Abstract

Aggregation-free spherical lanthanum-doped bismuth titanate (Bi3.25La0.75Ti3O12, BLT) gel particles with an average size of about 150 nm were successfully obtained from an inverse miniemulsion sol–gel process, with Span-80 acting as surfactant, n-butanol as co-surfactant, cyclohexane as continuous phase, and submicro-droplets of aqueous solution containing Bi3+, La3+ and Ti4+ ions as dispersed phase, and then topotactically transformed into highly dispersed spherical BLT nanocrystals after an in situ crystallization at 600 °C for 8 h. It has been found that the BLT gel particles can be obtained via a moderate sol–gel reaction inside the miniemulsion droplets at 65 °C, but their morphology and aggregation degree are strongly affected by the relative amounts of Span-80 and n-butanol. The perfect spherical BLT gel particles with no aggregation can be achieved only under the condition of 3 wt% n-butanol relative to the mass of cyclohexane, with excessive amount of n-butanol leading to the formation of ill-gelled particles with irregular shapes, while insufficient addition of n-butanol resulting in terrible aggregation of gel particles. To understand the formation of aggregation-free spherical BLT gel particles, a tentative mechanism is proposed and discussed, which reveals that a well-coordinated oil–water interfacial film made up of Span-80 and n-butanol molecules and the appropriately enhanced evaporation of water from such interfaces should be responsible for the formation of aggregation-free spherical BLT gel particles.

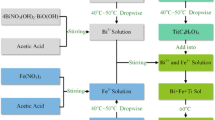

Graphical Abstract

Aggregation-free spherical BLT (Bi3.25La0.75Ti3O12) gel particles can be prepared from an effective inverse miniemulsion sol–gel process, and subsequently topotactically transformed into spherical BLT nanocrystals through an in situ crystallization.

Similar content being viewed by others

Introduction

Lanthanum-doped bismuth titanate (Bi3.25La0.75Ti3O12, BLT) is a typical Aurivillius bismuth-layered perovskite ferroelectric, structurally composed of alternating one (Bi2O2)2+ layer and three (Bi2Ti3O10)2− layers along the c-axis (Dorrian et al. 1972; Shimakawa et al. 2001; Chu et al. 2004), and La prefers to substitute for Bi in the perovskite-layer position (Wolfe and Newnham 1969). Compared to Bi4Ti3O12, Bi3.25La0.75Ti3O12 shows excellent dynamic characteristics during its alternating polarizations, such as high switching speed and fatigue resistance, and then has found potential applications in nonvolatile ferroelectric random-access memories (FeRAM) (Park et al. 1999; Lee et al. 2002; Kingon 1999; Nuraje and Su 2013). Over the past decade, the synthesis of BLT or Bi4Ti3O12 nanocrystals with regular morphologies has attracted an increasing research interest and many methods have been explored, such as wet no-coprecipitation chemistry (Lisoni et al. 2001), microemulsion assisted sol–gel process (Hou et al. 2010), hydrothermal route (Wang et al. 2013), electrospinning (Hou et al. 2013), hydrolysis method (Kan et al. 2004), and nanoscale solid-state reactive diffusion (Buscaglia et al. 2011). However, it is still in difficulty to synthesize cuboid or spherical BLT nanocrystals since the BLT strongly tends to grow into plate-like nanocrystals due to its much higher growth rates in the a- and b-axis directions than that along the c-axis in layered perovskite structure. In this case, moreover, the spontaneous polarization can occur along the direction almost parallel to the substrate in a self-assembled array structure of these plate-like nanocrystals, which obviously fails to satisfy the structural requirements by FeRAM (Wu et al. 2000; Chon et al. 2002; Bae et al. 2005; Yamada et al. 2013).

To avoid the highly anisotropic growth of BLT nanocrystals, a miniemulsion-based sol–gel approach for the synthesis of spherical BLT nanocrystals has been recently explored (Han et al. 2014), by which the sol–gel process is confined inside the miniemulsion droplets. The advantages of this method should include (1) the material available for the synthesis of every particle is restricted to the amount contained in droplets, which then determines the final size of individual particles; (2) the morphology of droplets may be one-to-one copied to the final gel particles during the sol–gel process inside individual droplets. However, the research has shown that although the anisotropic growth of BLT nanocrystals can be avoided by this method, the gel particles obtained after sol–gel process were often found easy to terribly adhere to each other due to the leaking of gelatinous substance from the miniemulsion droplets and thus hard to be transformed into well-dispersed spherical nanocrystals for self-assembly by in situ crystallization. Therefore, the synthesis of high-quality spherical perovskite BLT nanocrystals remains a challenge.

