Abstract

We report the facile, one-step acetonitrile-mediated synthesis and self-assembly of β-AgVO3 nanowires into three-dimensional (3D) porous spongy-like hydrogel (~ 4 cm diameter) as cathode material for lithium ion battery of high performance and long-term stability. 3D structures made with superlong, very thin, and monoclinic β-AgVO3 nanowires exhibit high specific discharge capacities of 165 mAh g−1 in the first cycle and 100 mAh g−1 at the 50th cycle, with a cyclic capacity retention of 53% at a current density of 50 mA g−1. 3D structures are synthesized by reaction between ammonium vanadate and silver nitrate solution containing 5 mL of acetonitrile followed by a hydrothermal treatment at 200 °C for 12 h. Acetonitrile (used here for the first time in the silver vanadate synthesis) plays an important role in the self-assembly of the silver vanadate nanowires. A tentative growth mechanism for the 3D structure and lithium ions intercalation into β-AgVO3 nanowires has been discussed and described.

Similar content being viewed by others

Introduction

Mixed transition metal oxides especially oxides of vanadium have attracted a great scientific attention because of their unique physicochemical properties in a variety of useful industrial applications such as gas sensors, catalysts, electronic devices, lithium batteries, supercapacitors, clean energy, solar cells, etc. (Cao et al. 2005; Liu et al. 2005; Mai et al. 2010a, b; Liu et al. 2016; Xiong et al. 2015; Lu et al. 2016). Considered one of the most complex material among all the vanadium oxides-related compounds, silver vanadium oxides (SVOs), having a number of phases, depending on the synthesis methods, reaction conditions, and material stoichiometry are a matter of profound scientific and industrial research interest. Having different ratios of silver, vanadium, and oxygen, SVOs have been extensively investigated and resulted ingeniously different chemical, physical, sensing, electrochemical, optical, catalytic, magnetic, electrical properties, as well as applications for antibacterial material, surface-enhanced Raman scattering substrates, high temperature lubricating materials, and so on (Takeuchi et al. 2001; Whittingham 2004; Bao et al., 2007b, b; Feng et al. 2013; Zhou et al. 2011; Holtz et al. 2010; Das et al. 2012; Kittaka et al. 2000; Jang et al. 2014; Singh et al. 2010). Besides, SVOs are attracting many researcher’s attentions these days, since it possesses a variety of oxidation states, which makes it a potential cathode material to achieve high capacity and energy density, compared to other traditional cathode materials in lithium ion batteries. Apart from that, the superior ionic properties as well as the layered structures make it an ideal cathodic electrode for lithium ion batteries (Feng et al. 2013). Among all SVOs, β-AgVO3 has drawn much attention due to its stability, higher Ag/V ratio, and superior high-rate discharge capacity (Takeuchi and Piliero, 1987; Zhang et al. 2006; Song et al. 2009). Interestingly, the various properties of AgVO3 are highly dependent to the various synthesis strategies, hierarchical morphology, crystal structures, mixed phases, and surface properties of the product (Liu et al. 2006; Xie et al. 2005). Recently, many groups have synthesized various nanostructured AgVO3 to improve the cycling performance and rate capability of the AgVO3 material (Sharma et al. 2005; Shao et al. 2008). Various methods specially wet chemical and hydrothermal methods have been employed to grow long β-AgVO3 nanoribbons/nanowires/nanorods (Zhang et al. 2006; Song et al. 2009; Liu et al. 2006; Xie et al. 2005; Sharma et al. 2005; Shao et al. 2008). Pyridine-assisted solution approach was adopted by Song et al. (2009) to synthesize superlong β-AgVO3 nanowires and studied their electrochemical performance. Polyaniline-assisted triaxial nanowires of β-AgVO3 was synthesized by Mai et al. (2011a, b) by combining in situ chemical oxidative polymerization and the interfacial redox reaction between Ag+ and aniline. Liang et al. (2014) reported 3D AgVO3 nanowires composite aerogels with the help of two-dimensional graphene nanosheets. However, assembly of pure 1D silver vanadate nanowires into a flexible free-standing 3D film has not been reported so far.

In the rapidly accelerated production of electronic devices and mobile age, necessity of high-energy lithium ion battery with very high specific discharge capacity and prolonged stability is a great requirement to fulfill the demand of the electrochemical energy storage (Yoo et al. 2014). Lithium ion battery, because of flexibility, low cost, light-weight, higher discharge capacity, and longer life span, has been proven the most successful mean than any other comparable battery technologies to fulfill the huge demand of the portable electronic devices and computing technology (Kang and Ceder, 2009). That is why the requirement of Li batteries possessing high charge and discharge rate storage capacities is in great demand in today’s society (Tian et al. 2009). Improvement in lithium ion battery technology is govern by the rapidly invented/tested cathode materials to enhance the discharge capacity and long durability. In this regard, nanomaterials especially nanowires having very high surface area may be proved a better choice. Besides various applications, electrochemical lithium ion storage or as a cathode materials of the Li ion battery, the nanowires can be utilized in a much better way than the bulk materials because of higher energy density and much better cycling lifetime than the bulk materials (Chernova et al. 2009; Goodenough et al. 2007; Armand and Tarascon 2008; Chan et al. 2008; Tarascon and Armand, 2001). Nanomaterials, because of self-aggregation which reduces the effective contact area, have their limitations in many practical applications which can be restored by self-assembly of complex nanostructures into 3D architectures that not only reduce the self-aggregation but maintain the effective area of the active material also (Zhang et al. 2009; Ge et al. 2008; Shi et al. 2007; Mai et al., 2010a, b, 2011a, b).

Our experiments showed that acetonitrile mediated self-assembly of 1D nanowires into 3D spongy-like structures remarkably enhanced the performance of lithium ion batteries. In this study, acetonitrile was used for the first time to assemble 1D β-AgVO3 nanowires into 3D spongy-like hydrogel structures. We found that varying the concentration of acetonitrile from 5 to 20 mL also led to a spongy structure, but with less stable and fragile 3D structure.

