Abstract

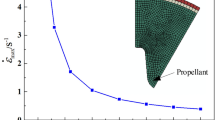

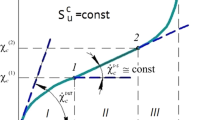

In this paper, the Weibull distribution function was used to describe the mechanical behavior of damage evolution and a new type of nonlinear viscoelastic constitutive model was established. Based on the results of a relaxation test and a uniaxial tensile test of NEPE propellant, the parameters of this model were fitted. The accuracy of the model was verified by comparing the predictive results and the experimental results. The UMAT subroutine was developed based on the Fortran code, and it was applied to simulate a uniaxial tensile model and a biaxial tensile model in ABAQUS. The finite-element calculated solutions are in good agreement with the experimental values, which proves that the subroutine is effective and the Mises equivalence criterion is applicable to NEPE solid propellant.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Barriere, T., Gabrion, X., Holopainen, S.: A compact constitutive model to describe the viscoelastic-plastic behaviour of glassy polymers: comparison with monotonic and cyclic experiments and state-of-the-art models. Int. J. Plast. 122, 31–48 (2019)

Boyce, M.C., Weber, G.G., Parks, D.M.: On the kinematics of finite strain plasticity. J. Mech. Phys. Solids 37, 647–665 (1989)

Chi, X., Peng, S., Zhang, F., et al.: Effects of aging on statistical mechanical properties distributions of NEPE propellant. J. Solid Rocket Technol. 42(3), 396–402 (2019)

Cui, H., Shen, Z., Li, H.: A new constitutive equation for solid propellant with the effects of aging and viscoelastic Poisson’s ratio. Meccanica 53, 2393–2410 (2018)

Dibenedetto, G.L., Vanramshorst, M.C.J., Duvalois, W., et al.: In-situ tensile testing of propellants in SEM: influence of temperature. Propellants Explos. Pyrotech. 42(12), 1396–1400 (2017)

Duncan, E.J.S., Margetson, J.: A nonlinear viscoelastic theory for solid rocket propellants based on a cumulative damage approach. Propellants Explos. Pyrotech. 23(2), 94–104 (1998)

Jung, G.D., Youn, S.K.: A nonlinear viscoelastic constitutive model of solid propellant. Int. J. Solids Struct. 36, 3755–3777 (1999)

Jung, G.D., Youn, S.K., Kim, B.K.: A three-dimensional nonlinear viscoelastic constitutive model of solid propellant. Int. J. Solids Struct. 37(34), 4715–4732 (2000)

Kumar, N., Patel, B.P., Venkateswara Rao, V., et al.: Hyperviscoelastic constitutive modelling of solid propellants with damage and compressibility. Propellants Explos. Pyrotech. 43(5), 461–471 (2018)

Laheru, K.L.: Development of a generalized failure criterion for viscoelastic materials. J. Propuls. Power 8(4), 756–759 (1992)

Lei, M., Wang, J., Cheng, J., et al.: A constitutive model of the solid propellants considering the interface strength and dewetting. Compos. Sci. Technol. 185, 107893 (2020)

Li, J.-m., Xue, Z., Li, W., et al.: Experimental study on tensile damage process of NEPE propellant. Chin. J. Energ. Mater. 17(02), 241–243 (2009)

Miller, T.C.: Damage and dilatometry for solid propellants with digital image correlation. Propellants Explos. Pyrotech. 44(2), 234–245 (2019)

OÈzuÈ pek, S., Becker, E.B.: Constitutive equations for solid propellants. J. Eng. Mater. Technol. 119(2), 125–132 (1997)

Park, S.: Development of a Nonlinear Viscoelastic Constitutive Equation for Particulate Composites with Growing Damage. University of Texas Press, Austin (1994)

Park, S.W., Schapery, R.A.: A viscoelastic constitutive model for particulate composites with growing damage. Int. J. Solids Struct. 34(8), 931–947 (1997)

Qiuqiu, Y., Cai, R., Xu, S., et al.: Damage behavior of GAP solid propellant by in-situ tensile SEM method. Chin. J. Explos. Propellants 42(5), 511–515 (2019)

Ramshorst, M.C.J., Benedetto, G.L., Duvalois, W., et al.: Investigation of the failure mechanism of HTPB/AP/Al propellant by in-situ uniaxial tensile experimentation in SEM. Propellants Explos. Pyrotech. 41(4), 700–708 (2016)

Schapery, R.A.: Nonlinear constitutive equations for solid propellant based on a work potential and micromechanical model. In: JANNAF Structures and Mechanical Behavior Subcommittee Meeting, Huntsville, March 17-19 (1987)

Schapery, R.A.: Analysis of damage growth in particulate composites using a work potential. Compos. Eng. 1(3), 167–182 (1991)

Schapery, R.A.: Nonlinear viscoelastic and viscoplastic constitutive equations with growing damage. Int. J. Fract. 97(1–4), 33–66 (1999)

Shen, T.: Cavitation damage model and life prediction of solid polymers. Chin. Sci. Bull. 46(11), 965–968 (2001)

Simo, J.C.: On a fully three-dimensional finite-strain viscoelastic damage model: formulation and computational aspects. Comput. Methods Appl. Mech. Eng. 60(2), 153–173 (1987)

Swanson, S.R., Christensen, L.W.: A constitutive formulation for high elongation propellant. J. Spacecr. Rockets 20, 559–566 (1983)

Tunç, B., Özüpek, Ş.: Implementation and validation of a three dimensional damaging finite strain viscoelastic model. Int. J. Solids Struct. 102(103), 275–285 (2016)

Xu, F., Aravas, N., Sofronis, P.: Constitutive modeling of solid propellant materials with evolving microstructural damage. J. Mech. Phys. Solids 56(5), 2050–2073 (2008)

Xu, J., Ju, Y., Han, B., et al.: Research on relaxation modulus of viscoelastic materials under unsteady temperature states based on TTSP. Mech. Time-Depend. Mater. 17(4), 543–556 (2013)

Xu, J., Chen, X., Wang, H., et al.: Thermo-damage-viscoelastic constitutive model of HTPB composite propellant. Int. J. Solids Struct. 51(18), 3209–3217 (2014)

Yu, C., Liu, T.-f., Tan, H.-m.: Study on the micromechanics of the NEPE solid propellant. Chin. J. Explos. Propellants 31(1), 56–59 (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Q., Fang, Qz., Sha, Bl. et al. Study on a damage model of NEPE solid propellant based on a Weibull distribution. Mech Time-Depend Mater 27, 19–34 (2023). https://doi.org/10.1007/s11043-021-09526-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-021-09526-9