Abstract

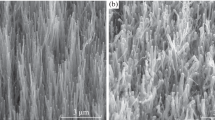

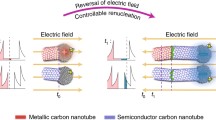

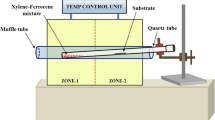

Ordered arrays of carbon nanotubes (CNT) have been coated by Ni nanoparticles and Ni thin films by using the chronoamperometry technique for nickel reduction. Two different kinds of nanotube arrays have been used: aligned bundles of CNT grown on Si substrates by chemical vapour deposition (CVD) and networks of CNT bundles positioned via a dielectrophoretic post-synthesis process between the electrodes of a multifinger device. The morphology and structure of the Ni-coated CNT bundles have been characterized by field emission scanning electron microscopy (FE-SEM) and X-ray diffraction (XRD). By changing the parameters of the electrochemical process, it is possible to modulate the morphological characteristics of the Ni deposits, which can be obtained in form of nanoparticles uniformly distributed along the whole length of the CNT bundles or of Ni thin films. A qualitative study of the nucleation and growth mechanism of Ni onto CNT has been performed using the theoretical model for diffusion-controlled electrocrystallization, and a correlation between growth mechanism and samples morphology is presented and discussed. The possibility to maintain the architecture of the pristine nanotube deposits after the Ni coating process opens new perspectives for integration of CNT/Ni systems in magnetic and spintronics devices.

Similar content being viewed by others

References

Abyaneh MY, Fleischmann M (1981) The electrocrystallisation of nickel. Part II. Comparison of models with the experimental data. J Electroanal Chem 119(1):197–208

Abyaneh MY, Fleischmann M (2002a) Extracting nucleation rates from current-time transients: comments on the criticisms of Fletcher on three papers published in this issue. J Electroanal Chem 530(1–2):108–118

Abyaneh MY, Fleischmann M (2002b) Extracting nucleation rates from current-time transients: Further comments. J Electroanal Chem 530(1–2):123–125

Ang LM, Hor TSA, Xu GQ, Tung CH, Zhao SP, Wang JLS (2000) Decoration of activated carbon nanotubes with copper and nickel. Carbon 38(3):363–372

Arai S, Endo M, Kaneko N (2004) Ni-deposited multi-walled carbon nanotubes by electrodeposition. Carbon 42(3):641–644

Ayala P, Freire FL Jr, Gu L, Smith DJ, Solórzano IG, Macedo DW, Sande JBV, Terrones H, Rodriguez-Manzo J, Terrones M (2006) Decorating carbon nanotubes with nanostructured nickel particles via chemical methods. Chem Phys Lett 431(1–3):104–109

Bittencourt C, Felten A, Ghijsen J, Pireaux JJ, Drube W, Erni R, Van Tendeloo G (2007) Decorating carbon nanotubes with nickel nanoparticles. Chem Phys Lett 436(4–6):368–372

Budevski E, Staikov G, Lorenz WJ (1996) Electrochemical phase formation and growth: an introduction to the initial stages of metal deposition. Wiley-VCH, Verlag GmbH, Weinheim

Chen XH, Cheng FQ, Li SL, Zhou LP, Li DY (2002) Electrodeposited nickel composites containing carbon nanotubes. Surf Coat Technol 155(2–3):274–278

Chen XH, Chen CS, Xiao HN, Cheng FQ, Zhang G, Yi GJ (2005) Corrosion behavior of carbon nanotubes-Ni composite coating. Surf Coat Technol 191(2–3):351–356

Cheng J, Zhang X, Ye Y (2006) Synthesis of nickel nanoparticles and carbon encapsulated nickel nanoparticles supported on carbon nanotubes. J Solid State Chem 179(1):91–95

Deo RP, Lawrence NS, Wang J (2004) Electrochemical detection of amino acids at carbon nanotube and nickel-carbon nanotube modified electrodes. Analyst 129(11):1076–1081

Fan Y, Goldsmith BR, Collins PG (2005) Identifying and counting point defects in carbon nanotubes. Nat Mater 4(12):906–911

Fletcher S (2002a) Extracting nucleation rates from current-time transients. Comments on three papers by Abyaneh and Fleischmann published in this issue. J Electroanal Chem 530(1–2):105–107

Fletcher S (2002b) Extracting nucleation rates from current-time transients. Concluding remarks. J Electroanal Chem 530(1–2):119–122

Hyde ME, Compton RG (2003) A review of the analysis of multiple nucleation with diffusion controlled growth. J Electroanal Chem 549(suppl):1–12

Jin GP, Ding YF, Zheng PP (2007) Electrodeposition of nickel nanoparticles on functional MWCNT surfaces for ethanol oxidation. J Power Sources 166(1):80–86

Krupke R, Hennrich F, Löhneysen H, Kappes MM (2003) Separation of metallic from semiconducting single-walled carbon nanotubes. Science 301(5631):344–347

Mann D, Javey A, Kong J, Wang Q, Dai H (2003) Ballistic transport in metallic nanotubes with reliable Pd ohmic contacts. Nano Lett 3(11):1541–1544

Orlanducci S, Sessa V, Terranova ML, Rossi M, Manno D (2003) Aligned arrays of carbon nanotubes: modulation of orientation and selected-area growth. Chem Phys Lett 367(1–2):109–115

Powder Diffraction File, Joint Committee on Powder Diffraction Standards, ASTM, Card 4-850

Scharifker BR, Hills GJ (1981) Electrochemical kinetics at microscopically small electrodes. J Electroanal Chem 130:81–97

Scharifker BR, Hills GJ (1983) Theoretical and experimental studies of multiple nucleation. Electrochim Acta 28(7):879–889

Shi L, Sun CF, Gao P, Zhou F, Liu WM (2006) Electrodeposition and characterization of Ni–Co–carbon nanotubes composite coatings. Surf Coat Technol 200(16–17):4870–4875

Terranova ML, Piccirillo S, Sessa V, Rossi M, Cappuccio G (1999) A new CVD route for the synthesis of composite diamond-based materials. Adv Mater 11(8):101–105

Terranova ML, Piccirillo S, Sessa V, Sbornicchia P, Rossi M, Botti S, Manno D (2000) Growth of single-walled carbon nanotubes by a novel technique using nanosized graphite as carbon source. Chem Phys Lett 327(5–6):284–290

Terranova ML, Lucci M, Orlanducci S, Tamburri E, Sessa V, Reale A, Di Carlo A (2007) Carbon nanotubes for gas detection: materials preparation and device assembly. J Phys Condens Matter 19(22):1–14; art no 225004

Tersoff J (2003) A barrier falls. Nature 424(6949):622–623

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tamburri, E., Toschi, F., Guglielmotti, V. et al. Nanofabrication by electrochemical routes of Ni-coated ordered arrays of carbon nanotubes. J Nanopart Res 11, 1311–1319 (2009). https://doi.org/10.1007/s11051-008-9520-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-008-9520-y