Experimental

Synthesis of self-assembled 3D silver vanadate nanostructures

For the synthesis, all necessary chemicals and reagents were bought from Sigma Aldrich and used as received. In a typical experiment, ~ 0.0585 g of ammonium vanadate (NH4VO3) powder was dissolved into 100 mL of distilled water under constant magnetic stirring for 15 min to get a homogeneous 5 mM solution. In another beaker, ~ 0.1699 g of silver nitrate (AgNO3) was dissolved into 95 mL of distilled water and stirred for 15 min to get homogeneous 10 mM solution. Then 5 mL of acetonitrile was added to the AgNO3 solution and stirred for 10 min to get a 100 mL solution. The homogeneous solution of AgNO3 was then mixed suddenly into the NH4VO3 solution, under constant magnetic stirring, while pH and temperature were monitored (by OAKTON pH and temperature meter) to yield a 1:1 volumetric ratio of NH4VO3 to AgNO3. This solution was stirred until the pH was stable (ca. 2 h). Optical images were recorded at different time points (0, 30, 60, 120 min) before putting the solution in the furnace for hydrothermal treatment in order to characterize any change. A yellow-colored precipitate was observed right before putting the mixture in furnace.

Hydrothermal treatment

The obtained solution after 130 min (from previous section) was transferred into a 300-mL stainless steel autoclave and was put in the furnace at 150 °C for 10 h. After the 10 h, the sample was cooled down to room temperature with a cooling rate of 2 °C per minute. A yellow color spongy-like material was obtained at the bottom of the autoclave and transferred easily into a beaker filled with distilled water. Finally, the obtained hydrogel was air-dried to get the film at room temperature.

Structural/microstructural/spectral characterizations

The as-synthesized materials were characterized by X-ray diffractometer (Shimadzu XRD 6000, 40 kV and 30 mA, Cu-Ka radiation) for structural analysis. Spectral analysis such as UV-visible, infrared, Raman, and X-ray photoelectron spectroscopies (XPS) were performed for to characterize the absorption/vibrational modes as well as chemical bonding. UV-visible transitions were recorded using a Shimadzu UV-2450 equipped with an integrating sphere for diffuse reflectance in order to characterize electronic transitions and band gap determination. The surface chemical bonding and surface composition of synthesized materials were characterized by Fourier transform infrared spectroscopy (FTIR) in pressed KBr pellets. The Raman spectra were recorded using Renishaw inVia Raman microscope with 514 nm laser excitation. Thermogravimetric (TGA) analysis was carried out by Q-600 simultaneous TGA/DSC from TA Instruments under Argon atmosphere. The chemical composition was investigated by PHI Quantera XPS, on a PHI-5000C ESCA system with Al Kα X-ray as an excitation source. The shape and morphology of the as-obtained materials were characterized by Zeiss SEM at 30 kV for microstructural characterization, without any metal or carbon coating with the fully dried sample loaded on a copper tape.

Device fabrication for the battery performance

For the lithium ion battery experiments, the device was fabricated in 2032 coin-type cells. The as-synthesized materials was mixed into carbon black (Super-P) and poly(vinyl difluoride) (PVDF) at a weight ratio of 80:10:10 in n-methyl-2-pyrrolidone (NMP) solution to prepare the working electrode. Then the obtained slurry was pasted on an aluminum foil followed by drying under vacuum at 85 °C for 12 h to achieve the cathode. Pure lithium foil bought from Aldrich also served as the counter electrode. The electrolyte was purchased from MTI Corporation, which consists of 1 M LiPF6 in a 1:1:1 mixture of ethylene carbonate (EC)/dimethyl carbonate (DMC)/diethyl carbonate (DEC). Finally, the cells were assembled in glove box in the presence of argon atmosphere with very low level of moisture and oxygen (< 0.1 ppm). The electrochemical performance of the cathode material was tested at various current rates in the voltage range of 1.5–3.5 V.

Results and discussion

Structural/microstructural characterizations

Figure 1 shows the optical photographs of the as-obtained hydrogel just after the hydrothermal treatment. The disc-like yellow color material settled down and was recovered at the bottom of the autoclave. The transparent liquid containing water and by-product were poured out and the material was gently transferred on to a glass substrate for further characterization. Figure 1a (i) and (ii) shows the top and bottom view of the as-obtained 3D spongy-like structure. The diameter of the spongy disc was about 4 cm and the top view was more porous than bottom view. Figure 1a (iii) and (iv) shows the corresponding top and bottom view of the as-obtained 3D structures after dried in air. The film was like a flexible sheet of paper, which can be easily cut into square or rectangular pieces.

a Optical photographs of the as-obtained hydrogel just after the hydrothermal treatment. Images (i) and (ii) show the top and bottom view and (iii) and (iv) show the corresponding top and bottom view after being air-dried. b XRD pattern of the as-prepared yellow color disc-like 3D materials. c FTIR spectra of the material in absorbance mode. d TGA-DTA analysis of the as-synthesized β-AgVO3 nanowires.

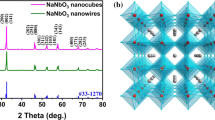

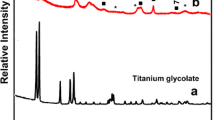

Figure 1b shows the XRD pattern of the as-prepared yellow color disc-like 3D materials. The pattern shows that the 3D product obtained hydrothermally is monoclinic β-AgVO3. All diffraction peaks in the XRD pattern can be well indexed to the monoclinic β-AgVO3 phase (JCPDS card no. 29-1154), with I2/m(12) space group. The (501) diffraction peak is the strongest one, indicating the preferential growth orientation of the β-AgVO3 nanowires. No other peaks except at ~ 38.5° (very low intensity) indicating the formation of silver nanoparticles on the nanowires as reported in some paper (Singh et al. 2010) deduce the pure formation of the product β-AgVO3.

