Abstract

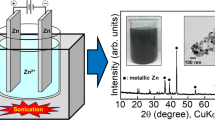

The present paper describes the preparation of metallic aluminum (Al) nanoparticles in an aqueous solution. An aqueous colloidal solution containing metallic Al nanoparticles was prepared by electrolyzing an Al salt aqueous solution using two metallic Al plate electrodes. Simultaneous electrolysis and sonication was necessary for the successful synthesis of metallic Al particles with a cubic crystal structure. Metallic Al particles were mainly produced on the cathode. Electrolysis under sonication was performed under various conditions. The morphology of the particles strongly depended on the temperature, electrolysis time, and sonication frequency, which could be mainly explained by changes in particle collision frequency and dissolution, particle collision frequency, and attenuation in the medium and/or cavitation stability, respectively. Metallic Al particles could be prepared using a stainless-steel plate as the cathode. Under the appropriate conditions, metallic Al particles with particle sizes of ca. 75–130 nm could be synthesized.

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Sarafraz MM, Christo FC, Tran NN, Fulcheri L, Hessel V (2022) Thermal plasma-aided chemical looping carbon dioxide dissociation for fuel production from aluminium particles. Energy Convers Manag 257:115413. https://doi.org/10.1016/j.enconman.2022.115413

Etminanbakhsh M, Allahkaram SR (2023) Reaction of aluminum particles with superheated steam to generate hydrogen gas as a readily usable clean fuel. Fuel 332:126011. https://doi.org/10.1016/j.fuel.2022.126011

Liu W, Zhang H, Shao Y, Zhang H, Zhu J (2020) Preparation of aluminium metallic pigmented powder coatings with high color stability using a novel method: microwave bonding. Prog Org Coat 147:105787. https://doi.org/10.1016/j.porgcoat.2020.105787

Gromov AA, Förter-Barth U, Teipel U (2006) Aluminum nanopowders produced by electrical explosion of wires and passivated by non-inert coatings: characterisation and reactivity, with air and water. Powder Technol 164:111–115. https://doi.org/10.1016/j.powtec.2006.03.003

Antony JK, Vasa NJ, Chakravarthy SR, Sarathi R (2010) Understanding the mechanism of nano-aluminum particle formation by wire explosion process using optical emission technique. J Quant Spectrosc Radiat Transf 111:2509–2516. https://doi.org/10.1016/j.jqsrt.2010.07.011

Lerner MI, Glazkova EA, Lozhkomoev AS, Svarovskaya NV, Bakina OV, Pervikov AV, Psakhie SG (2016) Synthesis of Al nanoparticles and Al/AlN composite nanoparticles by electrical explosion of aluminum wires in argon and nitrogen. Powder Technol 295:307–314. https://doi.org/10.1016/j.powtec.2016.04.005

Mathe VL, Varma V, Raut S, Nandi AK, Pant A, Prasanth H, Pandey RK, Bhoraskar SV, Das AK (2016) Enhanced active aluminum content and thermal behaviour of nano-aluminum particles passivated during synthesis using thermal plasma route. Appl Surf Sci 368:16–26. https://doi.org/10.1016/j.apsusc.2016.01.246

Abdelkader EM, Jelliss PA, Buckner SW (2016) Main group nanoparticle synthesis using electrical explosion of wires, Nano-Struct. Nano-Objects 7:23–31. https://doi.org/10.1016/j.nanoso.2016.05.001

Karthik PS, Chandrasekhar B, Chakravarty D, PVV S, Chakravadhanula VSK, Rao TN (2018) Propellant grade ultrafine aluminum powder by RF induction plasma. Adv Powder Technol 29:804–812. https://doi.org/10.1016/j.apt.2017.12.024

García-Caballero V, Mohammed-Ibrahim HK, Giner-Casares JJ, Cano M (2022) Influence of the synthesis route on the electrocatalytic performance for ORR of citrate-stabilized gold nanoparticles. Electrochem Commun 142:107364. https://doi.org/10.1016/j.elecom.2022.107364

Khan MAR, Mamun MSA, Ara MH (2021) Review on platinum nanoparticles: synthesis, characterization, and applications. Microchem J 171:106840. https://doi.org/10.1016/j.microc.2021.106840

Chaurasia PK, Bharati SL, Yadava S (2022) Nano-reduction of gold and silver ions: a perspective on the fate of microbial laccases as potential biocatalysts in the synthesis of metals (gold and silver) nano-particles. Curr Res Microb Sci 3:100098. https://doi.org/10.1016/j.crmicr.2021.100098

Nie H, Schoenitz M, Dreizin EL (2012) Calorimetric investigation of the aluminum-water reaction. Int J Hydrog Energy 37:11035–11045. https://doi.org/10.1016/j.ijhydene.2012.05.012

Haber JA, Buhro WE (1998) Kinetic Instability of nanocrystalline aluminum prepared by chemical synthesis; facile room-temperature grain growth. J Am Chem Soc 120:10847–10855. https://doi.org/10.1021/ja981972y

