Abstract

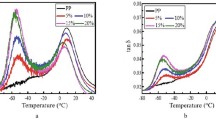

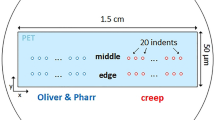

This paper considers the experimental characterization of isothermal physical aging of PEEK and PPS films using a dynamic mechanical analyzer. Using the short-term test method established by Struik, momentary creep and stress relaxation curves were measured at several temperatures within 15–35°C below the glass transition temperature (T g ) at various aging times. Stress and strain levels were such that the materials remained in the linear viscoelastic regime. These curves were then shifted together to determine momentary master curves and shift rates using the PHYAGE program. In order to validate the obtained isothermal physical aging behavior, the results of creep and stress relaxation testing were compared and shown to be consistent with one another using appropriate interconversion of the viscoelastic material functions. Time–temperature superposition of the master curves was also performed. The temperature shift factors and aging shift rates for both PEEK and PPS were consistent for both creep and stress relaxation test results.

Similar content being viewed by others

References

Bank, L.C., Gentry, T.R., et al.: Accelerated test methods to determine the long-term behavior of FRP composite structures: Environmental effects. J. Reinf. Plast. Compos. 14, 559–587 (1995)

Barbero, E.J., Julius, M.J.: Time–temperature-age viscoelastic behavior of commercial polymer blends and felt-filled polymers. Mech. Adv. Mater. Struct. 11, 287–300 (2004)

Bradshaw, R.D.: Charaterization and Modeling of Viscoelastic Composite Laminates with Nonisothermal Physical Aging. Northwestern University, Evanston (1997), p. 238

Bradshaw, R.D., Brinson, L.C.: Physical aging in polymers and polymer composites: An analysis and method for time–aging time superposition. Polym. Eng. Sci. 37(1), 31–44 (1997a)

Bradshaw, R.D., Brinson, L.C.: A sign control method for fitting and interconverting material functions for linearly viscoelastic solids. Mech. Time-Depend. Mater. 1, 85–108 (1997b)

Bradshaw, R.D., Brinson, L.C.: Mechanical response of linear viscoelastic composite laminates incorporating non-isothermal physical aging effects. Compos. Sci. Technol. 59(9), 1411–1427 (1999)

Brinson, L.C., Gates, T.S.: Effects of physical aging on long-term creep of polymers and polymer matrix composites. Int. J. Solids Struct. 32(6–7), 827–846 (1995)

Canadas, J.C., Diego, J.A., et al.: Comparative TSPC, TSDC and DSC physical ageing studies on PET-a. Polymer 39, 2795–2801 (1998)

Carfagna, C., Amendola, E., et al.: Physical aging of amorphous poly(etheretherketone) (peek). Polym. Eng. Sci. 28(18), 1203–1206 (1988)

Cheng, S.Z.D., Heberer, D.P., et al.: Structure and thermal history dependent enthalpy relaxation at the glass transition of semi-crystalline polyimides. Polymer 32, 2053–2059 (1991)

Cizmecioglu, M., Fedors, R.F., et al.: Effect of physical aging on stress relaxation of poly(methyl methacrylate). Polym. Eng. Sci. 21(14), 940–942 (1981)

D’Amore, A., Cocchini, F., et al.: The effect of physical aging on long-term properties of poly-ether-ketone (peek) and peek-based composites. J. Appl. Polym. Sci. 39(5), 1163–1174 (1990)

D’Amore, A., Pompo, A., et al.: Viscoelastic effects in poly(ether ether ketone) (peek) and peek-based composites. Compos. Sci. Technol. 41(3), 303–325 (1991)

Dong, Y., Ruan, Y., et al.: Studies on glass transition temperature of chitosan with four techniques. J. Appl. Polym. Sci. 93, 1553–1558 (2004)

Drozdov, A.D., Dorfmann, A.: Physical aging and the viscoelastic response of glassy polymers: Comparison of observations in mechanical and dilatometric tests. Math. Comput. Model. 37(7–8), 665–681 (2003)

Duran, R.S., McKenna, G.B.: A torsional dilatometer for volume change measurements on deformed glasses: Instrument description and measurements on equilibrated glasses. J. Rheol. 34, 813–839 (1990)

Ferry, J.D.: Viscoelastic Properties of Polymers. Wiley, New York (1980)

Fulchiron, R., Cassagnau, V.V., et al.: Deconvolution of polymer melt stress relaxation by the Pade–Laplace method. J. Rheol. 37(1), 17–34 (1993)

Gates, T.S., Feldman, M.: Time-dependent behavior of a graphite thermoplastic composite and the effects of stress and physical aging. J. Compos. Technol. Res. 17(1), 33–42 (1995)

Gates, T.S., Veazie, D.R., et al.: A comparison of tension and compression creep in a polymeric composite and the effects of physical aging on creep (NASA-TM-110273), NASA, 1996

Hernandez, M.C., Suarez, N.: Physical aging effects on high temperature relaxation of poly(DTH carbonate) and poly(DTO carbonate) monitored by TSPC and TSDC. Polymer 45, 8491–8499 (2004)

Hopkins, I.L., Hamming, R.W.: On creep and relaxation. J. Appl. Phys. 28(8), 906–912 (1957)

Hourston, D.J., Song, M., et al.: Modulated differential scanning calorimetry: 2. Studies of physical ageing in polystyrene. Polymer 37, 243–247 (1996)

Hu, W., Liu, B., et al.: Physical aging behavior of 6F-PEEK and m-PEEK studied by moduluated differential scanning calorimetry. J. Appl. Polym. Sci. 96, 312–317 (2005)

Kemmish, D.J., Hay, J.N.: The effect of physical aging on the properties of amorphous peek. Polymer 26(6), 905–912 (1985)