Figure 1c shows the FTIR spectra in absorbance mode. The spectrum shows absorption peaks at 798 and 520 cm−1 that correspond to the symmetric and asymmetric stretching vibration of the V-O bond in the β-AgVO3 structure, respectively. The absorption band at 860 cm−1 can be assigned to the V=O stretching mode. The material does not have any extra peak (due to the residual of the nitrate radicals from the reactants as reported by some authors), which indicates the pure formation of the β-AgVO3 nanowires (Mao et al. 2008). The characteristic absorption peaks of β-AgVO3 are located mainly in the range from 400 to 1000 cm−1, including the stretching vibration mode of the V=O band and symmetric and asymmetric stretching vibration peaks of the V-O band. The peaks at 3448 and 1630 cm−1 (with extremely low intensities) are the stretching and flexural vibrations of the OH in free water, respectively.

The TGA-DTA analysis of the as-synthesized β-AgVO3 nanowires shows that they have good thermal stability under argon atmosphere. Thermogravimetric analysis of as-prepared β-AgVO3 nanowires under argon flow indicates that the material has very less weight loss from room temperature to 900 °C (< 3.5 wt%) as shown in Fig. 1d. The weight loss is much less than ~ 27% weight loss in N2 atmosphere as reported by Mao et al. (2008). The TGA curve of β-AgVO3 nanowires reveals weight loss distribution in two parts due to removal of chemisorbed and physisorbed water. (i) The weight loss of ~ 0.50 wt% can be observed in temperature range 65 to 125 °C which corresponds to the loss of free water. (ii) The weight loss of ~ 2.00 wt% due to the coordinated and physically absorbed water may be observed in the temperature range of 225 to 375 °C as shown by the black line in Fig. 1d. The blue color curve in Fig. 1d represents differential thermal analysis (DTA) of the synthesized β-AgVO3 nanowires which shows mainly one endothermic peak ~ 470 °C, which may correspond to the phase transformation of β-phase into other phase of silver vanadium. This is in consistent to the high temperature XRD graph as reported by D. P. Singh et al. (2010). The temperature range 460–480 °C corresponds to the gradual phase change of β-AgVO3 into Ag and another SVO phase, Ag2V4O11 (having V5+ cation in its structure), which is very stable up to 900 °C. The β-phase of SVO starts to melt at ~ 476 °C (Kittaka et al. 1999, 2002) and completely transforms into V-containing Ag2V4O11 phase at ~ 500 °C which strengthens our as-obtained graphs (Su et al. 2009).

Figure 2 shows the low and high magnification SEM images of the as-synthesized and air-dried, flexible 3D material. Figure 2a shows SEM image of the top view of the ~ 5-mm cut film. Image 2b shows that the film is completely made with superlong nanowires stacked randomly. A large number of homogeneous, flexible, and long nanowires can be seen in Fig. 2c. The higher magnification in Fig. 2d shows that very fine, homogeneous, clean, and variable length/thickness nanowires were self-assembled to form the 3D film-like structure.

Figure 3a shows the SEM image of the bottom side of a piece of the as-obtained 3D film. The bottom side of the film looks more wrinkled in comparison to the top view, probably due to the initial stage of formation (Fig. 3b). These wrinkles are themselves made with very fine nanowires curling in a specific manner. One such kind of wrinkle can be seen in the magnified SEM mage of Fig. 3c. Figure 3d shows that the film and wrinkles both are made with very fine and long nanowires.

The Raman vibrational spectra were recorded for the bonding and the structure determination of as-synthesized material and to distinguish to other phase and molecular structures. Theoretically, the pure β-AgVO3 phase is supposed to show 57 Raman-active modes with 38Ag + 19Bg species and 63 infrared-active modes with 21Au + 42Bu species. The free VO4 3− tetrahedron having Td point-group symmetry can activate four fundamental vibrational modes: ν1 (A1g) symmetric stretching; ν2 (Eg) symmetric deformation; ν3 (F2) asymmetric stretching; ν4 (F2) asymmetric bending (Baran 1997; Benmokhtar et al. 2004). Figure 4a shows the Raman spectra of the as-synthesized β-AgVO3 3D structure. Typical Raman bands around 251, 330, 381, 437, 689, 723, 758, 802, 845, and 881 cm−1 were observed. The number of bands observed here is much less than that predicted, which suggests a great number of band overlapping. In general, V–O bending mode lie in the range 300–400 cm−1; the symmetric and asymmetric stretching modes of bridging V–O–V bonds with intermediate length lie in the ~ 500 and 700 cm−1 regions; and short terminal V=O bonds vibrates with highest frequency and lies in the range higher than 800 cm−1 (Frost et al. 2005; Nordlinder et al. 2003). One of the most intense peaks observed at 881 cm−1 is assigned to the either bridging V-O-Ag or O-V-O vibrations. A weak Raman band observed at 845 cm−1 can be assigned to the stretching vibrations of VO3 groups in the (V2O7)4− ion. The intense band observed at 802 cm−1 corresponds majorly to the symmetric stretching of bridging V–O–V and slightly to the stretching vibration of Ag-O-Ag bonds. The peaks observed at 723 and 758 cm−1 correspond to the asymmetric stretching vibrations of bridging V-O-V bonds (Tian et al. 2005). The symmetric deformation and symmetric bending modes of the VO4 3− tetrahedron can contribute to the Raman bands at 381 and 251 cm−1, respectively (Yu and Kudo 2006; Gotić et al. 2005; Popović et al. 2003). All the Raman peaks are in very good agreement with the peaks reported by Q. Bao et al. (2007a, b). The XPS measurements as shown in Fig. 4b were performed to gather information on the composition and purity of the as-obtained 3D material. In the XPS spectrum, the peak observed at 284.5 eV could be identified to C 1s bond. The peaks corresponding to the elements C, O, Ag, and V only were observed in the spectrum, indicating the pure formation of the product. The high-resolution XPS spectra (Fig. 4c) shows the two peaks located at 529.2 and 536.2 eV corresponding to V2p(3/2) and V2p(1/2), respectively. The other strong peak located at 542.4 eV is attributed to O1s. The two strong peaks at the Ag region of 380.6 and 386.6 eV in Fig. 4d can be assigned to Ag3d(5/2) and Ag3d(3/2). The atomic ratio of the Ag/V/O calculated from the peak area is approximately 1:1:3 which confirms the formation of AgVO3 structure.

