Abstract

Understanding the interaction between complex geophysical flows and barriers remains a critical challenge for protecting infrastructure in mountainous regions. The scientific challenge lies in understanding how grain stresses in complex geophysical flows become manifested in the dynamic response of a rigid barrier. A series of physical flume tests were conducted to investigate the influence of varying the particle diameter of mono-dispersed flows on the impact kinematics of a model rigid barrier. Particle sizes of 3, 10, 23 and 38 mm were investigated. Physical tests results were then used to calibrate a discrete element model for carrying out numerical back-analyses. Results reveal that aside from considering bulk characteristics of the flow, such as the average velocity and bulk density, the impact load strongly depends on the particle size. The particle size influences the degree of grain inertial stresses which become manifested as sharp impulses in the dynamic response of a rigid barrier. Impact models that only consider a single impulse using the equation of elastic collision warrant caution as a cluster of coarse grains induce numerous impulses that can exceed current design recommendations by several orders of magnitude. Although these impulses are transient, they may induce local strucutral damage. Furthermore, the equation of elastic collision should be adopted when the normalized particle size with the flow depth, δ/h, is larger than 0.9 for Froude numbers less than 3.5.

Similar content being viewed by others

References

Armanini A, Larcher M, Odorizzi M (2011) Dynamic impact of a debris flow front against a vertical wall. In: Proceedings of 5th international conference on debris-flow hazards “mitigation, mechanics, prediction and assessment”, Padua, Italy

Ashwood W, Hungr O (2016) Estimating the total resisting force in a flexible barrier impacted by a granular avalanche using physical and numerical modeling. Can Geotech J. https://doi.org/10.1139/cgj-2015-0481

ASTM (2011) Standard test method for direct shear test of soils under consolidated drained conditions. D3080/D3080 M. West Conshohocken, PA

Bardou E, Ancey C, Bonnard C, Vulliet L (2003) Classification of debris-flow deposits for hazard assessment in alpine areas. In 3th international conference on debris-flow hazards mitigation: mechanics, prediction, and assessment, Millpress

Berger C, McArdell BW, Schlunegger F (2011) Sediment transfer patterns at the Illgraben catchment, Switzerland: implications for the time scales of debris flow activities. Geomorphology 125(3):421–432

Brighenti R, Segalini A, Ferrero AM (2013) Debris flow hazard mitigation: a simplified analytical model for the design of flexible barriers. Comput Geotech 54:1–15

Brunet M, Moretti L, Le Friant A, Mangeney A, Nieto EDF, Bouchut F (2017) Numerical simulation of the 30–45 ka debris avalanche flow of Montagne Pelée volcano, Martinique: from volcano flank collapse to submarine emplacement. Nat Hazards 87(2):1189–1222

Bugnion L, McArdell B, Bartelt P, Wendeler C (2012) Measurements of hillslope debris flow impact pressure on obstacles. Landslides 9(2):179–187

Chiou MC (2005) Modelling of dry granular avalanches past different obstructs: numerical simulations and laboratory analyses. Ph.D. dissertation, Technical University Darmstadt

Choi CE (2013) Flume and discrete element investigation of granular flow mechanisms and interaction with baffles. Ph.D. thesis. Hong Kong University of Science and Technology, Hong Kong, China

Choi CE, Law RPH (2015) Mechanisms and performance of landslide debris flow baffles. HKIE T 22(4):235–246

Choi CE, Ng CWW, Song D, Kwan JSH, Shiu HYK, Ho KKS, Koo RCH (2014a) Flume investigation of landslide debris baffles. Can Geotech J 51(5):533–540

Choi CE, Ng CWW, Song D, Law RPH, Kwan JSH, Ho KKS (2014b) A computational investigation of baffle configuration on the impedance of channelized debris flow. Can Geotech J 52(2):182–197

Choi CE, Au-Yeung S, Ng CWW (2015a) Flume investigation of landslide granular debris and water runup mechanisms. Géotech Lett 5(1):28–32

Choi CE, Ng CWW, Au-Yeung SCH, Goodwin G (2015b) Froude scaling of landslide debris in flume modelling. Landslides 12(6):1197–1206

