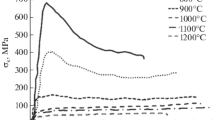

The structure, the phase composition, and the physical and mechanical properties of a hot-forged billet from titanium alloy VT14 are studied by the methods of microstructural and x-ray diffraction analyses, micro-indentation, thermodynamic computations with the help of the ThermoCalc software, and thermomechanical tests in a Gleeble 3800 facility. The flow stress and the strain heating are shown to depend on the degree of deformation in compressive and tensile tests at strain rates 1 and 10 sec – 1 and temperatures 900, 925, 950, and 975°C. The results of the study are analyzed and compared to the available reported data.

Similar content being viewed by others

References

A. A. Il’in, B. A. Kolachev, and I. S. Pol’kin, Titanium Alloys, Composition, Structure, Properties [in Russian], VILS-MATI, Moscow (2009), 520 p.

V. N. Moiseyev, Titanium Alloys: Russian Aircraft and Aerospace Applications, CRC Press, Boca Raton, FL, USA (2006).

V. N. Moiseyev, F. R. Kulikov, Yu. T. Kirillov, and L. V. Sholokhova, Welded Joints of Titanium Alloys [in Russian], Metallurgiya, Moscow (1979), 248 p.

Anil Kumar, R. K. Gupta, S. K. Manwatkar, et al., “Effect of prior and post-weld heat treatment on electron beam weldments of (α + β) titanium alloy Ti – 5Al – 3Mo – 1.5V,” J. Mater. Eng. Perform., 25(6), 2147 – 2156 (2016). https://doi.org/10.1007/s11665-016-2111-7

M. G. Golkovski, V. V. Samoylenko, I. A. Polyakov, et al., “Welding of a corrosion-resistant composite material based on VT14 titanium alloy obtained using an electron beam emitted into the atmosphere,” IOP Conf. Ser., Mater. Sci. Eng., 168, 012076 (2017). https://doi.org/10.1088/1757-899X/168/1/012076

V. A. Bataev, M. G. Golkovski, V. V. Samoylenko, et al., “Structure and mechanical properties of a two-layered material produced by the E-beam surfacing of Ta and Nb on the titanium base after multiple rolling,” Appl. Surf. Sci., 437, 181 – 189 (2018). https://doi.org/10.1016/j.apsusc.2017.12.114

V. K. Aleksandrov, N. F. Anoshkin, A. P. Belozerov, et al., Semiproducts from Titanium Alloys [in Russian], VILS, Moscow (1966), 560 p.

P. I. Polukhin, G. Ya. Gun, and A. M. Galkin, Plastic Deformation Resistance of Metals and Alloys [in Russian], Metallurgiya, Moscow (1983), 352 p.

L. A. Nikol’skii, S. Z. Figlin, V. V. Boytsov, et al., Hot Forging and Pressing of Titanium Alloys [in Russian], Mashinostroenie, Moscow (1975), 285 p.

A. O. Mosleh, A. V. Mikhaylovskaya, A. D. Kotov, et al., “Experimental investigation of the effect of temperature and strain rate on the superplastic deformation behavior of Ti-based alloys in the (α + β) temperature field,” Metals, 8, 819 (2018). https://doi.org/10.3390/met8100819

A. O. Mosleh, A. D. Kotov, P. Metsre-Rinn, and A. V. Mikhaylovskaya, “Superplastic forming of Ti – 4Al – 2Mo – 1V alloy: Flow behavior modelling and finite element simulation,” Proc. Manuf., 37, 239 – 246 (2019).

Ya. I. Kosmatskii, B. V. Barichko, N. V. Fokin, and V. D. Nikolenko, “Use of Gleeble 3800 complex in development of technology of hot pressing and upsetting of pipe ends,” Metallurg, No. 4, 36 – 41 (2021).

A. G. Illarionov, F. V. Vodolazskii, Ya. I. Kosmatskii, and E. A. Gornostaeva, “Determining temperatures and forces necessary to produce hot-pressed tubes from titanium alloy PT-1M,” Tsvetn. Met., No. 2, 77 – 83 (2021). https://doi.org/10.17580/tsm.2021.02.09

S. A. Saltykov, Stereometric Metallography [in Russian], Metallurgiya, Moscow (1976), 270 p.

S. G. Glazunov and B. A. Kolachev (eds.), Titanium Alloys. The Metallography of Titanium Alloys [in Russian], Metallurgiya, Moscow (1980), 464 p.