a Raman spectrum of the as-synthesized β-AgVO3 3D nanostructure. b Wide-scan XPS spectrum of the as-prepared product. c High-resolution XPS spectrum corresponding to the V2p(3/2), V2p(1/2), and O1s, respectively. d High-resolution XPS spectrum of the silver region showing the Ag3d(5/2) and Ag3d(3/2) peaks

Optical characterizations

In semiconducting material, diffuse reflectance spectra with UV-visible spectrophotometer are a common and standard technique to estimate the band gap energy and the absorption coefficient (López and Gómez 2012; Ebraheem and El-Saied 2013; Karvaly and Hevesi 1971). For the reflectance measurement, powder sample should be too thick to absorb or scatter all the incident light (thickness ~ 1–3). By utilizing the reflectance spectra, the band gap (Eg) can be determined by the Kubelka–Munk (K–M or F(R)) method that offers great advantages. The K–M equation is given by

Where R is the reflectance and F(R) is equivalent to the extinction coefficient (a). This method is applicable to the materials that have high light scattering capacity or the particles absorbed in some matrix. Instead a modified Kubelka–Munk function can also be utilized by multiplying the F(R) function by hν, with a corresponding coefficient (n) associated with various possible electronic transitions given by:

Where h is the Planck’s constant (J.s), and ν is the light frequency (s−1). The band gap of semiconductor particles can be obtained by plotting this function with respect to the energy in electronvolt. Excluding of the factor hν from the equation affects the band gap very slightly. In general for Eg calculation with absorbance spectra, the following equations are used

Where B is the absorption constant, (α) is the extinction coefficient and is proportional to F(R). The values of n are indicated as follows. n = 2 refers indirect allowed transition (graph between α(hν)1/2 versus E); n = 3 refers an indirect forbidden transition (graph between α(hν)1/3 versus E); n = 1/2 refers a direct allowed transition (graph between α(hν)2 versus E); n = 3/2 refers a direct forbidden transition (graph between α(hν)2/3 versus E). For the band gap calculation, first the recorded reflectance spectrum is transformed to an F(R) magnitude and plotted versus hν and then Eg value is obtained by extrapolating the slope to α = 0.

Various authors have utilized different ways for the graphical representation and band gap calculations for example, Khan et al. (2002) calculated the band gap of TiO2 material by directly plotting the graph between absorbance and k and Graf et al. (2007) estimated the Eg by plotting %R versus k. In contrast, various authors utilized the K–M function F(R) versus hν for the calculation of band gap (Yang et al. 2014; Kubelka, 1948). Various other authors utilized the modified K–M function and calculated the band gap by plotting the (F(R) hν)1/2 versus hν or (F(R) hν)2 versus hν depending on the corresponding coefficients of transitions (Lin et al. 2006; Yeredla and Xu 2008; Aguado et al. 2006). Based on the discussion above, Fig. 5 shows the UV-visible reflectance spectrum, band gap calculation, and photoresponse of the 3D film. Figure 5a shows the as-obtained reflectance spectra recorded between 250 and 700 nm. Figure 5b represents the band gap calculation by plotting the (%R) versus hν and extrapolating the slope to α = 0 as calculated by Graf et al. (2007). Figure 5c shows the band gap calculation by the modified K–M function as described in Eq. 2 for the direct allowed transition. Since β-AgVO3 is a direct transition semiconductor, Eg will be given by the curve (F(R) hν)1/2 versus hν and extrapolating it to the α = 0 (Aguado et al. 2006). The band gap calculated by this comes out to be 2.8 eV, which is same as the band gap calculated by simply (%R) versus hν as shown in Fig. 5b.

In order to study the current through the 3D β-AgVO3 film, the film was analyzed in a four-probe arrangement. Figure 5d shows the typical current versus voltage curves measured in dark and under illumination. The both curves show good linear behavior, which proves a satisfactory ohmic contact between the film and electrodes. In the graph, an increment in the conductivity of the film can be observed under illumination. In these cases, the photons having the energy greater than band gap excite the electrons in the β-AgVO3 film from the valence band into the conduction band, creating an electron hole pair which not only increases the charge carrier concentration but enhances the conductivity also.

Lithium ion battery performance

The as-obtained flexible 3D film of silver vanadate nanowires was further tested for the electrochemical charge/discharge performance and stability with the testing potential range of 1.5–3.5 V (vs. Li/Li+). Figure 6a summarizes the discharge/charge profiles of 3D silver vanadate electrode at constant current density of 50 mA g−1 for the 1st, 2nd, 5th, 50th cycle. The charge/discharge characteristics were performed at low current density (e.g., 50 mA g−1), which can be explained from the equation of the lithium ion diffusion at the electrode material and is given by τ = L 2/2D, where τ is diffusion time, L is diffusion distance, and D is lithium ion diffusion coefficient (Levi et al. 1999). The τ is longer and discharge capacity is higher when the electrode material is discharged at low current density, in comparison to high current density. It is important to mention that discharging of cathode materials at low current density causes various drawbacks also for example structural degradation of the material, volume expansion, and a rapid capacity decay also at subsequent cycles. Instead of low current density, discharging at high current density leads to the intercalation/deintercalation of Li+ near the surface of the electrode material, which shorter the Li+ diffusion distance and keeps the structure of the material stable except the low capacity at initial several cycles. But as far as the cycling stability of electrode material is concerned, it is much better than at low current density. This is in good agreement with the report Fang et al. (2015) where specific discharge capacities were recorded for potassium vanadate K0.25V2O5 materials at various current densities of 50, 100, 200, 500, and 1000 mA g−1 but highest specific discharge capacities of 256 mAh g−1 was achieved at 50 mA g−1.