Choi CE, Goodwin GR, Ng CWW, Cheung DKH, Kwan JSH, Pun WK (2016) Coarse granular flow interaction with slit structures. Géotech Lett 6(4):267–274

Chu T, Hill G, McClung DM, Ngun R, Sherkat R (1995) Experiments on granular flows to predict avalanche runup. Can Geotech J 32(2):285–295

Cui Y, Nouri A, Chan D, Rahmati E (2016) A new approach to DEM simulation of sand production. J Petrol Sci Eng 147:56–67

Cui Y, Chan D, Nouri A (2017a) Discontinuum modeling of solid deformation pore-water diffusion coupling. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000903

Cui YF, Chan D, Nouri A (2017b) Coupling of solid deformation and pore pressure for undrained deformation—a discrete element method approach. Int J Numer Anal Meth Geomech 41(18):1943–1961

DeBruyn J (2011) Viewpoint: unifying liquid and granular flow. Physics 4:86

DeNatale JS, Iverson RM, Major JJ, LaHusen RG, Fiegel GL, Duffy JD (1999) Experimental testing of flexible barriers for containment of debris flows. US Department of the Interior, US Geological Survey

Faug T, Lachamp P, Naaim M (2002) Experimental investigation on steady granular flows interacting with an obstacle down an inclined channel: study of the deadzones upstream from the obstacle application to interaction between dense snow avalanches and defence structures. Nat Hazards Earth Syst Sci 2:187–191

Feng Z, Lo C, Lin Q (2017) The characteristics of the seismic signals induced by landslides using a coupling of discrete element and finite difference methods. Landslides 14(2):661–674

Fleischmann JA, Plesha ME, Drugan WJ (2011) Quantitative comparison of two-dimensional and three-dimensional discrete-element simulations of nominally two-dimensional shear flow. Int J Geomech 13(3):205–212

Forterre Y, Pouliquen O (2011) Granular flows. Glasses and Grains. Springer, Basel, pp 77–109

Gray JMNT, Tai YC, Noelle S (2003) Shock waves, dead zones and particle-free regions in rapid granular free-surface flows. J Fluid Mech 491:161–181

Hauksson S, Pagliardi M, Barbolini M, Jóhannesson T (2007) Laboratory measurements of impact force of supercritical granular flow against mast-like obstacles. Cold Reg Sci Technol 49(1):54–63

Hu K, Wei F, Li Y (2011) Real-time measurement and preliminary analysis of debris-flow impact force at Jiangjia Ravine, China. Earth Surf Process Landf 36(9):1268–1278

Hungr O (1995) A model for the runout analysis of rapid flow slides, debris flows, and avalanches. Can Geotech J 32:610–623

Hungr O (2008) Simplified models of spreading flow of dry granular material. Can Geotech J 45(8):1156–1168

Hungr O, Morgan GC, Kellerhals R (1984) Quantitative analysis of debris torrent hazards for design of remedial measures. Can Geotech J 21(4):663–677

Hürlimann M, Rickenmann D, Graf C (2003) Field and monitoring data of debris-flow events in the Swiss Alps. Can Geotech J 40(1):161–175

Itasca, Consulting Group Inc 2014. PFC particle flow code. Ver. 5.0 Manual. Itasca, Minneapolis

Iverson RM (1997) The physics of debris flows. Rev Geophys 35(3):245–296

Iverson RM (2015) Scaling and design of landslide and debris-flow experiments. Geomorphology 244:9–20

Iverson RM, George DL (2014) A depth-averaged debris-flow model that includes the effects of evolving dilatancy. I. Physical basis. Proc R Soc 470(2170):20130819

Jakob M, Hungr O (2005) Debris-flow hazards and related phenomena. Springer, Berlin

Jiang YJ, Towhata I (2013) Experimental study of dry granular flow and impact behavior against a rigid retaining wall. Rock Mech Rock Eng 46:713–729

Jiang YJ, Zhao Y, Towhata I, Liu DX (2015) Influence of particle characteristics on impact event of dry granular flow. Powder Technol 270:53–67

