that the electromagnetic effect reduces the first-order natural frequency and has little influence on others. Moreover, the semi-direct drive cutting transmission system in this paper has the resonance risk caused by the gear time-varying meshing stiffness when the PMSM speed is close to 330 r/min, which should be paid more attention in actual operation. This study can provide some guidance for the design and speed regulation of the gear drive system driven by high-power PMSM.

Similar content being viewed by others

References

Tang, X., Yang, W., Hu, X.: A novel simplified model for torsional vibration analysis of a series-parallel hybrid electric vehicle. Mech. Syst. Signal Pr. 85, 329–338 (2017)

Chen, H.T., Wang, X.H., Gao, H.C.: Dynamic characteristics of wind turbine gear transmission system with random wind and the effect of random backlash on system stability. P. I. Mech. Eng. C-J Mec. 231(14), 2590–2597 (2016)

Shi, P.M., Han, D.Y., Liu, B.: Chaos and chaotic control in a relative rotation nonlinear dynamical system under parametric excitation. Chinese Phys B 19(9), 112–117 (2010)

Jiang, S., Li, W., Sheng L.C.: Nonlinear torsional vibration analysis and control of semidirect electromechanical coupling transmission system in shearer. Shock Vib. (2019)

Teng, W., Jiang, R., Ding, X.: Detection and quantization of bearing fault in direct drive wind turbine via comparative analysis. Shock Vib. (2016)

Bilgin, N., Demircin, M.A., Copur, H.: Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int. J. Rock Ch. Min. 43, 139–156 (2006)

Wei, Q., Wang, X.Y.: Chaos controlling of permanent magnet synchronous motor base on dither signal. J. Vib. Control 19(16), 2541–2550 (2013)

Sheng, L.C., Li, W., Jiang, S.: Nonlinear torsional vibration analysis of motor rotor system in shearer semi-direct drive cutting unit under electromagnetic and load excitation. Nonlinear Dynam. 96(2), 1677–1691 (2019)

Qiu, X., Han, Q., Chu, F.: Dynamic modeling and analysis of the planetary gear under pitching base motion. Int. J. Mech. Sci 141, 31–45 (2018)

Zhang, X., Yu, S.D.: Torsional vibration of crank shaft in an engine–propeller nonlinear dynamical system. J. Sound Vib. 319(1–2), 491–514 (2009)

Sheng, L.C., Li, W., Wang, Y.Q.: Sensorless control of a shearer short-range cutting interior permanent magnet synchronous motor based on a new sliding mode observer. IEEE Access 51, 8439–18450 (2017)

Li, Z., Peng, Z.: Nonlinear dynamic response of a multi-degree of freedom gear system dynamic model coupled with tooth surface characters: a case study on coal cutters. Nonlinear Dyn. 84(1), 271–286 (2016)

Liu, S., Ai, H., Lin, Z.: Analysis of vibration characteristics and adaptive continuous perturbation control of some torsional vibration system with backlash. Chaos Solitons Frac. 103, 151–158 (2017)

Feki, N., Clerc, G., Velex, P.: An integrated electro-mechanical model of motor-gear units-applications to tooth fault detection by electric measurements. Mech. Syst. Signal Pr. 29, 377–390 (2012)

Li, Z., Zheng, L., Gao, W.: Electromechanical coupling mechanism and control strategy for in-wheel-motor-driven electric vehicles. IEEE Trans. Ind. Electron. 66(6), 4524–4533 (2018)

Yang, X., Lu, D., Zhang, J.: Dynamic electromechanical coupling resulting from the air-gap fluctuation of the linear motor in machine tools. Int. J. Mach. Tool Manu. 94, 100–108 (2015)

Szolc, T., Konowrocki, R., Michajłow, M.: An investigation of the dynamic electromechanical coupling effects in machine drive systems driven by asynchronous motors. Mech. Syst. Signal Pr. 49(1–2), 118–134 (2014)

Tan, J., Zhu, C., Song, C.: Study on the dynamic modeling and natural characteristics of wind turbine drivetrain considering electromagnetic stiffness. Mech. Mach. Theory 134, 541–561 (2019)

Bai, W., Qin, D., Wang, Y.: Dynamic characteristic of electromechanical coupling effects in motor-gear system. J. Sound Vib. 423, 50–64 (2018)

Kambrath, J.K., Yoon, C., Mathew, J.: Mitigation of resonance vibration effects in marine propulsion. IEEE T. Ind. Electron. 66(8), 6159–6169 (2018)

Huo, J., Wu, H., Sun, W.: Electromechanical coupling dynamics of TBM main drive system. Nonlinear Dyn. 90(4), 2687–2710 (2017)