Cui Y, Zhao S, Tao D, Liang Z, Huang D, Xu Z (2014) Synthesis of size-controlled and discrete core-shell aluminum nanoparticles with a wet chemical process. Mater Lett 121:54–57. https://doi.org/10.1016/j.matlet.2014.01.122

Riegsinger S, Popescu R, Gerthsen D, Feldmann C (2022) Room-temperature liquid-phase synthesis of aluminium nanoparticles. Chem Commun 58:499. https://doi.org/10.1039/d2cc01846b

Meziani MJ, Bunker CE, Lu F, Li H, Wang W, Guliants EA, Quinn RA, Sun YP (2009) Formation and properties of stabilized aluminum nanoparticles. ACS Appl Mater Interfaces 1:703–709. https://doi.org/10.1021/am800209m

Lee HM, Choi SY, Yun JY (2011) Preparation of aluminum–organic nanocomposite materials via wet chemical process. Adv Powder Technol 22:608–612. https://doi.org/10.1016/j.apt.2010.09.003

Clark BD, DeSantis CJ, Wu G, Renard D, McClain MJ, Bursi L, Tsai AL, Nordlander P, Halas NJ (2019) Ligand-dependent colloidal stability controls the growth of aluminum nanocrystals. J Am Chem Soc 141:1716–1724. https://doi.org/10.1021/jacs.8b12255

Jacobson CR, Solti D, Renard D, Yuan L, Lou M, Halas NJ (2020) Shining light on aluminum nanoparticle synthesis. Acc Chem Res 53:2020–2030. https://doi.org/10.1021/acs.accounts.0c00419

Li M, Gao B, Liu C, Chen W, Shi Z, Hu X, Wang Z (2015) Electrodeposition of aluminum from AlCl3/acetamide eutectic solvent. Electrochim Acta 180:811–814. https://doi.org/10.1016/j.electacta.2015.09.008

Ismail AS (2016) Nano-sized aluminum coatings from aryl-substituted imidazolium cation based ionic liquid. Egypt J Pet 25:525–530. https://doi.org/10.1016/j.ejpe.2015.11.007

Elterman VA, Shevelin PY, Yolshina LA, Borozdin AV (2021) Electrodeposition of aluminium from the chloroaluminate ionic liquid 1-ethyl-3-methylimidazolium chloride. Electrochim Acta 389:138715. https://doi.org/10.1016/j.electacta.2021.138715

Bhujbal AV, Venkatesan KA, Bhanage BM (2021) Electrochemical deposition of nanocrystalline aluminum from a protic ionic liquid on mild steel. J Mol Liq 326:115275. https://doi.org/10.1016/j.molliq.2021.115275

Cvetković VS, Vukićević NM, Jovićević N, Stevanović JS, Jovićević JN (2020) Aluminium electrodeposition under novel conditions from AlCl3-urea deep eutectic solvent at room temperature. Trans Nonferrous Metals Soc China 30:823–834. https://doi.org/10.1016/S1003-6326(20)65257-8

Yoshida A, Yamauchi N, Nakashima K, Watanabe K, Koda H, Kunigami H, Kunigami H, Kobayashi Y (2020) Synthesis of metallic zinc nanoparticles by electrolysis. Appl Nanosci 10:3457–3464. https://doi.org/10.1007/s13204-020-01524-6

Hosoya T, Yonezawa T, Yamauchi N, Nakashima K, Kobayashi Y (2021) Synthesis of metallic aluminum particles by electrolysis in aqueous solution. Micro Nano Syst Lett 9:14. https://doi.org/10.1186/s40486-021-00141-4

Shabana S, Sonawane SH, Ranganathan V, Pujjalwar PH, Pinjari DV, Bhanvase BA, Gogate PR, Ashokkumar M (2017) Improved synthesis of aluminium nanoparticles using ultrasound assisted approach and subsequent dispersion studies in di-octyl adipate. Ultrason Sonochem 36:59–69. https://doi.org/10.1016/j.ultsonch.2016.11.020

L’Haridon-Quaireau S, Laot M, Colas K, Kapusta B, Delpech S, Gosset D (2020) Effects of temperature and pH on uniform and pitting corrosion of aluminium alloy 6061-T6 and characterisation of the hydroxide layers. J Alloys Compd 833:155146. https://doi.org/10.1016/j.jallcom.2020.155146

Ryl J, Wysocka J, Cieslik M, Gerengi H, Ossowski T, Krakowiak S, Niedzialkowski P (2019) Understanding the origin of high corrosion inhibition efficiency of bee products towards aluminium alloys in alkaline environments. Electrochim Acta 304:263–274. https://doi.org/10.1016/j.electacta.2019.03.012

Zawrah MF, Wassel AR, Youness RA, Taha MA (2022) Recycling of aluminum dross and silica fume wastes for production of mullite-containing ceramics: powder preparation, sinterability and properties. Ceram Int 48:31661–31671. https://doi.org/10.1016/j.ceramint.2022.07.087

Zhang L, Wang S, Su X, Li X, Zou M (2022) Preparation and characterization of core-shell Al@PFHP with improving the combustion and ignition properties of aluminum powder. Particuology in press. https://doi.org/10.1016/j.partic.2022.08.008