Kang C (2016) Modelling entrainment in debris flow analysis for dry granular material. Ph.d. thesis. University of Alberta, Alberta, Canada

Kanungo DP, Pain A, Sharma S (2013) Finite element modeling approach to assess the stability of debris and rock slopes: a case study from the Indian Himalayas. Nat Hazards 69(1):1–24

Koo RCH, Kwan JSH, Ng CWW, Lam C, Choi CE, Song D, Pun WK (2016) Velocity attenuation of debris flows and a new momentum-based load model for rigid barriers. Landslides 14(2):617–629

Kwan JSH (2012) Supplementary technical guidance on design of rigid debris-resisting barriers. Technical note no. TN 2/2012. Geotechnical Engineering Office, Civil Engineering and Development Department, The HKSAR Government

Kwan JHS, Koo RCH, Ng CWW (2015) Landslide mobility analysis for design of multiple debris-resisting barriers. Can Geotech J 52(9):1345–1359

Law RPH, Choi CE, Ng CWW (2015) Discrete element investigation of the influence of debris flow baffles on rigid barrier impact. Can Geotech J 53(2):179–185

Leonardi A, Wittel FK, Mendoza M, Vetter R, Herrmann HJ (2014) Particle-fluid-structure interaction for debris flow impact on flexible barriers. Comput-Aid Civil Infrastruct Eng 31(5):323–333

Leroy B (1985) Collision between two balls accompanied by deformation: a qualitative approach to Hertz’s theory. Am J Phys 53(4):346–349

Li X, He S, Luo Y, Wu Y (2010) Discrete element modeling of debris avalanche impact on retaining walls. J Mt Sci 7(3):276–281

Lin DG, Hsu SY, Chang KT (2009) Numerical simulations of flow motion and deposition characteristics of granular debris flows. Nat Hazards 50(3):623–650

Liu Z, Koyi HA (2013) Kinematics and internal deformation of granular slopes: insights from discrete element modelling. Landslides 10(2):139–160

Mancarella D, Hungr O (2010) Analysis of run-up of granular avalanches against steep, adverse slopes and protective barriers. Can Geotech J 47(8):827–841

McArdell BW, Bartelt P, Kowalski J (2007) Field observations of basal forces and fluid pore pressure in a debris flow. Geophys Res Lett 34(L07406):1–4

Moriguchi S, Borja RI, Yashima A, Sawada K (2009) Estimating the impact force generated by granular flow on a rigid obstruction. Acta Geotech 4(1):57–71

Ng CWW, Choi CE, Song D, Kwan JSH, Shiu HYK, Ho KKS, Koo RCH (2014) Physical modelling of baffles influence on landslide debris mobility. Landslides 12(1):1–18

Ng CWW, Choi CE, Su AY, Kwan JSH, Lam C (2016) Large-scale successive impacts on a rigid barrier shielded by gabions. Can Geotech J 53(10):1688–1999

Ng CWW, Song D, Choi CE, Kwan JSH, Shiu HYK, Koo RCH (2017a) Impact mechanisms of granular and viscous flows on rigid and flexible barriers. Can Geotech J 54(2):188–206

Ng CWW, Choi CE, Goodwin RG, Cheung WW (2017b) Interaction between dry granular flow and deflectors. Landslides 14(1):1–11

Ng CWW, Choi CE, Liu LHD, Wang Y, Song D, Yang N (2017c) Influence of particle size on the mechanism of dry granular run-up on a rigid barrier. Géotech Lett 7:1–11

Podczeck F, Mia Y (1996) The influence of particle size and shape on the angle of internal friction and the flow factor of unlubricated and lubricated powders. Int J Pharm 144(2):187–194

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Proske D, Suda J, Hübl J (2011) Debris flow impact estimation for breakers. Georisk 5(2):143–155

Pudasaini SP, Hutter K (2007) Avalanche dynamics. Springer, Berlin, p 602

Salciarini D, Tamagnini C, Conversini P (2010) Discrete element modeling of debris-avalanche impact on earthfill barriers. Phys Chem Earth 35(3):172–181