In this paper, we report our latest work on a novel miniemulsion sol–gel approach for the synthesis of highly dispersed and aggregation-free BLT gel spheres, by which the micro-droplets can be stabilized with Span-80 as surfactant and, especially, prevented from spontaneous aggregation by using n-butanol as co-surfactant, while the gelling network structure is formed. The as-obtained spherical BLT gel particles could be conveniently spread on Si-substrates and then topotactically transformed into highly dispersed spherical BLT nanocrystals via a mild thermal treatment. In addition, we elucidate the key roles of n-butanol in controlling the adhesion between the gel particles and propose a tentative mechanism governing the formation of highly dispersed spherical BLT gel spheres with no aggregation. The effect of heating rate and temperature-holding time on the morphology of final BLT nanocrystals is also discussed. This miniemulsion sol–gel approach is expected to be universally suitable for the preparation of other oxide gel particles for regular-shaped functional nanocrystals with high dispersibility.

Experimental

Materials

Tetrabutyl titanate (Ti(C4H9O)4, CP, Shanghai Lingfeng Chemical Reagent Co. Ltd), concentrated ammonia solution (NH3·H2O, 25–28 wt%, Shanghai Lingfeng Chemical Reagent Co. Ltd), bismuth oxide (Bi2O3, AR, Wenzhou Chemical Reagent Co. Ltd), lanthanum oxide (La2O3, 4 N, Sinopharm Chemical Reagent Co. Ltd), concentrated nitric acid (HNO3, 65–68 wt%, Shanghai Lingfeng Chemical Reagent Co. Ltd), hydrogen peroxide solution (H2O2, ≥30 wt%, Sinopharm Chemical Reagent Co. Ltd), cyclohexane (C6H12, AR, Shanghai Shenbo Chemical Reagent Co. Ltd.), Span-80 (C24H44O6, CP, Sinopharm Chemical Reagent Co. Ltd), and n-butanol (C4H9OH, AR, Shanghai Shenbo Chemical Reagent Co. Ltd) were used without further purification.

BLT precursor solution

According to the stoichiometry of Bi3.25La0.75Ti3O12, an aqueous solution of (Bi, La)(NO3)3 was prepared by dissolving 1.6920 g of Bi2O3 and 0.2732 g of La2O3 in 5 mL of nitric acid solution containing 1.58 mL of deionized water and 3.42 mL of concentrated nitric acid (65–68 wt%). Then, 0.23 mL tetrabutyl titanate (Ti(C4H9O)4) was slowly added to 23 mL of ammonia solution prepared by 20 mL of deionized water and 3 mL concentrated ammonia (25–28 wt%) to obtain Ti(OH)4 precipitate. Afterwards, the precipitate was washed three times with deionized water and introduced into 0.1 mL of hydrogen peroxide to prepare the peroxo-titanic acid solution, which was finally mixed with 0.5 mL of (Bi, La)(NO3)3 solution to achieve a redish BLT precursor solution.

Inverse miniemulsion and gelation in droplets

Figure 1 presents a schematic for the preparation of inverse miniemulsions and gel spheres. 3 wt% of Span-80 and 0–5 wt% of n-butanol relative to the mass of cyclohexane were dissolved in 40 mL of cyclohexane. Then, 0.6 mL of the previously prepared BLT precursor solution was added under strong magnetic stirring to obtain the crude emulsion. It was further treated in an ice bath by ultrasonication with Scientz JY92-IIN sonicator working in a pulse mode of 2/2 s and peak power 200 W for 20 min under vigorous magnetic stirring to achieve a desired homogeneous inverse miniemulsion. Subsequently, the as-prepared miniemulsion was transferred to a 50-mL three-necked and round-bottomed flask, which was then placed in a thermostat water bath at 65 °C for 48 h to prompt the gelling reactions of BLT precursor solution within the microdroplets in the miniemulsion. In the meanwhile, the miniemulsion, under a mechanical stirring at 180 rpm, was purged with nitrogen gas at 5 mL/min to timely take out the water vapor and served with a steady supplement of cyclohexane for its loss.

BLT gel particles and their crystallization

The BLT gel particles obtained in cyclohexane suspension after water-bathing at 65 °C for 48 h were separated and washed by three-cycle centrifugation (5000 rpm, 5 min) and re-dispersion in fresh cyclohexane. After another arrangement of three-cycle centrifugation and re-dispersion in ethanol, the gel particles were transferred on Si-substrates and dried in a DHG-9070A drying oven at 60 °C for 3 h. Afterwards, the samples were heated in air to 600 °C at different heating rates (1–10 °C min−1) and then kept at this temperature for different times (4–8 h) to effectuate the transformation of the gel particles into BLT nanocrystals.