Figure 6b shows the high capacity and excellent cycling stability of 3D silver vanadate nanostructure. The battery was cycled between 1.5 and 3.5 V at a charge/discharge current density of 50 mA g−1. The 3D nanowire cathode initial and 70th discharge capacities are 162 and 86 mAh g−1 (with 50th cycle capacity retention of 53%). The 3D structure possesses 83% cyclic capacity retention after 20th cycle, which is much higher than the 62% capacity retention after 20th cycle as reported by Mai et al. (2011a, b) in the silver vanadium oxides/polyaniline triaxial nanowires. The capacity retention after 50th cycle 61% is much higher than that reported by Han et al. (2012) where he utilized the substrate-assisted self-organized radial β-AgVO3 nanowire clusters (41%) as a cathode material. This better performance in comparison to other researchers is due to the self-assembled structure of the silver vanadate nanowires.

In Fig. 6a, the specific capacities at 1st, 2nd, 5th, and 50th are 165, 140, 120, and 100 mAh g−1 are presented, which indicate that the material has still very good capacity even after 50th cycle and interestingly more clear plateau of discharge. This figure also shows good lithium ion intercalation/deintercalation plateaus at higher cycle as shown in green color at 50th cycle. The curves exhibit two distinct plateaus at about 3.2 and 2.3 V for the discharge curve and one clear plateau around 2.85 V for charge curve that are in agreement with the two strong cathodic peaks located at 2.64 and 2.15 V, and two anodic peaks seen at 2.89 and 3.55 V as reported in the CV curve by Zhang et al. (2006).

On the basis of above results and discussion, the lithium ions intercalation into β-AgVO3 nanowires can be understood via two steps as clearly observed by discharge plateau curve in Fig. 6a. The first stage involves the reduction of Ag+ in to Ag0 between the vanadium oxide octahedrons layers and deposition as metallic silver. At the same time, the lithium ions inserted, occupy the corresponding available sites between the layers. Furthermore in the second stage of the discharge process, the reduction of vanadium takes place instead of silver.

In this stage, during the second range of discharge curve, the V5+ reduces to V4+, and there is also a partial reduction from V4+ to V3+. These results and explanation are in agreement with the in situ Raman measurements followed by a proposed computer simulated model for the lithium insertion in the channel-structured of β-AgVO3 by Bao et al. (2007a, b).

Growth mechanism

Acetonitrile is a highly polar liquid (μ = 3.9 D) and because of its physical behavior, as well as its importance as a widely used solvent, considerable interests have been shown in studies related to its structure in liquid solutions (Yarwood 1979). Acetonitrile contains molecules with antiparallel molecular orientation and because of such alignment it is deduced that the charges of the dipoles are located at the ends of the molecules and not on the nitrile group. The center of the dipole and the center of the molecule are therefore similarly placed.

The silver ion interaction with acetonitrile in aqueous and non-aqueous media is one of the most interesting classical problem of ion + solvent interactions. From the independent thermodynamic measurements and NMR studies, Fromon et al. (1982) deduced the formation at least two complexes of silver and acetonitrile ions. He deduced on the basis of the values of the corresponding formation constants that in water, there is possibility of formation of both (AgACN)+ and [Ag(ACN)2 +(ACN = acetonitrile)]. The formation of both complexes and equilibrium can be given as follows:

Since the [Ag(CH3CN)2]+ phase with acetonitrile is very less stable, there is more chance of the formation of (Ag CH3CN)+. In another study based on Raman and infrared studies, Chang and Irish (1974) deduced that in this system Ag+ ion is solvated by four molecules -of CH3CN; nitrate ion replaces three of these when bound to Ag+. By applying a different approach, Oliver and Janz (1970) also reported a value of 4 in the AgNO3-CH3CN. Therefore, the equilibrium in the system may be given as

The above equation specifies that one NO3 − displaces three CH3CN molecules. The reaction between the ammonium metavanadate and silver nitrate complex can be given as:

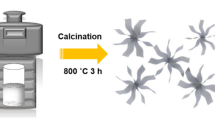

Figure 7a is a framework and 3D representation for the formation of silver vanadate structure as discussed above. Figure 7b represents the growth of 3D AgVO3 structures as fine long AgVO3 nanowires. The figure depicts that the first nucleation and formation of AgVO3 nanowires starts just after mixing the solution, which was also confirmed by the yellow color precipitate of the solution. Hydrothermal treatment gradually increased the length of the nanowires and assembled them into a 3D porous spongy-like structure, which settles down at the bottom of the autoclave after the reaction is completed. A step-by-step formation of nanowires and self-assembly into 3D structure can be seen in Fig. 7b.

Figure 8a shows the pH and temperature variation curve during the mixing of the solution of AgNO3, ACN solution with ammonium vanadate solution. An initial orange color, which turned yellow after 130 min, was observed as shown in Fig. 8b. The pH curve is quite similar to the pH curve we reported previously (Singh et al. 2010) for the room temperature synthesis of silver vanadate nanowires. The only difference is that for our previous work the pH saturated after 40 min whereas it took 1 h and 20 min to saturate in the presence of acetonitrile. Besides a broad deep valley in the curve from 20 to 80 min can be seen, which is different from our earlier report in the absence of acetonitrile. Probably the presence of acetonitrile changed the reaction kinetics as shown by above Eqs. (6) and (7). There is always a gradual and almost linear increase in temperature during reaction, which shows the exothermic nature of the reaction. The similar color of the precipitate to the one in the absence of ACN suggests the formation of α-AgVO3 nanowires (Supplementary informations). Acetonitrile medium and the hydrothermal treatment transformed the nanowires into the β-AgVO3 phase. Thus acetonitrile played a major role for the growth of ultralong nanowires and self-assemble into 3D spongy-like structures.