Savage SB (1984) The mechanics of rapid granular flows. Adv Appl Mech 24:289–366

Savage SB, Hutter K (1989) The motion of a finite mass of granular material down a rough incline. J Fluid Mech 199:177–215

Song D, Ng CWW, Choi C, Zhou GG, Kwan JSH, Koo RCH (2017) Influence of debris flow solid fraction on rigid barrier impact. Can Geotech J. https://doi.org/10.1139/cgj-2016-0502

Sovilla B, Schaer M, Kern M, Bartelt P (2008) Impact pressures and flow regimes in dense snow avalanches observed at the Vallée de la Sionne test site. J Geophys Res Earth Surf 113(F01010):1–14

Speerli J, Hersperger R, Wendler C, Roth A (2010) Physical modeling of debris flow over flexible ring barriers. In: Proceedings of 7th international conference of physical modelling in geotechnics, springman. Laue and Seward, Taylor and Francis Group, London

SWCB (2005) Manual of soil and water conservation. Soil and Water Conservation Bureau, Taiwan, 692 (in Chinese)

Tan SB, Newton JM (1990) Powder flow ability as an indication of capsule filling performance. Int J Pharm 61(1–2):145–155

Tang Y, Chan D, Zhu DZ (2017) A coupled discrete element model for the simulation of soil and water flow through an orifice. Int J Numer Anal Meth Geomech. https://doi.org/10.1002/nag.2677

Teufelsbauer H, Wang Y, Chiou MC, Wu W (2009) Flow–obstacle interaction in rapid granular avalanches: DEM simulation and comparison with experiment. Granular Matter 11(4):209–220

Teufelsbauer H, Wang Y, Pudasaini SP, Borja RI, Wu W (2011) DEM simulation of impact force exerted by granular flow on rigid structures. Acta Geotech 6:119–133

Valentino R, Barla G, Monstrasio L (2008) Experimental analysis and micromechanical modelling of dry granular flow and impacts in laboratory flume tests. Rock Mech Rock Eng 41(1):153–177

VanDine DF (1996) Debris flow control structures for forest engineering. Ministry of Forests, British Columbia, p 68

White DJ, Take WA, Bolton MD (2003) Soil deformation measurement using particle image velocimetry (PIV) and photogrammetry. Géotechnique 53(7):619–631

Yuan R, Tang C, Deng Q (2015a) Effect of the acceleration component normal to the sliding surface on earthquake-induced landslide triggering. Landslides 12(2):335–344

Yuan R, Tang C, Deng Q (2015b) Effect of the acceleration component normal to the sliding surface on earthquake-induced landslide triggering. Landslides 12:335–344

Zanuttigh B, Lamberti A (2006) Experimental analysis of the impact of dry avalanches on structures and implication for debris flows. J Hydraul Res 47(4):381–383

Zhang S, Hungr O, Slaymaker O (1996) The calculation of impact force of boulders in debris flow. Debris flow observation and research. Science Press, Beijing, pp 67–72

Zhou GGD, Sun QC (2013) Three-dimensional numerical study on flow regimes of dry granular flows by DEM. Powder Technol 239:115–127

Zhou JW, Cui P, Fang H (2013) Dynamic process analysis for the formation of Yangjiagou landslide-dammed lake triggered by the Whenchuan earthquake, China. Landslides 10(3):331–342

Zhou JW, Huang KX, Shi C, Hao MH, Guo CX (2015) Discrete element modeling of the mass movement and loose material supplying the gully process of a debris avalanche in the Bayi Gully, Southwest China. J Asian Earth Sci 99:95–111

Acknowledgements

The authors are grateful for financial support from the theme-based Research Grant T22-603/15-N and the General Research Fund 16209717 provided by the Research Grants Council of the Government of Hong Kong SAR, China. The authors would like to gratefully acknowledge the support of the HKUST Jockey Club Institute for Advanced Study. The authors would also like to thank the financial support from the Natural Science Foundation of China (E090705).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Comparison of numerical 2D and 3D analysis

