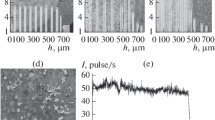

The effect of laser hardening and of gas nitriding on the microstructure and wear resistance of steel P20 (the Russian counterpart is 38KhNM) is studied. The phase composition and the microhardness of the hardened surface layers are determined and their microstructure is studied. Wear tests are performed. It is shown that both treatments raise the hardness of the steel. However, the nitrided layer has a higher resistance to plastic deformation, a higher indentation modulus, and a much higher wear resistance than the laser hardened layer. Laser hardening produces a deeper hardened layer, whereas gas nitriding provides a higher wear resistance of steel P20.

Similar content being viewed by others

References

S. Lampman, “Introduction to surface hardening of steels,” in: ASM Handbook. Vol. 4. Heat Treating, ASM International Park, OH (1997), pp. 259 – 267.

B. Liu, B. Wang, X. Yang, et al, “Thermal fatigue evaluation of AISI H13 steels surface modified by gas nitriding with pre- and post-shot peening,” Appl. Surf. Sci., 483, 45 – 51 (2019).

A. Y. Kondrat’ev, V. I. Gorynin, and V. O. Popov, “Optimization of the parameters of the surface-hardened layer in laser quenching of components,” Weld. Int., 26(8), 629 – 632 (2012).

A. I. Rudskoi, S. Yu. Kondrat’ev, Yu. A. Sokolov, and V. N. Kopaev, “Simulation of the layer-by-layer synthesis of articles with an electron beam,” Tech. Phys., 60(11), 1663 – 1669 (2015).

Yu. A. Sokolov, N. V. Pavlushin, and S. Yu. Kondrat’ev, “New additive technologies based on ion beams,” Russ. Eng. Res., 36(12), 1012 – 1016 (2016).

M. H. Ameri, F. M. Ghaini, and M. J. Torkamany, “Investigation into the efficiency of a fiber laser in surface hardening of ICD-5 tool steel,” Opt. Laser Technol., 107, 150 – 157 (2018).

C. Soriano, J. Leunda, J. Lambarri, et al., “Effect of laser surface hardening on the microstructure, hardness and residual stresses of austempered ductile iron grades,” Appl. Surf. Sci., 257(16), 7101 – 7106 (2011).

S. Roy, J. Zhao, P. Shrotriya, et al., “Effect of laser treatment parameters on surface modification and tribological behavior of AISI 8620 steel,” Tribol. Int., 112, 94 – 102 (2017).

G. Yan, S. Lu, M. Zhang, et al., “Wear and corrosion behavior of P20 steel surface modified by gas nitriding with laser surface engineering,” Appl. Surf. Sci., 530, 147306 (2020).

L. A. Giannuzzi and F. A. Stevie, “A review of focused ion beam milling techniques for TEM specimen preparation,” Micron, 30(3), 197 – 204 (1999).

E. A. Ochoa, C. A. Figueroa, and F. Alvarez, “The influence of the ion current density on plasma nitriding process,” Surf. Coat. Technol., 200(7), 2165 – 2169 (2005).

P. Dinesh Babu, K. R. Balasubramanian, and G. Buvanashekaran, “Laser surface hardening: a review,” Int. J. Surf. Sci. Eng., 5(2 – 3), 131 – 151 (2011).

H. Liu, J. Liu, P. Chen, et al., “Microstructure and high temperature wear behaviour of in-situ TiC reinforced AlCoCrFeNi-based high-entropy alloy composite coatings fabricated by laser cladding,” Opt. Laser Technol., 118, 140 – 150 (2019).

X. Liu, W. Lei, L. Ma et al., “On the microstructures, phase assemblages and properties of Al0.5CoCrCuFeNiSix high-entropy alloys,” J. Alloys Compd., 630, 151 – 157 (2015).

H. Liu, S. Sun, T. Zhang, et al., “Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding,” Surf. Coat. Technol., 405, 126522 (2021).

G. Krauss, “Tempering of martensite in carbon steels,” in: Phase Transformations in Steels, Woodhead Publishing (2012), pp. 126 – 150.

R. K. Shiue and C. Chen, “Laser transformation hardening of tempered 4340 steel,” Metall. Trans. A, 23(1), 163 – 170 (1992).

M. F. Yan, Y. Q. Wu, and R. L. Liu, “Plasticity and ab initio characterizations on Fe4N produced on the surface of nanocrystallized 18Ni-maraging steel plasma nitrided at lower temperature,” Appl. Surf. Sci., 255(21), 8902 – 8906 (2009).

ISO 14577-1:2015. Metallic Materials-Instrumented Indentation Test for Hardness Materials Parameters – Part 1: Test Method, ISO, Genève (2015).

W. S. Gwidon and W. B. Andrew, “Fatigue wear,” in: W. S. Gwidon and W. B. Andrew (eds.), Engineering Tribology, Elsevier, Oxford (2006), pp. 595 – 619.

T. J. Rupert and C. A. Schuh, “Sliding wear of nanocrystalline Ni – W: structural evolution and the apparent breakdown of Archard scaling,” Acta Mater., 58(12), 4137 – 4148 (2010).

J. A. Williams, “Wear and wear particles — some fundamentals,” Tribol. Int., 38(10), 863 – 870 (2005).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 59 – 66, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, G., Yang, X., Gu, J. et al. Effect of Laser Hardening and Gas Nitriding on Wear Resistance of Steel P20: A Comparative Study. Met Sci Heat Treat 65, 247–253 (2023). https://doi.org/10.1007/s11041-023-00921-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00921-2