Conclusions

In summary, β-AgVO3 nanowires have been synthesized and assembled into 3D porous spongy-like structures in the presence of highly polar liquid acetonitrile. As suggested by the formation and growth mechanism, acetonitrile played an important role to grow long nanowires and assemble them into 3D structures. This 3D structure exhibited very high specific discharge capacities of 165 mAh g−1 in the first cycle and 100 mAh g−1 till 50th cycle with a cyclic capacity retention of 53% at a current density of 50 mA g−1. The presented photoresponse of this material suggests that this material can also be used as photo-switches.

References

Aguado J, Vangrieken R, Lopez-Muñoz MJ, Marugan J (2006) A comprehensive study of the synthesis, characterization and activity of TiO2 and mixed TiO2/SiO2 photocatalysts. Appl Catal A Gen 312:202–212. doi:10.1016/j.apcata.2006.07.003

Armand M, Tarascon JM (2008) Building better batteries. Nature 451:652–657. doi:10.1038/451652a

Bao Q, Bao S, Li CM, Qi X, Pan C, Zang J, Wang W, Tang DY (2007a) Lithium insertion in channel-structured β-AgVO3: in situ Raman study and computer simulation. Chem Mater 19:5965–5972. doi:10.1021/cm071728i

Bao SJ, Bao QL, Li CM, Chen TP, Sun CQ, Dong ZL, Gan Y, Zhang J (2007b) Synthesis and electrical transport of novel channel-structured β-AgVO3. Small 3:1174–1177. doi:10.1002/smll.200700032

Baran EJ (1997) Vibrational spectra of Ba2(VO)V2O8. J Raman Spectrosc 28:289–291. doi:10.1002/(SICI)1097-4555(199607)27:73.3.CO;2-Q

Benmokhtar S, El Jazouli A, Chaminade JP, Gravereau P, Guillen F, de Waal D (2004) Synthesis, crystal structure and optical properties of BiMgVO5. J Solid State Chem 177:4175–4182. doi:10.1016/j.jssc.2004.06.030

Cao AM, Hu JS, Liang HP, Wan LJ (2005) Self-assembled vanadium pentoxide (V2O5) hollow microspheres from nanorods and their application in lithium-ion batteries. Angew Chemie Int Ed 44:4391–4395. doi:10.1002/anie.200500946

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35. doi:10.1038/nnano.2007.411

Chang TG, Irish DE (1974) Solvation and ion association in the system AgNO3-CH3CN: a Raman and infrared spectral study. J Solut Chem 3:161–174. doi:10.1007/BF00645631

Chernova NA, Roppolo M, Dillon AC, Whittingham MS (2009) Layered vanadium and molybdenum oxides: batteries and electrochromics. J Mater Chem 19:2526–2552. doi:10.1039/b819629j

Das DP, Barik RK, Das J, Mohapatra P, Parida KM (2012) Visible light induced photo-hydroxylation of phenol to catechol over RGO–Ag3VO4 nanocomposites without the use of H2O2. RSC Adv 2:7377–7379. doi:10.1039/c2ra20703f

Ebraheem S, El-Saied A (2013) Band gap determination from diffuse reflectance measurements of irradiated lead borate glass system doped with TiO2 by using diffuse reflectance technique. Mater Sci Appl 04:324–329. doi:10.4236/msa.2013.45042

Fang G, Zhou J, Hu Y, Cao X, Tang Y, Liang S (2015) Facile synthesis of potassium vanadate cathode material with superior cycling stability for lithium ion batteries. J Power Sources 275:694–701. doi:10.1016/j.jpowsour.2014.11.052

Feng M, Luo LB, Nie B, Yu SH (2013) P-type beta-silver vanadate nanoribbons for nanoelectronic devices with tunable electrical properties. Adv Funct Mater 23:5116–5122. doi:10.1002/adfm.201300413

Fromon M, Treiner C, Convert O, Sundheim BC (1982) NMR study of dilute ternary solutions: acetonitrile, silver nitrate and other electrolytes in water at 25°C. Polyhedron 1:145–148. doi:10.1016/S0277-5387(00)80975-4

Frost RL, Erickson KL, Weier ML, Carmody O (2005) Raman and infrared spectroscopy of selected vanadates. Spectrochim Acta A Mol Biomol Spectrosc 61:829–834. doi:10.1016/j.saa.2004.06.006

Ge J, Zhang Q, Zhang T, Yin Y (2008) Core-satellite nanocomposite catalysts protected by a porous silica shell: controllable reactivity, high stability, and magnetic recyclability. Angew Chemie Int Ed 47:8924–8928. doi:10.1002/anie.200803968

Goodenough JB (2007) Cathode materials: a personal perspective. J Power Sources 174:996–1000. doi:10.1016/j.jpowsour.2007.06.217

Gotić M, Musić S, Ivanda M, Šoufek M, Popović S (2005) Synthesis and characterization of bismuth(III) vanadate. J Mol Struct 744:535–540. doi:10.1016/j.molstruc.2004.10.075

Graf C, Ohser-Wiedemann R, Kreisel G (2007) Preparation and characterization of doped metal-supported TiO2-layers. J Photochem Photobiol A Chem 188:226–234. doi:10.1016/j.jphotochem.2006.12.019

Han C, Pi Y, An Q, Mai L, Xie J, Xu X, Xu L, Zhao Y, Niu C, Khan AM, He X (2012) Substrate-assisted self-organization of radial β-AgVO3 nanowire clusters for high rate rechargeable lithium batteries. Nano Lett 12:4668–4673. doi:10.1021/nl301993v

Holtz RD, Souza FAG, Brocchi M, Martins D, Durán N, Alves OL (2010) Development of nanostructured silver vanadates decorated with silver nanoparticles as a novel antibacterial agent. Nanotechnology 21:185102–185110. doi:10.1088/0957-4484/21/18/185102