Characterizations

The morphology, size, and microstructural details of BLT gel particles and nanocrystals were characterized by field-emission scanning electron microscopy with an energy-dispersive X-ray analyzer (FESEM, S-4800, Hitachi, Japan, accelerating voltage = 5 kV) and high-resolution transmission electron microscopy (HRTEM, JEM-200CX, JEOL, Japan, accelerating voltage = 200 kV). To trace the structural changes during the topotactic crystallization of BLT gel spheres, Fourier transform infrared spectroscopy (FT-IR, Nexus 670, 500–4000 cm−1), thermogravimetry, and differential scanning calorimetry (TG-DSC, STA449C, heating rate = 10 °C/min, air atmosphere), as well as X-ray diffractometry (XRD, Smart Lab, 40 kV/30 mA, = 1.5418 Å/Cu-Kα, 2 = 20°–70°, incident slit = 1/4°, receiving slits #1/#2 = 8/20 mm, scan mode = 2θ/θ, scan speed = 10°/min), were employed.

Results and discussion

Stability of inverse miniemulsions

It is well known that Span-80 is frequently used as a surfactant to stabilize droplets in inverse miniemulsions due to its long molecular chain and low hydrophilic–lipophilic balance index (HLB = 4.3) (Wang et al. 2010). However, using Span-80 alone has been shown not to help prevent the gel particles from terrible aggregation despite the fact that it can greatly improve the static stability of the present miniemulsion system (Han et al. 2014). Thus, a strategy of using small molecules as co-surfactant has been taken to coordinate the oil–water interface structures. Generally, in oil–water systems, short straight-chain alcohols (below C3) mostly tend to distribute in the water phase, while the long straight-chain alcohols (above C5) are apt to distribute in the oil phase (Baviere et al. 1981; Strey and Jonströmer 1992). Therefore, n-butanol is selected and used as co-surfactant in our experiments because it has a straight chain with four carbon atoms and preferentially distributes at oil–water interface for its balanced hydrophilic-lipophilic index (HLB = 7) (Bos and Van Vliet 2001). To establish an inverse miniemulsion suitable for preparing spherical BLT gel particles without aggregation, the static stability of the inverse miniemulsions with 3 wt% of Span-80 and different amounts of n-butanol (0–5 wt%) relative to the mass of cyclohexane phase was first investigated. Figure 2 shows the diagrams of the miniemulsion homogeneity versus standing time at room temperature in the cases with different amounts of n-butanol. It was quantitatively estimated by measuring the relative height of the top translucent liquid column, as schematically shown in Fig. 2.

It can be seen that the addition of n-butanol shows a significant influence on the stability of the BLT miniemulsions, while the same amount of Span-80 is used. When Span-80 is used alone, the inverse miniemulsion cannot lose its stability until the standing time is increased to 72 h (Fig. 2a). However, the miniemulsion may stay homogeneous for 20 h when 2 wt% of n-butanol is used together with Span-80 (Fig. 2c). After further increasing the amount of n-butanol to 3 wt%, the time of keeping the miniemulsion homogeneous sharply decreases to 3 h (Fig. 2d). When the amount of n-butanol is increased to 5 wt%, the miniemulsion can keep its homogeneity for only 1h. This result clearly implies that the stability of BLT inverse miniemulsion is very sensitive to the presence of n-butanol.

According to the principles of colloidal chemistry, in a stable miniemulsion, the dispersed droplets must be stabilized against both the Ostwald ripening driven by Laplace pressure and the sedimentation driven by gravity force. In our experiments, the concerned miniemulsion should be partially stabilized with respect to the Ostwald ripening process because the Laplace pressure is mostly counterbalanced by osmotic pressure built up from the high concentration of metal ions inside the droplets (Landfester et al. 2000). Therefore, in this case, the steric stability of dispersed droplets against flocculating sedimentation should become the main stability mechanism. Considering the long hydrophobic molecular chains that may freely stretch into oil phase, it is believed that Span-80 molecules densely assembled at the oil–water interface can supply a good steric stability for BLT aqueous droplets dispersed in the phase of cyclohexane, as suggested in the literature (Bourrel et al. 1980; Ushikubo and Cunha 2014). However, as the addition of small n-butanol molecules, the effective concentration of Span-80 at oil–water interface is believed to be remarkably decreased since the n-butanol molecules with higher HLB index tend to be located at the interface by partially replacing Span-80. As a result, less Span-80 molecules are accommodated at the interface, which might lead to the increased possibility of flocculation and then to the poorer stability against sedimentation since n-butanol molecules have no steric hindrance effect (Leal-Calderon et al. 1996). Therefore, it can be concluded that the reduced stability of BLT inverse miniemulsion should be mainly caused by flocculating sedimentation, which may be enhanced by increasing the amount of n-butanol.