Yi, Y.Y., Qin, D.T., Liu, C.: Investigation of electromechanical coupling vibration characteristics of an electric drive multistage gear system. Mech. Mach. Theory 121, 446–459 (2018)

Xie, B., Wang, S., Wang, Y.: Magnetically induced rotor vibration in dual-stator permanent magnet motors. J. Sound Vib. 347, 184–199 (2015)

Chang, S.C., Lin, B.C., Lue, Y.F.: Dither signal effects on quenching chaos of a permanent magnet synchronous motor in electric vehicles. J. Vib. Control 17(12), 1912–1918 (2011)

Chen, X., Wei, H., Deng, T.: Investigation of electromechanical coupling torsional vibration and stability in a high-speed permanent magnet synchronous motor driven system. Appl. Math. Model. 64, 235–248 (2018)

Ju, J.Y., Li, W., Wang, Y.Q.: Dynamics and nonlinear feedback control for torsional vibration bifurcation in main transmission system of scraper conveyor direct-driven by high-power PMSM. Nonlinear Dyn. 93(2), 307–321 (2018)

Wang, X., Suh, C.S.: Nonlinear time-frequency control of PM synchronous motor instability applicable to electric vehicle application. Int. J. Dyn. Control 4(4), 400–412 (2016)

Sheng, L.C., Li, W., Xin, G.F.: Nonlinear torsional vibration analysis and nonlinear feedback control of complex permanent magnet semidirect drive cutting system in coal cutters. Complexity (2019)

Neimark, J.I.: Mathematical models in natural science and engineering. Springer, Berlin, Germany (2012)

Wan, Z., Cao, H., Zi, Y.: Mesh stiffness calculation using an accumulated integral potential energy method and dynamic analysis of helical gears. Mech. Mach. Theory 92, 447–463 (2015)

Ren, J.J., Liu, Y.C., Wang, N.: Sensorless control of ship propulsion interior permanent magnet synchronous motor based on a new sliding mode observer. ISA T. 54, 15–26 (2015)

Evans, I.: Lateral spacing of point-attack picks. Int. J. Min. Eng. 22, 7–10 (1984)

Evans, I.: A theory of the cutting force for point-attack picks. Int. J. Rock Mech. Min. 2, 63–71 (1984)

Li, C.X.: Shearer. China Coal Industry Publishing House, Beijing (1998)

Ran, L., Xiang, D., Kirtley, J.L.: Analysis of electromechanical interactions in a flywheel system with a doubly fed induction machine. IEEE T. Ind. Appl. 47(3), 1498–1506 (2011)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 51775543), the Key Research and Development Project of Xuzhou (Grant No. KC17014) and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The mass matrix and total stiffness coefficient matrix of gear system:

In some important simulation parameters, the gear meshing stiffness is the average meshing stiffness in the table:

Symbol | Value | Unit | Symbol | Value | Unit |

|---|---|---|---|---|---|

Kpω | 20 | C34 | 2.82e4 | N·s/m·rad | |

Kiω | 50 | C56 | 4.26e4 | N·s/m·rad | |

Kpq | 15 | C67 | 5.44e4 | N·s/m·rad | |

Kiq | 20.75 | C78 | 6.39e4 | N·s/m·rad | |

Ka | 1.10e6 | N/m·rad | m1 | 6.51 | kg |

Kb | 2.34e7 | N/m·rad | m2 | 56.2 | kg |

Kc | 2.85e7 | N/m·rad | m3 | 13.02 | kg |

Kd | 1.79e8 | N/m·rad | m4 | 87.26 | kg |

Ca | 4.43e2 | N·s/m·rad | m5 | 27.74 | kg |

Cb | 1.73e3 | N·s/m·rad | m6/m7 | 60.50 | kg |

Cc | 2.72e3 | N·s/m·rad | m8 | 131.38 | kg |

Cd | 5.64e3 | N/m·rad | J1 | 0.024 | kg m2 |

K12 | 2.78e9 | N/m·rad | J2 | 0.82 | kg m2 |

K34 | 2.87e9 | N/m·rad | J3 | 0.089 | kg m2 |

K56 | 3.68e9 | N/m·rad | J4 | 2.034 | kg m2 |

K67 | 4.02e9 | N/m·rad | J5 | 0.26 | kg m2 |

K78 | 4.18e9 | N/m·rad | J6/J7 | 1.18 | kg m2 |

C12 | 2.02e4 | N·s/m·rad | J8 | 3.26 | kg m2 |

Rights and permissions

About this article

Cite this article

Jiang, S., Li, W., Wang, Y. et al. Study on electromechanical coupling torsional resonance characteristics of gear system driven by PMSM: a case on shearer semi-direct drive cutting transmission system. Nonlinear Dyn 104, 1205–1225 (2021). https://doi.org/10.1007/s11071-021-06364-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-021-06364-9