Abstract

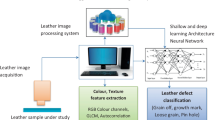

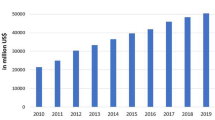

Increasing consumer quality awareness and increase in consumer wealth drives the market demand for high quality leather and leather products. Reliable and effective detection and classification of leather surface defects is of profound significance to tanneries and industries where leather is a major raw material for leather accessories and leather parts manufacturers. This paper presents a methodical and a detailed review of the leather surface defects detection methods starting from leather image acquisition, leather image processing, feature extraction and classification for defect detection. Firstly, we introduce the fundamentals of leather image acquisition and various related image processing methods, feature extraction and classification for the defect inspection. Next, the existing datasets and summary of the recent methodologies used in this field are discussed. Finally, the challenges and suggested improvements to further the development of the application of advanced Machine Learning and Deep Learning in this field are discussed. Deep learning algorithms are shown to have a great potential for leather surface defect detection and can help prepare a robust system that would greatly guarantee quality leather and provide monetary wealth from such leather products. Finally, research guidelines are presented to fellow researchers regarding data augmentation, leather defect detection models which need to be investigated in the future to make progress in this crucial area of research.

Similar content being viewed by others

References

Ahuja N, Rosenfeld A (1981) Mosaic models for textures. IEEE Trans Pattern Anal Mach Intell 3(1):1–11

Amorim WP, Pistori H, Jacinto MAC (2009) A comparative analysis of attribute reduction algorithms applied to wet-blue leather defects classification. In Embrapa Pecuária Sudeste-Artigo em anais de congresso (ALICE). In: BRASILIAN SYMPOSIUM ON COMPUTER GRAPHICS AND IMAGE PROCESSING, 22., 2009, Rio de Janeiro. Proceedings... Rio de Janeiro: PUC, 2009

Amorim WP, Pistori H, Pereira MC, Jacinto MAC (2010) Attributes reduction applied to leather defects classification. In 2010 23rd SIBGRAPI conference on Graphics, patterns and images (pp. 353-359). IEEE

Aslam M, Khan TM, Naqvi SS, Holmes G, Naffa R (2019) On the application of automated machine vision for leather defect inspection and grading: a survey. IEEE Access 7:176065–176086

Bong HQ, Truong QB, Nguyen HC, Nguyen MT (2018) Vision-based inspection system for leather surface defect detection and classification. In 2018 5th NAFOSTED conference on information and computer science (NICS) (pp. 300-304). IEEE

Bowman CC, Hilton PJ, Power PW, Hayes MP, Gabric RP (1996) Sheep-pelt grading using laser scanning and pattern recognition. In machine vision applications, architectures, and systems integration V (Vol. 2908, pp. 33-42). International Society for Optics and Photonics

Branca A (1997) Leather inspection through singularities detection using wavelet transforms. International Conference on Image Analysis and Processing. Springer, Berlin, Heidelberg

Branca A, Attolico G, Distante A (1996) Multiscale data analysis for leather defect detection. In machine vision applications, architectures, and systems integration V (Vol. 2908, pp. 97-108). International Society for Optics and Photonics

Branca A, Lovergine FP, Attolico G, Distante A (1997) Defect detection on leather by oriented singularities. In international conference on computer analysis of images and patterns (pp. 223-230). Springer, Berlin, Heidelberg

Casey P, Altobelli G, Pignatelli P (2009) Application of the hypothesis analysis method using Cohen’s kappa index to measure the agreement between leather sorters. Journal of the Society of Leather Technology and Chemists (JSLTC) 94:144–149

Chetverikov D, Lerch A (1990) A matching algorithm for motion analysis of dense populations. Pattern Recogn Lett 11(11):743–749

Darwish AM, Jain AK (1988) A rule based approach for visual pattern inspection. IEEE Trans Pattern Anal Mach Intell 10(1):56–68

Fair project improving hide and skin quality, (1998) (https://leathercouncil.org/fair/index.htm). Accesssed 20 Aug 2018

Fuqiang H, Wang W, Zichen C (2006) "Automatic defects detection based on adaptive wavelet packets for leather manufacture." : 2024-2027

Gonzalez RC, Thomason MG (1978) Syntactic pattern recognition: an introduction

Haralick RM (1979) Statistical and structural approaches to texture. Proc IEEE 67(5):786–804