Formation of BLT gel particles

To explore the influence of n-butanol on the aggregation states of BLT gel particles and their shape-developments, sol–gel reactions were arranged in the droplets dispersed in the miniemulsion prepared with different amounts of n-butanol (0–5 wt%) for comparison. Figure 3 shows the typical shapes and aggregation states of the BLT gel particles obtained at different amounts of n-butanol. It can be noted that with no addition of n-butanol, lumpy aggregates of BLT gel particles were formed (Fig. 3a). Moreover, the particles have lost their parent droplet’s spherical shape and are apparently cemented by sticky substance. By introducing 1–2 wt% of n-butanol relative to the mass of cyclohexane phase, the aggregation severity of BLT gel particles is conspicuously reduced (Fig. 3b), and a considerable amount of the particles are separated to one another with quasi-spherical shape (Fig. 3c). When 3 wt% of n-butanol is added, the highly dispersed spherical BLT gel particles with an average size of 150 nm are successfully obtained (Fig. 3d). More interestingly, by further increasing the amount of n-butanol to 4–5 wt%, the obtained gel particles are well dispersed but show wizened- or shriveled-spherical morphologies (Fig. 3e, f).

In view of the above experimental results and the fact that the addition of n-butanol into the miniemulsion is actually unfavorable to the dispersion stability of BLT microdroplets, we believe that the specific interfacial structure made up of Span-80 and n-butanol molecules should be responsible for the formation of aggregation-free spherical BLT gel particles, instead of other factors such as favorable Zeta-potentials, which are often associated with the behavior of ionic surfactants (Allan and Mason 1961; Claesson et al. 2001). To understand such a particular interfacial structure and its influence on the development of BLT gel particles, we propose a tentative mechanism, as schematically shown in Fig. 4. When the amount of n-butanol was below 2 wt% (case 1 in Fig. 4), few of Span-80 molecules lodging at the oil–water interfacial film are supposed to be replaced by n-butanol molecules. In this case, on the one hand, the rate of gelling reactions inside the droplets is controlled by the low evaporation of water from the dispersed droplets due to the dense coverage of Span-80 molecules at the oil–water interface. The viscosity of the material inside droplets would be increased slowly from the beginning of condensation reaction, and, moreover, the dispersed droplets should keep such a slowly increasing viscosity for a long time before they can take shape individually. Obviously, this would greatly increase the collision number of droplets under gelatinization. On the other hand, the oil–water interfacial film composed almost only of Span-80 molecules is rather rigid (Santini et al. 2007) and would be vulnerable and easy to break during the dynamic collision of droplets due to their relatively large molecular size and poor mobility. The former characteristic may endow the miniemulsion with good dispersion stabilities by virtue of steric hindrance effect, while the latter will inevitably cause the leaking of the sticky substance from the collided droplets. As a consequence, the agglomerating possibility of the gelling particles can be quite high due to their large collision number and easy out-spilling of viscous substance when the amount of n-butanol is rather low.

By increasing the amount of n-butanol to 3 wt% (case 2 in Fig. 4), the rigid interfacial structure built up by Span-80 molecules is expected to be favorably modified by n-butanol molecules. The large Span-80 molecules with low HLB index and small n-butanol molecules with large HLB index are supposed to coordinately construct a more dense, elastic, and tough oil–water interfacial film (Leung and Shah 1987; Penders and Strey 1995; Hou and Shah 1987), which is enabled to prevent the interface from breaking since a sufficient amount of n-butanol molecules with high mobility may quickly restore the balanced concentration distribution of surfactant molecules at the interface from the chaos due to the dynamic collision and, then, eliminate the leaking probability of sticky substance from the droplets. In addition, the evaporation of water from the oil–water interface is expected to be effectively enhanced because the addition of n-butanol molecules into water may significantly increase its vapor pressure (Stockhardt and Hull 1931). Evidently, this effect helps accelerate the condensation reaction inside the droplets and, accordingly, reduce the period of time, in which the collided gel particles may be cemented or stuck together if the gelling material are spilled out by collision. In other words, the collision number or aggregation probability of droplets is thus reduced. Therefore, no spilling of the gelling material out of the droplets due to the construction of a well-coordinated interfacial film of Span-80 and n-butanol molecules and a greatly reduced collision number of the droplets due to the enhanced evaporation of water are believed to be the decisive factors to ensure the realization of highly dispersed BLT gel spheres.