H. M. Rietveld, “The Rietveld method,” Phys. Scr., 89(9), Art. 098002 (2014). https://doi.org/10.1088/0031-8949/89/9/098002

W. C. Oliver and G. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res., 7(6), 1564 – 1583 (1992).

A. G. Illarionov, F. V. Vodolazskiy, N. A. Barannikova, et al., “Influence of phase composition on thermal expansion of Ti – 0.4Al, Ti – 2.2Al and Ti – 3Al – 2.5V alloys,” J. Alloys Compd., 857, Art. 158049. https://doi.org/10.1016/j.jallcom.2020.158049

A. G. Illarionov, A. S. Ushakova, and F. V. Vodolazsky, “ThermoCalc modelling of the effect of chemical composition on the phase transformations temperatures of Ti – 0.4Al alloy,” IOP Conf. Ser., Mater. Sci. Eng., 969, Art. 012029 (2020). https://doi.org/10.1088/1757-899X/969/1/012029

F. V. Vodolazskiy, S. M. Illarionov, and E. A. Gornostaeva, “Calculation of phase composition of α- and near-α-titanium alloys,” Solid State Phenom., 299, 403 – 408 (2020). https://doi.org/10.4028/www.scientific.net/SSP.299.403

S. G. Glazunov and B. N. Moiseev, Structural Titanium Alloys [in Russian], Metallurgiya, Moscow (1974), 368 p.

M. L. Bernshteinand A. G. Rakhshtadt (eds.), Physical Metallurgy and Heat Treatment of Steel, in 3 vols, Vol. 1. Methods of Testing and Research, in 2 books, Book 2 [in Russian], Metallurgiya, Moscow (1991), 462 p.

F. W. Syed, V. Anil Kumar, R. K. Gupta, and A. K. Kanjarla, “Role of microstructure on the tension/compression asymmetry in two-phase Ti – 5Al – 3Mo – 1.5V titanium alloy,” J. Alloys Compd., 975, 151 – 162 (2019). https://doi.org/10.1016/j.jallcom.2019.04.272

M. Kh. Shorshorov, The Physical Metallurgy of Steel and Titanium Alloys [in Russian], Nauka, Moscow (1965), 336 p.

P. I. Polukhin, S. S. Gorelik, and V. K. Vorontsov, Physical Fundamentals of Plastic Deformation [in Russian], Metallurgiya, Moscow (1982), 584 p.

Ya. I. Kosmatskii, N. V. Fokin, E. A. Filyaeva, and B. V. Barichko, “A study of the deformability of tube billet from titanium alloy of grade PT-1M,” Vestn. Yuzh.-Ural. Gos. Univer., Ser. Metall., 17(4), 83 – 91 (2017).

Ya. I. Kosmatskii, N. V. Fokin, E. A. Filyaeva, and B. V. Barichko, “A study of the deformability of titanium alloy Ti – 3Al – 2.5V and assessment of the technological possibility of fabrication of hot-pressed tubes from it,” Titan, No. 2, 18 – 22 (2016).

Ya. I. Kosmatskii, N. V. Fokin, E. A. Filyaeva, and B. V. Barichko, “A study of the deformability of tube billet from titanium alloy of grade PT-7M,” Titan, No. 4(58), 34 – 39 (2017).

I. I. Korneev, V. M. Arzhakov, G. G. Barmashenko, et al. (eds.), Forging and Stamping of Nonferrous Metals [in Russian], Mashinostroenie, Moscow (1972), 232 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 33 – 39, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Illarionov, A.G., Vodolazskii, F.V., Kosmatskii, Y.I. et al. Effect of the Temperature and Rate Parameters of Hot Deformation on the Mechanical Behavior of Forged Titanium Alloy VT14 Under Compression and Tension. Met Sci Heat Treat 65, 426–431 (2023). https://doi.org/10.1007/s11041-023-00950-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00950-x