He FQ, Wang W, Chen ZC (2006) Automatic visual inspection for leather manufacture. In key engineering materials (Vol. 326, pp. 469-472). Trans tech publications ltd

Ho CC, Li JC, Kuo TH, Peng CC (2013) Multicamera fusion-based leather defects marking system. Advances in Mechanical Engineering 5:347921

Hoang K, Wen W, Nachimuthu A, Jiang XL (1997) Achieving automation in leather surface inspection. Comput Ind 34(1):43–54

Jawahar M, Babu NC, Ismail MM, Vani K (2016) Compression of leather images for automatic leather grading system using multiwavelet. In 2016 IEEE international conference on computational intelligence and computing research (ICCIC) (pp. 1-7). IEEE

Jawahar M, Babu NC, Vani KLJA, Anbarasi LJ, Geetha S (2021) Vision based inspection system for leather surface defect detection using fast convergence particle swarm optimization ensemble classifier approach. Multimed Tools Appl 80(3):4203–4235

Jian L, Wei H, Bin H (2010) Research on inspection and classification of leather surface defects based on neural network and decision tree. In 2010 international conference on computer design and applications (Vol. 2, pp. V2-381). IEEE

Kasi MK, Rao JB, Sahu VK (2014) Identification of leather defects using an autoadaptive edge detection image processing algorithm. In 2014 international conference on high performance computing and applications (ICHPCA) (pp. 1-4). IEEE

Krastev K, Georgieva L (2005) Identification of leather surface defects using fuzzy logic. In Proceedings of the International Conference on Computer Systems and Technologies

Krastev K, Georgieva L (2006) A method for leather quality determination using fuzzy neural networks. In Proceedings of the International Conference on Computer Systems and Technologies

Krastev K, Georgieva L, Angelov N (2004) Leather features selection for defects recognition using fuzzy logic. Energy 2(3):1–6

Kumar A (2008) Computer-vision-based fabric defect detection: a survey. IEEE Trans Ind Electron 55(1):348–363

Kumar A, Pang G (2001) Identification of surface defects in textured materials using wavelet packets. In conference record of the 2001 IEEE industry applications conference. 36th IAS annual meeting (cat. No. 01CH37248) (Vol. 1, pp. 247-251). IEEE

Kwak C, Ventura JA, Tofang-Sazi K (2000) A neural network approach for defect identification and classification on leather fabric. J Intell Manuf 11(5):485–499

Kwak C, Ventura JA, Tofang-Sazi K (2001) Automated defect inspection and classification of leather fabric. Intelligent Data Analysis 5(4):355–370

Kwon JW, Choo YY, Choi HH, Cho JM, KiI GS (2004) Development of leather quality discrimination system by texture analysis. In 2004 IEEE region 10 conference TENCON 2004. (pp. 327-330). IEEE

Leng L, Zhang J (2011) Dual-key-binding cancelable palmprint cryptosystem for palmprint protection and information security. J Netw Comput Appl 34(6):1979–1989

Leng L, Teoh ABJ, Li M, Khan MK (2014) A remote cancelable palmprint authentication protocol based on multi-directional two-dimensional PalmPhasor-fusion. Security and Communication Networks 7(11):1860–1871

Leng L, Li M, Kim C, Bi X (2017) Dual-source discrimination power analysis for multi-instance contactless palmprint recognition. Multimed Tools Appl 76(1):333–354

Lerch A, Chetverikov D (1991) Knowledge-based line-correction rules in a machine-vision system for the leather industry. Eng Appl Artif Intell 4(6):433–438

Limas-Serafim AF (1993) Natural images segmentation for patterns recognition using edges pyramids and its application to the leather defects. In Proceedings of IECON'93-19th Annual Conference of IEEE Industrial Electronics (pp. 1357–1360). IEEE

Liong ST, Zheng D, Huang YC, Gan YS (2020) Leather defect classification and segmentation using deep learning architecture. Int J Comput Integr Manuf 33(10–11):1105–1117

Lovergine FP, Branca A, Attolico G, Distante A (1997) Leather inspection by oriented texture analysis with a morphological approach. In proceedings of international conference on image processing (Vol. 2, pp. 669-671). IEEE

Lu L, Beng A, Teoh J (2015) Alignment-free row-co-occurrence cancelable palmprint. Fuzzy Vault Pattern Recogn 48(7):2290–2303