With further increasing the amount of n-butanol to above 3 wt% (case 3 in Fig. 4), a considerable amount of Span-80 molecules at the oil–water interfacial film should be replaced by n-butanol molecules. In this case, it is expected that a fast evaporation of water from the dispersed droplets may take place due to the increased vapor pressure of water, as discussed in the previous section. Moreover, this process may even bring the system in such a condition that the water evaporation is carried out at a rate higher than that for the condensation reactions for gelling, and finally, some species in the droplets are forced to precipitate out as their concentrations quickly reach their oversaturation levels. Obviously, this understanding can well account for the appearance of wizened-spherical or irregular gel particles when the added amount of n-butanol is over 3 wt%.

FT-IR and TG-DSC analysis of BLT gel spheres

Figure 5 shows a typical FT-IR spectrum of the BLT gel spheres obtained after drying at 60 °C for 3 h. It can be seen that there are some characteristic bands, which correspond to the different functional groups that can be present in BLT gel particles. The peaks in the range of 3500–3000 cm−1 should be assigned to the characteristic stretching vibration of free water, i.e., the stretching vibrations of hydroxyl groups. The peaks that are located at 2927 and 1296 cm−1 could be ascribed to the vibrations of functional groups –CH and –CH2, respectively, which should belong to Span-80 molecules, and then suggests that there is a small amount of Span-80 remaining on the surface of BLT gel spheres. As to the peak appearing at 1625 cm−1, it should arise from the residual nitrate ions. Then, the peaks at 1392 and 1033 cm−1 are believed to be associated with the stretching vibrations of Ti–OOH and Ti–OH, which prove the formation of 3-dimensional networks in the gel spheres (Gu et al. 1998; Hardy et al. 2005; Hardy et al. 2003).

With the purpose of preparing phase-pure BLT nanocrystals, thermal analysis of BLT gel spheres was carried out so as to explore what is happening with the sample under the thermal treatments. Figure 6 gives the typical TG-DSC curves for the BLT gel spheres in air at a heating rate of 10 °C/min. It is observed from TG curve that the weight loss of BLT gel spheres takes place in three steps from room temperature to 550 °C. The first step, from 38.9 to 300 °C, amounts to a weight loss of 27.4 wt%, which is accompanied by an endothermic peak and two exothermic peaks in DSC curve. It suggests the evaporation of residual water and the decomposition of organic substances (surfactants). The second step appears to happen from 300 to 500 °C with a weight loss of 2.4 wt% and two exothermic peaks, which may be ascribed to the pyrolysis of remanent nitrate (Klingenberg and Vannice 1996) and is in agreement with the FT-IR results. The third step can be observed from 500 to 550 °C, with a weight loss of 4.6 wt% and one exothermic peak, which is believed to arise from the crystallization of amorphous BLT gel spheres.

Topotactic crystallization of BLT gel spheres

To topotactically transform the BLT gel particles into spherical nanocrystals, a designed annealing treatment for the gel spheres was carried out. Figure 7a shows the XRD patterns of BLT gel spheres annealed at 600 °C for 4 and 8 h, respectively, in comparison with the diffraction diagram of BLT gel spheres. It can be seen that no diffraction peaks can be observed in the XRD pattern of BLT gel spheres without any thermal treatments. After annealing of the sample at 600 °C for 4 h, the crystalline phase BLT starts to appear with Bi2Ti2O7 as second phase, while the single-phase BLT can be found by extending annealing time to 8 h, with all the X-ray diffraction peaks in a good agreement with those for the orthorhombic structure of Bi4Ti3O12 (JCPDS No. 35-0795). With the help of software Jade 5.0, the XRD data of the sample annealed at 600 °C for 8 h were analyzed to obtain the lattice parameters: a = 5.435, b = 32.873, and c = 5.429, which are consistent with the data reported in the literature (Su et al. 2007; Lee et al. 2002; Chon et al. 2001) and confirm the formation of single-phase Bi3.25La0.75Ti3O12. In the meanwhile, the average grain size of BLT nanocrystals formed in the course of annealing at 600 °C for 8 h was also estimated by using Scherrer formula at 91.2 nm.

To check the chemical composition of as-obtained BLT nanocrystals, the energy-dispersive X-ray spectroscopy (EDS) was performed with the result shown in Fig. 7b. It can be noted that the BLT nanocrystals contain no impurities other than the constituent elements Bi, La, Ti, and O with their atomic percentages being 16.81, 3.84, 14.97, and 64.38, respectively, which are very close to the stoichiometric values of Bi3.25La0.75Ti3O12.

