Abstract

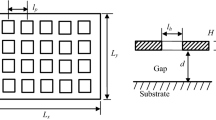

Squeezed air film between two closely spaced vibrating microstructures is the important source of energy dissipation and has profound effects on the dynamics of microelectromechanical systems (MEMS). Perforations in the design are one of the methods to model these damping effects. The literature reveals that the analytical modeling of squeeze film damping of perforated circular microplates is less explored; however, these microplates are also an imperative part of the numerous MEMS devices. Here, we derive an analytical model of transverse and rocking motions of a perforated circular microplate. A modified Reynolds equation that incorporates compressibility and rarefaction effects is utilized in the analysis. Pressure distribution under the vibrating microplate is derived by using Green’s function and also derived by finite element method (FEM) to visualize the pressure distribution under perforated and non-perforated areas of the microplate. The analytical damping results are validated with previous renowned analytical models and also with the FEM results. The outcomes confirm the potential of the present analytical model to accurately predict the squeeze film damping parameters.

Similar content being viewed by others

References

Abtahi, M., Vossoughi, G., Meghdari, A.: Effects of the van der waals force, squeeze-film damping, and contact bounce on the dynamics of electrostatic microcantilevers before and after pull-in. Nonlinear Dyn. (2014). doi:10.1007/s11071-014-1275-7

Liu, C.C., Liu, C.H.: Analysis of nonlinear dynamic behavior of electrically actuated micro-beam with piezoelectric layers and squeeze-film damping effect. Nonlinear Dyn. (2014). doi:10.1007/s11071-014-1384-3

Blech, J.: On isothermal squeeze films. J. Lubr. Technol. (1995). doi:10.1115/1.3254692

Darling, R.B., Hivick, C., Xu, J.: Compact analytical modeling of squeeze film damping with arbitrary venting conditions using a greens function approach. Sensor Actuat. A-Phys. (1998). doi:10.1016/S0924-4247(98)00109-5

Nayfeh, A.H., Younis, M.I.: A new approach to the modeling and simulation of flexible microstructures under the effect of squeeze-film damping. J. Micromech. Microeng. (2004). doi:10.1088/0960-1317/14/2/0024

Nayfeh, A.H., Younis, M.I., Abdel-Rahman, E.M.: Reduced-order models for MEMS applications. Nonlinear Dyn. (2005). doi:10.1007/s11071-005-2809-9

Bao, M., Yang, H., Sun, Y., French, P.J.: Modified reynolds equation and analytical analysis of squeeze-film air damping of perforated structures. J. Micromech. Microeng. (2003). doi:10.1088/0960-1317/13/6/301

Pandey, A.K., Pratap, R., Chau, F.S.: Analytical solution of the modified reynolds equation for squeeze film damping in perforated MEMS structures. Sensor Actuat. A-Phys. (2007). doi:10.1016/j.sna.2006.09.006

Li, P., Yuming, F.: An analytical model for squeeze-film damping of perforated torsional microplates resonators. Sensors-Basel (2015). doi:10.3390/s150407388

Pratap, R., Mohite, S., Pandey, A.K.: Squeeze film effects in MEMS devices. J. Indian Inst. Sci. 87, 75–94 (2007)

Skvor, Z.: On acoustical resistance due to viscous losses in the air gap of electrostatic transducers. Acustica 19, 295–299 (1967)

Homentcovschi, D., Miles, R.N.: Modelling of viscous damping of perforated planar micromechanical structures, applications in acoustics. J. Acoust. Soc. Am. (2004). doi:10.1121/1.1798331

Homentcovschi, D., Miles, R.N.: Viscous microstructural dampers with aligned holes: Design procedure including the edge correction. J. Acoust. Soc. Am. (2007). doi:10.1121/1.2756169

Kwok, P., Weinberg, M., Breuer, K.: Fluid effects in vibrating micromachined structures. J. Microelectromech. Syst. (2005). doi:10.1109/JMEMS.2005.845425

Feng, C., Zhao, Y.P., Liu, D.Q.: Squeeze-film effects in MEMS devices with perforated plates for small amplitude vibration. Microsyst. Technol. (2006). doi:10.1007/s00542-006-0285-x

Mohite, S.S., Kesari, H., Sonti, V.R., Pratap, R.: Analytical solutions for the stiffness and damping coefficients of squeeze films in MEMS devices with perforated back plates. J. Micromech. Microeng. (2005). doi:10.1088/0960-1317/15/11/013

Mohite, S., Sonti, V., Pratap, R.: A compact squeeze-film model including inertia, compressibility, and rarefaction effects for perforated 3-d MEMS structures. J. Microelectromech. Syst. (2008). doi:10.1109/JMEMS.2008.921675

Bao, M., Yang, H.: Squeeze film air damping in MEMS. Sensor Actuat. A-Phys. (2007). doi:10.1016/j.sna.2007.01.008

Li, P., Fang, Y., Xu, F.: Analytical modeling of squeeze-film damping for perforated circular microplates. J. Sound Vib. (2014). doi:10.1016/j.jsv.2013.12.028

Pandey, A.K., Pratap, R.: A comparative study of analytical squeeze film damping models in rigid rectangular perforated MEMS structures with experimental results. Microfluid. Nanofluid. (2008). doi:10.1007/s10404-007-0165-4

Veijola, T., Rback, P.: Methods for solving gas damping problems in perforated microstructures using a 2D finite-element solver. Sensors-Basel (2007). doi:10.3390/s7071069

Miles, R.N., Robert, D., Hoy, R.R.: Mechanically Coupled Ears for Directional Hearing in the Parasitoid Fly Ormia ochracea. J. Acoust. Soc. Am. 98, 3059–3070 (1995)

Touse, M., Sinibaldi, J., Simsek, K., Catterlin, J., Harrison, S., Karunasiri, G.: Fabrication of a microelectromechanical directional sound sensor with electronic readout using comb fingers. Appl. Phys. Lett. (2010). doi:10.1063/1.3418640

Knoernschild, C., Kim, T., Maunz, P., Crain, S.G., Kim, J.: Stable optical phase modulation with micromirrors. Opt. Express (2012). doi:10.1364/OE.20.003261

Xia, C., Qiao, D., Zeng, Q., Yuan, W.: The squeeze-film air damping of circular and elliptical micro-torsion mirrors. Microfluid. Nanofluid. (2015). doi:10.1007/s10404-015-1585-1

Ahmad, B., Pratap, R.: Analytical evaluation of squeeze film forces in a CMUT with sealed air-filled cavity. IEEE Sens. J. (2011). doi:10.1109/JSEN.2011.2119397

Pasquale, G., Veijola, T.: Comparative numerical study of FEM methods solving gas damping in perforated MEMS devices. Microfluid. Nanofluid. (2008). doi:10.1007/s10404-008-0264-x

Acknowledgments

This work is supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (Grant Number: 2013R1A1A2007684).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ishfaque, A., Kim, B. Analytical solution for squeeze film damping of MEMS perforated circular plates using Green’s function. Nonlinear Dyn 87, 1603–1616 (2017). https://doi.org/10.1007/s11071-016-3136-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-016-3136-z