Neto MM, Vendrametto O, Fusco JPA (2004) Automated system for leather inspection: the machine vision. In international conference on information Technology for Balanced Automation Systems (pp. 387-396). Springer, Boston, MA

Peters S, Koenig A (2007) A hybrid texture analysis system based on non-linear & oriented kernels, particle swarm optimization, and kNN vs. support vector machines. In 7th international conference on hybrid intelligent systems (HIS 2007) (pp. 326-331). IEEE

Pistori H, Paraguassu WA, Martins PS, Conti MP, Pereira MA, Jacinto MA (2018) Defect detection in raw hide and wet blue leather. In proc. Int. Symp. CompIMAGE (p. 355)

Poelzleitner W, Niel A (1994) Automatic inspection of leather surfaces. In machine vision applications, architectures, and systems integration III (Vol. 2347, pp. 50-58). International Society for Optics and Photonics

Rao AR (2012) A taxonomy for texture description and identification. Springer Science & Business Media

Serafim AL (1991) Multiresolution pyramids for segmentation of natural images based on autoregressive models: application to calf leather classification. In proceedings IECON'91: 1991 international conference on industrial electronics, control and instrumentation (pp. 1842-1847). IEEE

Serafim AL (1992) Segmentation of natural images based on multiresolution pyramids linking of the parameters of an autoregressive rotation invariant model. Application to leather defects detection. In 11th IAPR international conference on pattern recognition. Vol. III. Conference C: image, speech and signal analysis, (Vol. 1, pp. 41-44). IEEE computer society

Serafim AL (1992) Object detection in images of natural scenes represented by AR models using Laplacian pyramids: application to leather defects localization. In proceedings of the 1992 international conference on industrial electronics, control, instrumentation, and automation (pp. 716-720). IEEE

Sobral JL (2005) Leather inspection based on wavelets. In Iberian conference on pattern recognition and image analysis (pp. 682-688). Springer, Berlin, Heidelberg

Tafuri M, Branca A, Attolico G, Distante A, Delaney W (1996) Automatic leather inspection of defective patterns. In machine vision applications in industrial inspection IV (Vol. 2665, pp. 108-119). International Society for Optics and Photonics

Tuceryan M, Jain AK (1993) Texture analysis. Handbook of pattern recognition and computer vision, 235–276

Viana R, Rodrigues RB, Alvarez MA, Pistori H (2007) SVM with stochastic parameter selection for bovine leather defect classification. In Pacific-rim Symposium on image and video technology (pp. 600-612). Springer, Berlin, Heidelberg

Villar P, Mora M, Gonzalez P (2011) A new approach for wet blue leather defect segmentation. In Iberoamerican congress on pattern recognition (pp. 591-598). Springer, Berlin, Heidelberg

Wang L, Liu C (2007) Tanning leather classification using an improved statistical geometrical feature method. In 2007 international conference on machine learning and cybernetics (Vol. 3, pp. 1765-1768). IEEE

Wang Q, Liu H, Liu J, Wu T (1992) A new method for leather texture image classification. In [1992] proceedings of the IEEE international Symposium on industrial electronics (pp. 304-307). IEEE

Winiarti S, Prahara A, Murinto DPI, Ismi P (2018) Pretrained convolutional neural network for classification of tanning leather image. Network (CNN) 9(1):9

Yeh C, Perng DB (2001) Establishing a demerit count reference standard for the classification and grading of leather hides. Int J Adv Manuf Technol 18(10):731–738

Yeh C, Perng DB (2005) A reference standard of defect compensation for leather transactions. Int J Adv Manuf Technol 25(11–12):1197–1204

Zhang YF, Bresee RR (1995) Fabric defect detection and classification using image analysis. Text Res J 65(1):1–9

Acknowledgements

The authors gratefully acknowledge the Ministry of Electronics and Information Technology (MeitY), Goverenment of India for funding this research and Director, CSIR-CLRI for his support during the project. (A/2020/LPT/GAP1811/1374).

Funding

This is a work carried out as a part of the Funded Project in Central Leather Research Institute.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no Conflict of interests /competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jawahar, M., Anbarasi, L.J. & Geetha, S. Vision based leather defect detection: a survey. Multimed Tools Appl 82, 989–1015 (2023). https://doi.org/10.1007/s11042-022-13308-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-022-13308-x