Jang SH, Yoon JH, Huh YD, Yoon S (2014) Creating SERS hot spots on ultralong single-crystal β-AgVO3 microribbons. J Mater Chem C 2:4051–4056. doi:10.1039/C4TC00078A

Kang B, Ceder G (2009) Battery materials for ultrafast charging and discharging. Nature 458:790–793. doi:10.1038/nature07853

Karvaly B, Hevesi I (1971) Investigations on diffuse reflectance spectra of V2O5 powder Zeitschrift fur Naturforsch. Sect A J Phys Sci 26:245–249. doi:10.1515/zna-1971-0211

Khan SUM, Al-Shahry M, Ingler WB (2002) Efficient photochemical water splitting by a chemically modified n-TiO2. Science 297:2243–2245. doi:10.1126/science.1075035

Kittaka S, Matsuno K, Akashi H (1999) Crystal structure of α-AgVO3and phase relation of AgVO3. J Solid State Chem 142:360–367. doi:10.1006/jssc.1998.8044

Kittaka S, Nishida S, Iwashita T, Ohtani T (2002) Reactivity and structural properties of a mechanocehmically treated Ag2O-V2O5 system in relation to AgVO3 polymorphs. J Solid State Chem 164:144–149. doi:10.1006/jssc.2001.9461

Kittaka S, Yata Y, Matsuno K, Nishido H (2000) Interaction of Ag ions with a vanadium pentoxide hydrate—formation of silver vanadate at low temperature. J Mater Sci 35:2185–2192. doi:10.1023/A:1004762506710

Kubelka P (1948) New contributions to the optics of intensely light-scattering materials. Part I J Opt Soc Am 38:448–457. doi:10.1364/JOSA.38.000448

Levi MD, Gamolsky K, Aurbach D, Heider U, Oesten R (1999) Determination of the Li ion chemical diffusion coefficient for the topotactic solid-state reactions occurring via a two-phase or single-phase solid solution pathway. J Electroanal Chem 477:32–40. doi:10.1016/S0022-0728(99)00386-1

Liang L, Xu Y, Lei Y, Liu H (2014) 1-Dimensional AgVO3 nanowires hybrid with 2-dimensional graphene nanosheets to create 3-dimensional composite aerogels and their improved electrochemical properties. Nano 6:3536–3539. doi:10.1039/c3nr06899d

Lin H, Huang CP, Li W, Ni C, Shah SI, Tseng YH (2006) Size dependency of nanocrystalline TiO2 on its optical property and photocatalytic reactivity exemplified by 2-chlorophenol. Appl Catal B Environ 68:1–11. doi:10.1016/j.apcatb.2006.07.018

Liu H, Tian Y, Amal R, Wang D (2016) An integrated nanocarbon–cellulose membrane for solid-state supercapacitors. Sci Bull 61:368–377. doi:10.1007/s11434-016-1019-9

Liu J, Wang X, Peng Q, Li Y (2005) Vanadium pentoxide nanobelts: highly selective and stable ethanol sensor materials. Adv Mater 17:764–767. doi:10.1002/adma.200400993

Liu S, Wang W, Zhou L, Zhang L (2006) Silver vanadium oxides nanobelts and their chemical reduction to silver nanobelts. J Cryst Growth 293:404–408. doi:10.1016/j.jcrysgro.2006.05.045

López R, Gómez R (2012) Band-gap energy estimation from diffuse reflectance measurements on sol-gel and commercial TiO2: a comparative study. J Sol-Gel Sci Technol 61:1–7. doi:10.1007/s10971-011-2582-9

Lu H, Deng K, Yan N, MaY GB, Wang Y, Li L (2016) Efficient perovskite solar cells based on novel three-dimensional TiO2 network architectures. Sci Bull 61:778–786. doi:10.1007/s11434-016-1050-x

Mai L, Xu L, Gao Q, Han C, Hu B, Pi Y (2010a) Single β-AgVO3 nanowire H2S sensor. Nano Lett 10:2604–2608. doi:10.1021/nl1013184

Mai L, Xu L, Han C, Xu X, Luo Y, Zhao S, Zhao Y (2010b) Electrospun ultralong hierarchical vanadium oxide nanowires with high performance for lithium ion batteries. Nano Lett 10:4750–4755. doi:10.1021/nl103343w

Mai L, Xu X, Han C, Luo Y, Xu L, Wu YA, Zhao Y (2011a) Rational synthesis of silver vanadium oxides/polyaniline triaxial nanowires with enhanced electrochemical property. Nano Lett 11:4992–4996. doi:10.1021/nl202943b

Mai LQ, Yang F, Zhao YL, Xu X, Xu L, Luo YZ (2011b) Hierarchical MnMoO4/CoMoO4 heterostructured nanowires with enhanced supercapacitor performance. Nat Commun 2:381–385. doi:10.1038/ncomms1387

Mao C, Wu X, Zhu JJ (2008) Large scale preparation of β-AgVO3 nanowires using a novel sonochemical route. J Nanosci Nanotechnol 8:3203–3207. doi:10.1166/jnn.2008.102

Nordlinder S, Lindgren J, Gustafsson T, Edström K (2003) The structure and electrochemical performance of Na+, K+, and Ca2+- vanadium oxide nanotubes. J Electrochem Soc 150:E280–E284. doi:10.1149/1.1566414

Oliver BG, Janz GJ (1970) Raman spectra of silver nitrate in water-acetonitrile mixtures. J Phys Chem 7:3819–3822. doi:10.1021/j100715a017

Popovi ZV, Konstantinovi MJ, Moshchalkov VV, Isobe M, Ueda Y (2003) Raman scattering study of charge ordering in β-Ca0.33V2O5. J Phys Condens Matter 15:L139–L145

Shao MW, Lu L, Wang H, Wang S, Zhang ML, Ma DDD, Lee ST (2008) An ultrasensitive method: surface-enhanced Raman scattering of Ag nanoparticles from β-silver vanadate and copper. Chem Commun 7345:2310–2312. doi:10.1039/b802405g