Kovacs, A.J.: Transition Vitreuse dans les Polymeres. Etude Phenomelogique (Vitreous transition in amorphous polymers. Phenomenological study). Fortschritte der Hochpolymeren-Forschung 3, 394–507 (1963)

Krishnaswamy, R.K., Geibel, J.F., et al.: Influence of semicrystalline morphology on the physical aging characteristics of poly(phenylene sulfide). Macromolecules 36(8), 2907–2914 (2003)

Lee, A., McKenna, G.B.: Viscoelastic response of epoxy glasses subjected to different thermal treatments. Polym. Eng. Sci. 30(7), 431–435 (1990)

Lee, A., McKenna, G.B.: Anomalous aging in two-phase systems: Creep and stress relaxation in rubber-toughened epoxies. J. Polym. Sci. Part B–Polym. Phys. 35, 1167–1174 (1997)

Ma, C.C.M., Lee, C.L., et al.: Effect of physical aging on the toughness of carbon fiber-reinforced poly(ether ether ketone) and poly(phenylene sulfide) composites.1. Polym. Compos. 13(6), 441–447 (1992)

Matsumoto, D.S.: Time–temperature superposition and physical aging in amorphous polymers. Polym. Eng. Sci. 28(20), 1313–1317 (1988)

McKenna, G.B.: Dilatometric evidence for the decoupling of glassy structure from the mechanical stress field. J. Non-Crystal. Solids 172–174, 756–764 (1994)

McKenna, G.B.: Comments on ‘Isobaric volume and enthalpy recovery of glasses. II. A Transparent Multiparameter Theory, by A.J. Kovacs, J.J. Aklonis, J.M. Hutchinson, and A.R. Ramos, J. Polym. Sci. Phys. Ed., 17, 1097 (1979)’. J. Polym. Sci. Part B–Polym. Phys. 34, 2463–2465 (1996)

Miyano, Y., Nakada, M., et al.: Effect of physical aging on the creep deformation of an epoxy resin. Mech. Time-Depend. Mater. 4(1), 9–20 (2000)

Muzeau, E., Vigier, G., et al.: Changes of thermodynamic and dynamic mechanical properties of poly(methyl methacrylate) due to structural relaxation: Low-temperature ageing and modelling. Polymer 36, 611–620 (1995)

O’Connell, P.A., McKenna, G.B.: Large deformation response of polycarbonate: Time–temperature, time–aging time, and time–strain superposition. Polym. Eng. Sci. 37(9), 1485–1495 (1997)

Ogale, A.A., McCullough, R.L.: Physical aging characteristics of polyether ether ketone. Compos. Sci. Technol. 30(2), 137–148 (1987)

Read, B.E., Dean, G.D., et al.: Physical aging and creep in PVC. Polymer 33(13), 2689–2698 (1992)

Robertson, C.G., Wilkes, G.L.: Refractive index: A probe for monitoring volume relaxation during physical aging of glassy polymers. Polymer 39(11), 2129–2133 (1998)

Robertson, C.G., Wilkes, G.L.: Physical aging behavior of miscible blends containing atactic polystyrene and poly(2,6-dimethyl-1, 4-phenylene oxide). Polymer 41, 9191–9204 (2000)

Santore, M.M., Duran, R.S., et al.: Volume recovery in epoxy glasses subjected to torsional deformations – the question of rejuvenation. Polymer 32(13), 2377–2381 (1991)

Schwarzl, F.R., Kaschta, J.: Physical aging and shear creep of poly(carbonate). Mech. Time-Depend. Mater. 2, 13–36 (1998)

Spinu, I., McKenna, G.B.: Physical aging of nylon-66. Polym. Eng. Sci. 34(24), 1808–1814 (1994)

Spinu, I., McKenna, G.B.: Physical aging of thin films of nylon and PET. J. Plast. Film Sheeting 13, 311–326 (1997)

Struik, L.C.E.: Physical Aging in Amorphous Polymers and Other Materials. Elsevier, Amsterdam (1978)

Struik, L.C.E.: On the rejuvenation of physically aged polymers by mechanical deformation. Polymer 38(16), 4053–4057 (1997)

Sullivan, J.L., Blais, E.J., et al.: Physical aging in the creep-behavior of thermosetting and thermoplastic composites. Compos. Sci. Technol. 47(4), 389–403 (1993)

TA Instruments: RSA3 Rheometrics System Analyzer. TA Instruments, New Castle (2003)

Tomlins, P.E.: Comparison of different functions for modeling the creep and physical ageing effects in plastics. Polymer 37(17), 3907–3913 (1996)

Tomlins, P.E., Read, B.E.: Creep and physical ageing of polypropylene: A comparison of models. Polymer 39(2), 355–367 (1998)

Tomlins, P.E., Read, B.E., et al.: The effect of temperature on creep and physical aging of poly(vinyl chloride). Polymer 35(20), 4376–4381 (1994)

Tool, A.Q.: Relations between inelastic deformability and thermal expansion of glass in its annealing range. J. Am. Ceram. Soc. 29, 240–253 (1946)

Tschoegl, N.W.: The Phenomenological Theory of Linear Viscoelasticity: An Introduction. Springer, Berlin (1989)

Vleeshouwers, S., Jamieson, A.M., et al.: Effect of physical aging on tensile-stress relaxation and tensile creep of cured Epon-828 epoxy adhesives in the linear viscoelastic region. Polym. Eng. Sci. 29(10), 662–670 (1989)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Y., Bradshaw, R.D. Isothermal physical aging characterization of Polyether-ether-ketone (PEEK) and Polyphenylene sulfide (PPS) films by creep and stress relaxation. Mech Time-Depend Mater 11, 61–89 (2007). https://doi.org/10.1007/s11043-007-9032-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-007-9032-7