Figure 8 presents the SEM images of BLT nanocrystals, transformed from the BLT gel particles after annealing at 600 °C for 8 h at different heating rates. Apparently, it can be observed that BLT nanocrystals inherit the high dispersibility of their parent gel spheres after the heat treatments. However, some fissures and pits can be seen at the surface of spherical BLT nanocrystals obtained after annealing treatments at the heating rates of 10 °C/min (Fig. 8a) and 5 °C/min (Fig. 8b), whereas they are greatly reduced either in number or in size as the heating rate is cut down and then almost disappear when the heating rate is decreased to 1 °C/min (Fig. 8c). This result clearly indicates that the defects on the surface of BLT nanocrystals are most probably caused by the burst decomposition of residual organics in the green gel particles, and a gentle heating process is believed to favor the formation of spherical BLT nanocrystals with smooth surface. Besides, the particle sizes based on a typical SEM image for BLT nanocrystals obtained after annealing at 600 °C for 8 h were statistically measured by using software Nano Measurer 1.2, leading to an average size of 120 nm. Compared to this value, the smaller grain size estimated by XRD (~91 nm) is believed to arise mainly from the negative deviation caused by Scherrer formula when large grains (>100 nm) are involved and the errors from the limited statistics by SEM image.

Figure 9 demonstrates the high-resolution transmission electron (HRTEM) image of a typical spherical BLT nanocrystal, as pointed by a red arrow in Fig. 8c, and its electron diffraction (ED) pattern. The inset in Fig. 9a gives the fast Fourier transform (FFT) pattern of the corresponding lattice fringes. Evidently, the clear lattice fringes indicate that BLT nanocrystals are well crystallized, and the corresponding interplanar distance of the lattice is 0.1739 nm, which should be ascribed to the (311) planes of the orthorhombic structure of BLT. As to the electron diffraction (ED) pattern by a single spherical BLT nanocrystals (Fig. 9b), it further demonstrates the high crystallinity and coherent crystalline structure of the individual BLT nanocrystals.

HRTEM image of a typical spherical BLT nanocrystal, as marked by a red arrow in Fig. 8c, and its electron diffraction (ED) pattern, with the inset showing the corresponding FFT pattern

Conclusions

In summary, aggregation-free spherical BLT (Bi3.25La0.75Ti3O12) gel particles with an average size of about 150 nm have been successfully prepared via an inverse miniemulsion sol–gel approach using cyclohexane as continuous phase and submicro-droplets with aqueous solution containing Bi3+, La3+, and Ti4+ ions as dispersed phase when the appropriate amounts of Span-80 and n-butanol, as surfactant and co-surfactant, are utilized. The perfect spherical BLT gel particles with no aggregation may be achieved under the conditions of 3 wt% of Span-80 plus 3 wt% of n-butanol relative to the mass of cyclohexane, with excessive amount of n-butanol leading to the particles with irregular morphology, while the shortage in n-butanol provoking the terrible aggregation of the gel particles. The as-obtained spherical BLT gel particles can be topotactically transformed into spherical BLT nanocrystals through an in situ crystallization at 600 °C, which show high crystallinity and coherent crystalline structure.

The mechanical study has revealed that the particular oil–water interfacial structure made up of Span-80 and n-butanol molecules should be first responsible for the formation of aggregation-free spherical BLT gel particles. The large Span-80 molecules with low HLB index and small n-butanol molecules with large HLB index would coordinately construct a more dense, elastic, and tough oil–water interfacial film, which may greatly reduce the leaking probability of sticky substance from the droplets while they are collided. In addition, the incorporation of n-butanol molecules into the interfacial films may significantly increase the vapor pressure of water. This effect helps accelerate the condensation reaction inside the droplets and, accordingly, reduce their aggregation probability.

References

Allan RS, Mason SG (1972) Effects of electric fields on coalescence in liquid + liquid systems. Trans Faraday Soc 57:2027–2040. doi:10.1039/tf9615702027

Bae JC, Kim SS, Choi EK, Song TK, Kim WJ, Lee YI (2001) Ferroelectric properties of lanthanum-doped bismuth titanate thin films grown by a sol–gel method. Thin Solid Films 472:90–95. doi:10.1016/j.tsf.2004.06.115

Baviere M, Schechter R, Wade W (2004) The influence of alcohols on microemulsion composition. J Colloid Interface Sci 81:266–279. doi:10.1016/0021-9797(81)90322-2

Bos MA, Van Vliet T (1969) Interfacial rheological properties of adsorbed protein layers and surfactants: a review. Adv Colloid Interface Sci 91:437–471. doi:10.1016/s0001-8686(00)00077-4

Bourrel M, Salager JL, Schechter RS, Wade WH (1999) A correlation for phase behavior of nonionic surfactants. J Colloid Interface Sci 75:451–461. doi:10.1016/0021-9797(80)90470-1

Buscaglia MT, Sennour M, Buscaglia V, Bottino C, Kalyani V, Nanni P (2002) Formation of Bi4Ti3O12 one-dimensional structures by solid-state reactive diffusion. From core–shell templates to nanorods and nanotubes. Cryst Growth Des 11:1394–1401. doi:10.1021/cg101697r