Sharma S, Panthöfer M, Jansen M, Ramanan A (2005) Ion exchange synthesis of silver vanadates from organically templated layered vanadates. Mater Chem Phys 91:257–260. doi:10.1016/j.matchemphys.2004.08.024

Shi S, Cao M, He X, Xie H (2007) Surfactant-assisted hydrothermal growth of single-crystalline ultrahigh-aspect-ratio vanadium oxide nanobelts. Cryst Growth Des 7:1893–1897. doi:10.1021/cg060847s

Singh DP, Polychronopoulou K, Rebholz C, Aouadi SM (2010) Room temperature synthesis and high temperature frictional study of silver vanadate nanorods. Nanotechnology 21:325601–325608. doi:10.1088/0957-4484/21/32/325601

Song JM, Lin YZ, Yao HB, Fan FJ, Li XG, Yu SH (2009) Superlong beta-AgVO3 nanoribbons: high-yield synthesis by a pyridine-assisted solution approach, their stability, electrical and electrochemical properties. ACS Nano 3:653–360. doi:10.1021/nn800813s

Su Q, Huang CK, Wang Y, Fan YC, Lu BA, Lan W, Wang YY, Liu XQ (2009) Formation of vanadium oxides with various morphologies by chemical vapor deposition. J Alloys Compd 475:518–523. doi:10.1016/j.jallcom.2008.07.078

Takeuchi ES, Piliero P (1987) Lithium/silver vanadium oxide batteries with various silver to vanadium ratios. J Power Sources 21:133–141. doi:10.1016/0378-7753(87)80044-7

Takeuchi KJ, Marschilok AC, Davis SM, Leising RA, Takeuchi ES (2001) Silver vanadium oxides and related battery applications. Coord Chem Rev 219-221:283–310. doi:10.1016/S0010-8545(01)00340-X

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414:359–367. doi:10.1038/35104644

Tian B, Xie P, Kempa TJ, Bell DC, Lieber CM (2009) Single-crystalline kinked semiconductor nanowire superstructures. Nat Nanotechnol 4:824–829. doi:10.1038/nnano.2009.304

Tian H, Wachs IE, Briand LE (2005) Comparison of UV and visible Raman spectroscopy of bulk metal molybdate and metal vanadate catalysts. J Phys Chem B 109:23491–23499. doi:10.1021/jp053879j

Whittingham MS (2004) Lithium batteries and cathode materials. Chem Rev 104:4271–4301. doi:10.1021/cr020731c

Xie J, Cao X, Li J, Zhan H, Xia Y, Zhou Y (2005) Application of ultrasonic irradiation to the sol-gel synthesis of silver vanadium oxides. Ultrason Sonochem 12:289–293. doi:10.1016/j.ultsonch.2004.01.041

Xiong J, Han C, Li Z, Dou S (2015) Effects of nanostructure on clean energy: big solutions gained from small features. Sci Bull 60:2083–2090. doi:10.1007/s11434-015-0972-z

Yang YM, Liu YY, Huang BB, Zhang R, Dai Y, Qin XY, Zhang XY (2014) Enhanced visible photocatalytic activity of a BiVO4@beta-AgVO3 composite synthesized by an in situ growth method. RSC Adv 4:20058–20061. doi:10.1039/c4ra02110j

Yarwood J (1979) Spectroscopic studies of intermolecular forces in dense phases. Annu Rep Prog Chem 79:99–130. doi:10.1039/PC9797600099

Yeredla RR, Xu H (2008) An investigation of nanostructured rutile and anatase plates for improving the photosplitting of water. Nanotechnology 19:055706. doi:10.1088/0957-4484/19/05/055706

Yoo HD, Markevich E, Salitra G, Sharon D, Aurbach D (2014) On the challenge of developing advanced technologies for electrochemical energy storage and conversion. Mater Today 17:110–121. doi:10.1016/j.mattod.2014.02.014

Yu J, Kudo A (2006) Effects of structural variation on the photocatalytic performance of hydrothermally synthesized BiVO4. Adv Funct Mater 16:2163–2169. doi:10.1002/adfm.200500799

Zhang Q, Wang W, Goebl J, Yin Y (2009) Self-templated synthesis of hollow nanostructures. Nano Today 4:494–507. doi:10.1016/j.nantod.2009.10.008

Zhang S, Li W, Li C, Chen J (2006) Synthesis, characterization, and electrochemical properties of Ag2V4O11 and AgVO3 1-D nano/microstructures. J Phys Chem B 110:24855–24863. doi:10.1021/jp065478p

Zhou Q, Shao M, Que R, Cheng L, Zhuo S, Tong Y, Lee ST (2011) Silver vanadate nanoribbons: a label-free bioindicator in the conversion between human serum transferrin and apotransferrin via surface-enhanced Raman scattering. Appl Phys Lett 98:193110–193112. doi:10.1063/1.3590712

Acknowledgements

Authors D. P. Singh and J. C. Denardin acknowledge with gratitude the financial supports from CONICYT Fondeyt Regular 1151527 and CONICYT BASAL CEDENNA FB0807, Chile respectively. R. M. Yadav acknowledges the financial support from UGC India for Raman Fellowship. A. A. Marti acknowledges the Welch Foundation (grant C-1743) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by CONICYT Chile (Fondeyt Regular 1151527), UGC India for (Raman Fellowship), and Welch Foundation (grant C-1743) USA.

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

Supporting data available for XRD, SEM images and description of the as synthesized materials before putting in thefurnace (DOCX 1.10 mb)

Rights and permissions

About this article

Cite this article

Klockner, W., Yadav, R.M., Yao, J. et al. Acetonitrile mediated facile synthesis and self-assembly of silver vanadate nanowires into 3D spongy-like structure as a cathode material for lithium ion battery. J Nanopart Res 19, 288 (2017). https://doi.org/10.1007/s11051-017-3983-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-017-3983-7