1.1 Input parameters and modelling procedures

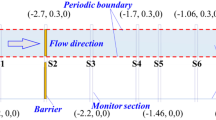

The 3D numerical model is geometrically similar to the physical model tests (Fig. 8). The storage container, channel walls and barrier are modelled as planar and rigid elements. A linear contact model was adopted, consisting of a linear spring dashpot. Impact kinematics and dynamics were measured along the height of the barrier. The input parameters and modelling procedures are reminiscent to those used in the 2D simulations. Each simulation included the generation of a target mass of 20 kg. The total number of elements N is calculated as follows:

where \(M_{\text{T}}\) is the total weight of sample which is equal to 20 kg, \(M_{\text{p}}\) is the mass of a single particle in 3D case, and can be calculated from Eq. 4:

where \(\rho\) and \(r\) are the density and radius of each element, respectively.

After the generation of particles, a gravitational acceleration of 9.81 m/s2 was applied to the computational domain and elements were allowed to free fall in the storage container until the ratio of average unbalanced force to the average contact forces converged was less than 1% difference (Cui et al. 2016). The storage container gate was then deleted to simulate dam break initiation mechanism to release the discrete elements downslope into the rigid barrier.

1.2 Interpretation and discussion

Results show that for 3D simulation, the impact load exhibit a disparity of about 20% less compared to 2D simulation. The difference is attributed predominantly to side wall effects, which is the most apparent from observing the geometry of the flow fronts in both the 2D and 3D simulations. Furthermore, the 2D simulations exhibit several distinct impulses after the initial peak impulse. By contrast, the 3D simulations did not have such observation. This is because of the enhanced degree of freedom for the 3D simulations. The additional degree of freedom enhances the attenuation of flow energy in the direction perpendicular to the flow.

To further elucidate the impact mechanism pertaining to the 2D simulations, the computed flow kinematics between the first and second impacts (computational time from 0.719 s to 0.794 s) are shown in Fig. 9a–f. The arrow of each particle indicates a velocity vector. From the computed results, it is evident that two particles in particular (Particles No. 1 and No. 2) impact the rigid barrier almost simultaneously (Fig. 9a, b). After the first impact, Particles No. 1 and No. 2 rebound and collide with the incoming particles, specifically Particle No. 3 (Fig. 9c, d). After this collision, Particle No. 1 bounces back towards the barrier and induces a second impact (Fig. 9e, f).

The observed dynamics lead to two distinct impact forces as shown in Fig. 10. By contrast, this phenomenon is not as evident in the 3D simulations because a larger number of particles and greater momentum transfer in the lateral direction lead to lower impact loads for the 3D case compared to the 2D case.

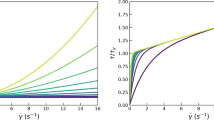

Appendix 2: Calibration of frictional parameter

Before the experimental flume test, the direct shear test is carried out for glass spheres with 3 mm diameter, following the standard ASTM standard (ASTM 2011). The samples were filled in a standard shear box measuring 50.8 \(\times\) 50.8 \(\times\) 21.5 mm (width \(\times\) length \(\times\) height), after which a constant compaction effort was applied to the samples, which brought them to a dense state and similar densities. The samples were tested at 45, 90 and 180 kPa normal stresses in a strain-controlled mode at a shear rate of 0.02 mm/min. Figure 11 shows the frictional angle for 3-mm-diameter glass sphere is 20 degree, which corresponds to the inter-element frictional coefficient of 0.36.

The interface-element frictional coefficient of the glass sphere was measured in Choi et al. (2016) by means of tilting tests referring to Pudasaini and Hutter (2007), Mancarella and Hungr (2010), Jiang and Towhata (2013). A cylindrical container of 200 mm diameter filled with granular material to a height of 100 mm was placed on the channel. The channel was inclined until the container began to slide. At this moment, the angle of the channel was recorded as the interface friction angle. The recorded angle 22 degree is then converted to interface-element frictional coefficient as 0.4 in DEM calculations.

Rights and permissions

About this article

Cite this article

Cui, Y., Choi, C.E., Liu, L.H.D. et al. Effects of particle size of mono-disperse granular flows impacting a rigid barrier. Nat Hazards 91, 1179–1201 (2018). https://doi.org/10.1007/s11069-018-3185-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-018-3185-3