Darowicki K, Orlikowski J, Arutunowa A, Jurczak W (2006) The effect of tensile stresses on aluminium passive layer durability. Electrochim Acta 51:6091–6096. https://doi.org/10.1016/j.electacta.2005.12.054

Luo L, Li Y, Sun X, Li J, Hu E, Liu Y, Tian Y, Yang XQ, Li Y, Lin WF, Kuang Y, Liu W, Sun X (2020) Synthesis and properties of stable sub-2-nm-thick aluminum nanosheets: oxygen passivation and two-photon luminescence. Chem 6:448–459. https://doi.org/10.1016/j.chempr.2019.11.004

Kroll R, Kearns P, Usman BJ, Zhou X, Engelberg DL (2023) A novel approach to determine cathodic passivation characteristics and semiconducting properties of pure aluminium 99.5 wt% and aluminium alloy 7075-T6 with an electrochemical pen electrode. Corros Sci 211:110898. https://doi.org/10.1016/j.corsci.2022.110898

Ziashahabia A, Poursalehi R (2015) The effects of surface oxidation and interparticle coupling on surface plasmon resonance properties of aluminum nanoparticles as a UV plasmonic material. Procedia Mater Sci 11:434–437. https://doi.org/10.1016/j.mspro.2015.11.030

Katyal J, Badoni V (2021) Localized surface plasmon resonance and field enhancement of Au, Ag, Al and Cu nanoparticles having isotropic and anisotropic nanostructure. Mater Today: Proc 44:5012–5017. https://doi.org/10.1016/j.matpr.2021.01.027

Ahmad AL, Idrus NF, Othman MR (2005) Preparation of perovskite alumina ceramic membrane using sol-gel method. J Membr Sci 262:129–137. https://doi.org/10.1016/j.memsci.2005.06.042

Tan H, Guo C (2011) Preparation of long alumina fibers by sol-gel method using malic acid. Trans Nonferrous Metals Soc China 21:1563–1567. https://doi.org/10.1016/S1003-6326(11)60897-2

Roque-Ruiz JH, Cabrera-Ontiveros EA, González-García G, Reyes-López SY (2016) Thermal degradation of aluminum formate sol-gel; synthesis of α-alumina and characterization by 1H, 13C and 27Al MAS NMR and XRD spectroscopy. Results Phys 6:1096–1102. https://doi.org/10.1016/j.rinp.2016.11.052

Niero DF, Montedo ORK, Bernardin AM (2022) Synthesis and characterization of nano α-alumina by an inorganic sol–gel method. Mater Sci Eng B 280:115690. https://doi.org/10.1016/j.mseb.2022.115690

He F, Li W, Pang T, Zhou L, Wang C, Liu H, Li M, He X (2022) Hydrothermal synthesis of boehmite nanorods from alumina sols. Ceram Int 48:18035–18047. https://doi.org/10.1016/j.ceramint.2022.02.212

Kaczmarek K, Hornowski T, Antal I, Rajnak M, Timko M, Józefczak A (2020) Sono-magnetic heating in tumor phantom. J Magn Magn Mater 500:166396. https://doi.org/10.1016/j.jmmm.2020.166396

Nalesso S, Varlet G, Bussemaker MJ, Sear RP, Hodnett M, Monteagudo-Oliván R, Sebastián V, Coronas J, Lee J (2021) Sonocrystallisation of ZIF-8 in water with high excess of ligand: effects of frequency, power and sonication time. Ultrason Sonochem 76:105616. https://doi.org/10.1016/j.ultsonch.2021.105616

Li J, Zhao HWK, Wang M, Chen D, Chen M (2020) Effect of anodizing temperature and organic acid addition on the structure and corrosion resistance of anodic aluminum oxide films. Thin Solid Films 713:138359. https://doi.org/10.1016/j.tsf.2020.138359

Chien YC, Weng HC (2021) Cost-effective technique to fabricate a tubular through-hole anodic aluminum oxide membrane using one-step anodization. Microelectron Eng 247:111589. https://doi.org/10.1016/j.mee.2021.111589

Terashima A, Iwai M, Kikuchi T (2022) Nanomorphological changes of anodic aluminum oxide fabricated by anodizing in various phosphate solutions over a wide pH range. Appl Surf Sci 605:154687. https://doi.org/10.1016/j.apsusc.2022.154687

Acknowledgements

We would like to thank Takehiro Yonezawa of the Innovation Center, Mitsubishi Materials Corporation, Japan, for facilitating the fruitful discussion on the present work.

Author information

Authors and Affiliations

Contributions

Takefumi Hosoya: methodology, investigation, formal analysis, writing—original draft. Shiori Sato: methodology, investigation. Yoshiki Ueno: methodology, investigation. Ayumi Takahashi: methodology, investigation. Noriko Yamauchi: investigation, writing—review and editing. Shohei Tada: writing—review and editing. Yoshio Kobayashi: conceptualization, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(PDF 169 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hosoya, T., Sato, S., Ueno, Y. et al. Electrolytic synthesis of metallic aluminum nanoparticles in aqueous solution. J Nanopart Res 25, 164 (2023). https://doi.org/10.1007/s11051-023-05814-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-023-05814-2