Chon U, Jang HM, Lee SH, Yi GC (1999) Formation and characteristics of highly c-axis-oriented Bi3.25La0.75Ti3O12 thin films on SiO2/Si (100) and Pt/Ti/SiO2/Si (100) substrates. J Mater Res 16:3124–3132. doi:10.1557/JMR.2001.0431

Chon U, Jang HM, Kim MG, Chang CH (2013) Layered perovskites with giant spontaneous polarizations for nonvolatile memories. Phys Rev Lett 89:087601. doi:10.1103/physrevlett.89.087601

Chu MW, Caldes MT, Brohan L, Ganne M, Marie AM, Joubert O, Piffard Y (2001) Bulk and surface structures of the Aurivillius phases: Bi4−xLaxTi3O12 (0 ≤ x ≤ 2.00). Chem Mater 16:31–42. doi:10.1021/cm030341m

Claesson PM, Blomberg E, Poptoshev E (2001) Surface forces and emulsion stability. Marcel Dekker, New York, pp 305–326. doi: 10.1201/9781420029581.ch13

Dorrian JF, Newnhama RE, Smitha DK, Kay MI (2013) Crystal structure of Bi4Ti3O12. Ferroelectrics 3:17–27. doi:10.1080/00150197108237680

Gu H, Chen P, Zhou Y, Zhao M, Kuang A, Li X (2013) Reactions in preparing Bi4Ti3O12 ultrafine powders by sol–gel process. Ferroelectrics 211:271–280. doi:10.1080/00150199808232348

Han L, Zheng L, Hu Z, Yin S, Zeng Y (2004) Preparation of spherical Bi3.25La0.75Ti3O12 nanocrystals by a sol–gel inverse mini-emulsion approach. Electron Mater Lett 10:1–4. doi:10.1007/s13391-013-3064-8

Hardy A, Van Werde K, Vanhoyland G, Van Bael MK, Mullens J, Van Poucke LC (2011) Study of the decomposition of an aqueous metal-chelate gel precursor for (Bi, La)4Ti3O12 by means of TGA-FTIR, TGA-MS and HT-DRIFT. Thermochim Acta 397:143–153. doi:10.1016/s0040-6031(02)00272-1

Hardy A, Vanhoyland G, Geuzens E, Van Bael MK, Mullens J, Van Poucke LC, D’Haen J (2000) Gel structure, gel decomposition and phase formation mechanisms in the aqueous solution-gel route to lanthanum substituted bismuth titanate. J Sol-Gel Sci Technol 33:283–298. doi:10.1007/s10971-005-6378-7

Hou MJ, Shah DO (2002) Effects of the molecular structure of the interface and continuous phase on solubilization of water in water/oil microemulsions. Langmuir 3:1086–1096. doi:10.1021/la00078a036

Hou J, Qu Y, Krsmanovic D, Kumar RV (2005) Peroxide-based route assisted with inverse microemulsion process to well-dispersed Bi4Ti3O12 nanocrystals. J Nanopart Res 12:1797–1805. doi:10.1007/s11051-009-9737-4

Hou D, Luo W, Huang Y, Jimmy CY, Hu X (2013) Synthesis of porous Bi4Ti3O12 nanofibers by electrospinning and their enhanced visible-light-driven photocatalytic properties. Nanoscale 5:2028–2035. doi:10.1039/c2nr33750a

Kan Y, Jin X, Zhang G, Wang P, Cheng YB, Yan D (2014) Lanthanum modified bismuth titanate prepared by a hydrolysis method. J Mater Chem 14:3566–3570. doi:10.1039/b408149h

Kingon A (2010) Device physics: memories are made of … Nature 401:658–659. doi:10.1038/44307

Klingenberg B, Vannice MA (1981) Influence of pretreatment on lanthanum nitrate, carbonate, and oxide powders. Chem Mater 8:2755–2768. doi:10.1021/cm9602555

Landfester K, Willert M, Antonietti M (1992) Preparation of polymer particles in nonaqueous direct and inverse miniemulsions. Macromolecules 33:2370–2376. doi:10.1021/ma991782n

Leal-Calderon F, Gerhardi B, Espert A, Brossard F, Alard V, Tranchant JF, Stora T, Bibette J (2001) Aggregation phenomena in water-in-oil emulsions. Langmuir 12:872–874. doi:10.1021/la950615n

Lee HN, Hesse D, Zakharov N, Gösele U (2000) Ferroelectric Bi3. 25La0. 75Ti3O12 films of uniform a-axis orientation on silicon substrates. Science 296:2006–2009. doi:10.1126/science.1069958

