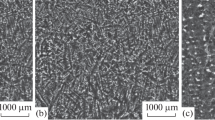

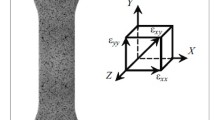

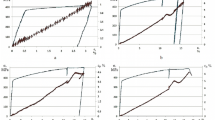

Special features of deformed condition of commercial thin slabs produced in a continuous cycle in a casting and rolling unit are studied. Quantitative metallography is used to measure the parameters of the dendrite structure at different degrees of reduction during the deformation of slabs in the roughing group. The changes occurring in the primary dendritic structure during the deformation are considered. It is shown that the relative change in the sizes of the dendrite structure over the thickness of the slab corresponds to the degree of the relative reduction under the rolling. The picture of strain distribution over the thickness of the pieces is presented.

Similar content being viewed by others

References

A. V. Muntin, “Advanced technologies for combined processes of continuous casting of thin slabs and hot rolling,” Metallurg, No. 9, 43 – 51 (2018).

A. V. Muntin, Yu. M. Kurenkov, and A. G. Kolbasnikov, “Advanced technological solutions and equipment for production of untrathin hot-rolled strip,” Listoprok. Proizvod., No. 8, 13 – 21 (2016).

A. V. Chervonny, Development of Compositions of Micro- alloyed Steels for Electrowelded Pipes of strength classes K56 – K60 and Modes for Their controlled rolling under the Conditions of Casting and Rolling Unit, Author’s Abstract of Candidate’s Thesis [in Russian], Moscow (2021), 16 p.

V. V. Kislitsa, E. N. Maksaev, A. S. Boiko, et al., “Estimation of qualitative parameters of slabs and rolled strips upon elevation of the thickness of the continuously cast billet,” Stal’, No. 8, 17 – 21 (2021).

V. V Kislitsa, E. N. Maksaev, A. S. Boiko, et al., “Raising the efficiency of a casting and rolling unit,” Metallurg, No. 4, 18 – 24 (2022).

A. V. Aldunin and A. V. Shumeev, “A study of the distribution of plastic strain over the thickness of steel strips,” Izv. MGTU “MAMI,” No. 4,4–8 (2014).

Tadanobu Inoue, Hai Qui, and Rintaro Ueji, “Through-thickness microstructure and strain distribution in steel sheets rolled in a large-diameter rolling process,” Metals, 10, 91 (2020); www.mdpi.com/journal/metals.

A. V. Aldunin, “Leveling of structure over the thickness of steel strips under rolling,” Izv. MGTU “MAMI,” No. 1,5–8 (2015).

G. V. Levchenko, E. G. Demina, S. A. Vorobey, and G. A. Medinskii, “Assessment of deformed state of a metal from changes in the parameters of dendritic structure,” Metall. Gornrrudn. Prom-st’, No. 5, 71 – 75 (2009).

G. V. Levchenko, E. E. Nefed’eva, A. I. Serov, et al., “Formation of structure and mechanical properties in round rolled products from continuously cast steel,” Metal Lit’e Ukrainy,” No. 6, 3 – 7 (2011).

G. V. Levchenko, S. A. Vorobey, E. G. Demina, and Zh. A. Dement’eva, “Development of a method for assessing through-thickness processing of the structure of structural steel during hot deformation and fracture of materials and nanomaterials,” in: VIII Int. Conf. ‘Deformation and Fracture of Materials and Nanomaterials,’ Moscow, 19 – 22 Nov. 2019 [in Russian], IMET RAN, Moscow (2019), pp. 42 – 43.

H. Presslinger, M. Mayr, E. Tragl, and Ch. Bernard, “Assessment of the primary structure of slabs and the influence of hot- and cold-rolled strip structure,” Steel Res. Int., 77(2), 107 – 115 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 34 – 40, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vorozheva, E.L., Kudashov, D.V., Khlybov, A.A. et al. Assessment of Deformation Behavior of Thin Slabs by the Method of Quantitative Metallography. Met Sci Heat Treat 65, 221–227 (2023). https://doi.org/10.1007/s11041-023-00917-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00917-y