Abstract

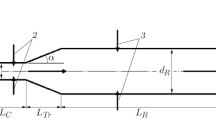

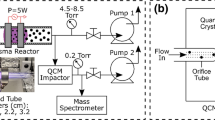

The influence of the time-temperature history on the characteristics of nanoparticles such as size, degree of agglomeration, or crystallinity is investigated for chemical vapor synthesis (CVS). A simple reaction-coagulation-sintering model is used to describe the CVS process, and the results of the model are compared to experimental data. Nanocrystalline titania is used as model material. Titania nanoparticles are generated from titanium-tetraisopropoxide (TTIP) in a hot-wall reactor. Pure anatase particles and mixtures of anatase, rutile (up to 11 vol.%), and brookite (up to 29 vol.%) with primary particle sizes from 1.7 nm to 10.5 nm and agglomerate particle sizes from 24.3 nm to 55.6 nm are formed depending on the particle time-temperature history. An inductively heated furnace with variable inductor geometry is used as a novel system to control the time-temperature profile in the reactor externally covering a large wall temperature range from 873 K to 2023 K. An appropriate choice of inductor geometry, i.e. time-temperature profile, can significantly reduce the degree of agglomeration. Other particle characteristics such as crystallinity are also substantially influenced by the time-temperature profile.

Similar content being viewed by others

References

Ali M, Friedenberger N, Spasova M, Winterer M (2009) A novel approach for chemical vapor synthesis of ZnO nanocrystals: optimization of yield, crystallinity. Chem Vap Depos 15:192–198. doi:10.1002/cvde.200806722

Bai J, Zhou B (2014) Titanium dioxide nanomaterials for sensor applications. Chem Rev 114:10131–10176. doi:10.1021/cr400625j

Buesser B, Pratsinis SE (2012) Design of nanomaterial synthesis by aerosol processes. Annu Rev Chem Biomol Eng 3:103–127. doi:10.1146/annurev-chembioeng-062011-080930

Chen X, Mao SS (2007) Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem Rev 107:2891–2959. doi:10.1021/cr0500535

Chiang Y-M, Birnie D, Kingery WD (1997) Physical ceramics: principles for ceramic science and engineering. Wiley, New York, p 187

Djenadic R, Chowdhury SR, Spasova M, Gondorf A, Akyildiz E, Winterer M (2007) Influence of the time-temperature-profile on powder characteristics of nanocrystalline anatase (TiO2) produced by chemical vapor synthesis. MRS Proc 1056:1056–HH08–07. doi: 10.1557/PROC-1056-HH08–07

Djenadic R, Winterer M (2012) Chemical vapor synthesis of nanocrystalline oxides. In: Lorke A, Winterer M, Schmechel R, Schulz C (eds) Nanoparticles from the gasphase. Springer, Berlin Heidelberg, p 49

Eggersdorfer ML, Kadau D, Herrmann HJ, Pratsinis SE (2012) Aggregate morphology evolution by sintering: number and diameter of primary particles. J Aerosol Sci 46:7–19. doi:10.1016/j.jaerosci.2011.11.005

Eggersdorfer ML, Pratsinis SE (2014) Agglomerates and aggregates of nanoparticles made in the gas phase. Adv Powder Technol 25:71–90. doi:10.1016/j.apt.2013.10.010

Flagan RC, Lunden MM (1995) Particle structure control in nanoparticle synthesis from the vapor phase. Mater Sci Eng A 204:113–124. doi:10.1016/0921-5093(95)09947-6

Friedlander SK (2000) Smoke, dust, and haze: fundamentals of aerosol dynamics, 2nd edn. Oxford University Press, Oxford, p 346

Goudeli E, Eggersdorfer ML, Pratsinis SE (2015) Coagulation–agglomeration of fractal-like particles: structure and self-preserving size distribution. Langmuir 31:1320–1327. doi:10.1021/la504296z

Guo Q, Zhou C, Ma Z, Ren Z, Fan H, Yang X (2016) Elementary photocatalytic chemistry on TiO2 surfaces. Chem Soc Rev 45:3701–3730. doi:10.1039/c5cs00448a

Grass RN, Tsantilis S, Pratsinis SE (2006) Design of high-temperature, gas-phase synthesis of hard or soft TiO2 agglomerates. AICHE J 52:1318–1325. doi:10.1002/aic.10739

Hao X, Zhao H, Xu Z, Zheng C (2013) Population balance-Monte Carlo simulation for gas-to-particle synthesis of nanoparticles. Aerosol Sci Technol 47:1125–1133. doi:10.1080/02786826.2013.823642

Hinds WC (2001) Physical and chemical changes in the particulate phase. In: Baron PA, Willeke K (eds) Aerosol measurement. Wiley, New York, p 98

Hoefler HJ, Averback RS (1992) Sinter-forging of nanocrystalline TiO2, MRS Symp. Proc 286:9–14

Howard CJ, Sabine TM, Dickson F (1991) Structural and thermal parameters for rutile and anatase. Acta Crystallogr Sect B Struct Sci 47:462–468. doi:10.1107/S010876819100335X

Kammler HK, Mädler L, Pratsinis SE (2001) Flame synthesis of nanoparticles. Chem Eng Technol 24:583–596. doi:10.1002/1521-4125(200106)24:6<583::AID-CEAT583>3.0.CO;2-H