Leung R, Shah DO (1980) Solubilization and phase equilibria of water-in-oil microemulsions: II. Effects of alcohols, oils, and salinity on single-chain surfactant systems. J Colloid Interface Sci 120:330–344. doi:10.1016/0021-9797(87)90360-2

Lisoni JG, Millán P, Vila E, Martín de Vidales JL, Hoffmann T, Castro A (2014) Synthesis of ferroelectric Bi4Ti3O12 by alternative routes: wet no-coprecipitation chemistry and mechanochemical activation. Chem Mater 13:2084–2091. doi:10.1021/cm000944n

Nuraje N, Su K (1996) Perovskite ferroelectric nanomaterials. Nanoscale 5:8752–8780. doi:10.1039/c3nr02543h

Park BH, Kang BS, Bu SD, Noh TW, Lee J, Jo W (1961) Lanthanum-substituted bismuth titanate for use in non-volatile memories. Nature 401:682–684. doi:10.1038/44352

Penders MHGM, Strey R (2001) Phase behavior of the quaternary system H2O/n-octane/C8E5/n-octanol: role of the alcohol in microemulsions. J Phys Chem 99:10313–10318. doi:10.1021/j100025a037

Santini E, Liggieri L, Sacca L, Clausse D, Ravera F (2007) Interfacial rheology of Span 80 adsorbed layers at paraffin oil-water interface and correlation with the corresponding emulsion properties. Colloids Surf A 309:270–279. doi:10.1016/j.colsurfa.2006.11.041

Shimakawa Y, Kubo Y, Tauchi Y, Asano H, Kamiyama T, Izumi F, Hiroi Z (1987) Crystal and electronic structures of Bi4-xLaxTi3O12 ferroelectric materials. Appl Phys Lett 79:2791–2793. doi:10.1063/1.1410877

Stockhardt JS, Hull CM (1995) Vapor–liquid equilibria and boiling-point composition relations for systems n-butanol–water and isobutanol–Water 1, 2. Ind Eng Chem 23:1438–1440. doi:10.1021/ie50264a034

Strey R, Jonströmer M (1987) Role of medium-chain alcohols in interfacial films of nonionic microemulsions. J Phys Chem 96:4537–4542. doi:10.1021/j100190a075

Su JK, Moriyoshi C, Kimura S, Kuroiwa Y (1931) Direct observation of oxygen stabilization in layered ferroelectric Bi3.25La0.75Ti3O12. Appl Phys Lett 91:062913. doi:10.1063/1.2768906

Ushikubo FY, Cunha RL (1998) Stability mechanisms of liquid water-in-oil emulsions. Food Hydrocoll 34:145–153. doi:10.1016/j.foodhyd.2012.11.016

Wang J, Yang F, Tan J, Liu GP, Xu J, Sun DJ (2005) Pickering emulsions stabilized by a lipophilic surfactant and hydrophilic platelike particles. Langmuir 26:5397–5404. doi:10.1021/la903817b

Wang F, Wang J, Zhong X, Li B, Liu J, Wu D, Mo D, Guo D, Yuan S, Zhang K, Zhou Y (2003) Shape-controlled hydrothermal synthesis of ferroelectric Bi4Ti3O12 nanostructures. CrystEngComm 15:1397–1403. doi:10.1039/c2ce26330k

Wolfe RW, Newnham RE (1996) Rare earth bismuth titanates. J Electrochem Soc 116:832–835. doi:10.1149/1.2412072

Wu D, Li A, Zhu T, Liu Z, Ming N (2007) Ferroelectric properties of Bi3.25La0.75Ti3O12 thin films prepared by chemical solution deposition. J Appl Phys 88:5941–5945. doi:10.1063/1.1322387

Yamada T, Shibata T, Ishii K, Kimura J, Funakubo H, Yoshino M, Nagasaki T (2013) Bi4Ti3O12 Nanowall growth driven by anisotropic growth rate and size control. Jpn J Appl Phys 52: 09KA09. doi: 10.7567/jjap.52.09ka09

Acknowledgments

The authors would like to gratefully acknowledge the funds from the Priority Academic Development Program of Jiangsu Higher Education Institutions, P. R. China, and the Program for Changjiang Scholars and Innovative Research Teams in Universities (PCSIRT), IRT1146, of P. R. China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, A., Zeng, Y., Han, L. et al. Highly dispersed spherical Bi3.25La0.75Ti3O12 nanocrystals via topotactic crystallization of aggregation-free gel particles from an effective inverse miniemulsion sol–gel approach. J Nanopart Res 17, 369 (2015). https://doi.org/10.1007/s11051-015-3180-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3180-5