Klein S, Winterer M, Hahn H (1998) Reduced-pressure chemical vapor synthesis of nanocrystalline silicon carbide powders. Chem Vap Depos 4:143–149

Knieke C, Sommer M, Peukert W (2009) Identifying the apparent and true grinding limit. Powder Technol 195:25–30. doi:10.1016/j.powtec.2009.05.007

Kruis FE, Kusters K a, Pratsinis SE, Scarlett B (1993) A simple model for the evolution of the characteristics of aggregate particles undergoing coagulation and sintering. Aerosol Sci Technol 19:514–526. doi:10.1080/02786829308959656

Lee Penn R, Banfield JF (1998) Oriented attachment and growth, twinning, polytypism, and formation of metastable phases: insights from nanocrystalline TiO2. Am Mineral 83:1077–1082

Liao SC, Mayo WE, Pae KD (1997) Theory of high pressure/low temperature sintering of bulk nanocrystalline TiO2. Acta Mater 45:4027–4040. doi:10.1016/S1359-6454(97)00087-6

Lowell S, Shields JE, Thomas MA, Thommes M (2004) Characterization of porous solids and powders: surface area, pore size and density. Springer Netherlands, Dordrecht, p 18

Lutterotti L, Scardi P (1990) Simultaneous structure and size-strain refinement by the Rietveld method. J Appl Crystallogr 23:246–252. doi:10.1107/S0021889890002382

Meagher E, Lager G (1979) Polyhedral thermal expansion in the TiO2 polymorphs: refinement of the crystal structures of rutile and brookite at high temperature. Can Mineral 17:77–85

Mulvaney, P (1998), Chaper 12: zeta potential and colloid reaction kinetics. In Fendler, JH (ed.), Nanoparticles and nanostructured films, Wiley-VCH, Weinheim, p 300

Nakaso K, Okuyama K, Shimada M, Pratsinis SE (2003) Effect of reaction temperature on CVD-made TiO2 primary particle diameter. Chem Eng Sci 58:3327–3335. doi:10.1016/S0009-2509(03)00213-6

Notthoff C, Schilling C, Winterer M (2012) Gas temperature measurements inside a hot wall chemical vapor synthesis reactor. Rev Sci Instr 83:114904 . doi:10.1063/1.4766956 6pp

Park HK, Park KY (2015) Control of particle morphology and size in vapor-phase synthesis of titania, silica and alumina nanoparticles. KONA Powd Part J 32:85–101. doi:10.14356/kona.2015018

Pfanzelt M, Kubiak P, Fleischhammer M, Wohlfahrt-Mehrens M (2011) TiO2 rutile - an alternative anode material for safe lithium-ion batteries. J Power Sources 196:6815–6821. doi:10.1016/j.jpowsour.2010.09.109

Pratsinis SE (1988) Simultaneous nucleation, condensation, and coagulation in aerosol reactors. J Colloid Interface Sci 124:416–427. doi:10.1016/0021-9797(88)90180-4

Raj CC, Prasanth R (2016) A critical review of recent developments in nanomaterials for photoelectrodes in dye sensitized solar cells. J Power Sources 317:120–132. doi:10.1016/j.jpowsour.2016.03.016

Schilling C, Winterer M (2014) Preserving particle characteristics at increasing production rate of ZnO nanoparticles by chemical vapor synthesis. Chem Vap Depos 20:138–145. doi:10.1002/cvde.201307094

Swihart MT (2003) Vapor-phase synthesis of nanoparticles. Curr Opin Colloid Interface Sci 8:127–133. doi:10.1016/S1359-0294(03)00007-4

Syvitski JPM (1991) Principles, methods and application of particle size analysis. Cambridge University Press, Cambridge, p 334

Tsantilis S, Kammler HK, Pratsinis SE (2002) Population balance modeling of flame synthesis of titania nanoparticles. Chem Eng Sci 57:2139–2156. doi:10.1016/S0009-2509(02)00107-0

Tsantilis S, Pratsinis SE (2004) Soft- and hard-agglommerate aerosols made at high temperatures. Langmuir 20:5933–5939

Winterer M (2002) Nanocrystalline ceramics—synthesis and structure. Springer, Berlin, p 65

Zhang H, Banfield JF (1998) Thermodynamic analysis of phase stability of nanocrystalline titania. J Mater Chem 8:2073–2076. doi:10.1039/a802619j

Zhang J, Li M, Feng Z et al (2006) UV Raman spectroscopic study on TiO2. I. Phase transformation at the surface and in the bulk. J Phys Chem B 110:927–935. doi:10.1021/jp0552473

Acknowledgements

This work was granted by the German Research Foundation (DFG) through the Collaborative Research Center SFB 445. We would like to thank Dr. Marina Spasova (Experimental Physics Department University Duisburg-Essen, Germany) and Dr. Ralf Theissmann (Institute for Nanostructures and Technology, University Duisburg-Essen, Germany) for the TEM imaging.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Djenadic, R., Winterer, M. Control of nanoparticle agglomeration through variation of the time-temperature profile in chemical vapor synthesis. J Nanopart Res 19, 28 (2017). https://doi.org/10.1007/s11051-016-3714-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-016-3714-5