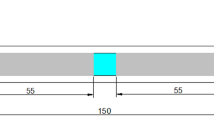

The effect of additions of alloying elements (Mo and Ni), austempering time and thickness of the product section on the mechanical properties of industrial ductile iron of grade GGG-70 (EN-GJS-700-2) is studied. Standard keel blocks and crankshafts have been produced by static sand casting from unalloyed, alloyed with 0.2% Mo and 0.2% Mo + 0.6% Ni ductile iron. Austempering is carried out at 350 °C for 90, 120, 150, and 180 min in a salt bath. It is shown that the alloying has a significant effect on the ability of cast iron to austempering and its mechanical properties after heat treatment. Alloyed cast iron has the best combination of ultrahigh yield and tensile strength with high ductility. After austempering, crankshafts alloyed with 0.2% Mo + 0.6% Ni have a typical ductile iron ADI structure even in the thickest sections (58-mm-thick main bearing center) with a uniform hardness distribution.

Similar content being viewed by others

References

J. Janowak and B. Gundlach, “Development of a ductile iron for commercial austempering,” Trans. Amer. F, 91, 377 – 388 (1983).

J. Yang and S. K. Putatunda, “Effect of microstructure on abrasive wear behavior of austempered ductile iron (ADI) processed by a novel two-step austempering process,” Mater. Sci. Eng. A, 406A, 217 – 228 (2005).

J. Yang and S. K. Putatunda, “Improvement in strength and toughness of austempered ductile cast iron by a novel two-step austempering process,” Mater. Des., 25, 219 – 230 (2004).

S. K. Putanda, “Development of austempered ductile cast iron (ADI) with simultaneous high yield strength and fracture toughness by a novel two-step austempering process,” Mater. Sci. Eng. A, 315A, 70 – 80 (2001).

D. Rajnovic, O. Eric, and L. Sidjanin, “The standard processing window of alloyed ADI materials,” Kovove Mater., 50(3), 199 – 208 (2012).

L. L. T. Boneti, M. F. Hupalo, S. Vurobi junio, and A. M. Rosario, “Influence of casting heterogeneities on microstructure and mechanical properties of austempered ductile iron (ADI),” Matéria (Rio de Janeiro), 22(03), E11858 (2017).

J. R. Keough and K. L. Hayrynen, “Automotive applications of austempered ductile iron (ADI): A critical review,” SAE Trans., 109, 344 – 354 (2000).

A. Trudel and M. Gagne, “Effect of composition and heat treatment parameters on the characteristics of austempered ductile irons,” Can. Metall. Quart., 36, 289 – 298 (1997).

R. C. Voigt and C. Loper, “Austempered ductile iron—process control and quality assurance,” J. Mater. Eng. Perform., 22, 2776 – 2794 (2013).

L. Meier, M. Hofmann, P. Saal, et al., “In-situ measurement of phase transformation kinetics in austempered ductile iron,” Mater. Charact., 85, 124 – 133 (2013).

D. Myszka and A. Wieczorek, “An assessment of the applicability of austempered ductile iron containing Mo and Ni for mining machines parts,” Arch. Metall. Mater., 58(3), 953 – 956 (2013).

X. Li, J. N. Wagner, A Stark, et al., “Carbon redistribution process in austempered ductile iron (ADI) during heat treatment—APT and Synchrotron diffraction study,” Metals, 9, 789 (2019).

J. Lefevre and K. L. Hayrynen, “Austempered materials for power-train applications,” J. Mater. Eng. Perform., 22, 1914 – 1922 (2013).

P. Sellamuthu, D. Samuel, D. Dinakaran, et al., “Austempered ductile iron (ADI): influence of austempering temperature on microstructure, mechanical and wear properties and energy consumption,” Metals, 8, 53 (2018).

P. P. Rao and S. K. Putatunda, “Influence of microstructure on fracture toughness of austempered ductile iron,” Metall. Mater. Trans. A, 28(7), 1457 – 1470 (1997).

E. Konca, K. Tur, and E. Koç, “Effects of alloying elements (Mo, Ni, and Cu) on the austemperability of GGG-60 ductile cast iron,” Metals, 7, 320 (2017).

S. Yazdani and R. Elliott, “Influence of molybdenum on austempering behaviour of ductile iron. Part I—Austempering kinetics and mechanical properties of ductile iron containing 0.13% Mo,” Mater. Sci. Tech. Ser., 15(5), 531 – 540 (1999).

Y. Tanaka and H. Kage, “Development and application of austempered spheroidal graphite cast iron,” Mater. Trans., JIM, 33(6), 543 – 557 (1992).

B. Kovacs, “Development of austempered ductile iron (ADI) for automotive crankshafts,” J. Heat Treat., 5(1), 55 – 60 (1987).

M. H. Sohi, M. N. Ahmadabadi, and A. B. Vahdat, “The role of austempering parameters on the structure and mechanical properties of heavy section ADI,” J. Mater. Process. Technol., 153 – 154, 203 – 208 (2004).

R. Voigt, “Austempered ductile iron — processing and properties,” Cast Metals, 2(2), 71 – 93 (1989).

A. S. Benam, “Effect of alloying elements on austempered ductile iron (ADI) properties and its process,” China Foundry, 12, 54 – 70 (2015).

U. Batra, S. Ray, and S. R. Prabhakar, “The influence of nickel and copper on the austempering of ductile iron,” J. Mater. Eng. Perform., 13, 64 – 68 (2004).

U. Batra, S. Ray, and S. Prabhakar, “Impact properties of copper-alloyed and nickel-copper alloyed ADI,” J. Mater. Eng. Perform., 16, 485 – 489 (2007).

S. McFadden, R. Mishra, R. Valiev, et al., “Low-temperature superplasticity in nanostructured nickel and metal alloys,” Nature, 398, 684 – 686 (1999).

A. Basso, R. Martinez, and J. Sikora, “Influence of section size on dual phase ADI microstructure and properties: comparison with fully ferritic and fully ausferritic matrices,” Mater. Sci. Tech. Ser., 25, 271 – 1278 (2009).

J. Liu and R. Elliott, “The influence of cast structure on the austempering of ductile iron,” Int. J. Cast Met. Res., 11, 407 – 412 (1999).

O. Erić,M. Jovanović, L. Šid, et al., “The austempering study of alloyed ductile iron,” Mater. Des., 27(7), 617 – 622 (2006).

C. S. Roberts, “Effect of carbon on the volume fractions and lattice parameters of retained austenite and martensite,” JOM, 5(2), 203 – 204 (1953).

B. D. Cullity, Elements of X-Ray Diffraction, Addison-Wesley Publ., Massachusetts (1956), 534)p.

S. Ö. Erturk and O. Ahmet, “Investigation on the production of solution strengthened ductile iron part grade 500-14,” Bayburt Üniversitesi Fen Bilimleri Dergisi, 3, 106 – 109 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 3 – 12, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Keleş, A., Cengız, R. & Yildirim, M. Effect of Alloying Elements and Technological Parameters of Austempering on the Structure and Mechanical Properties of Ductile Cast Iron (ADI). Met Sci Heat Treat 65, 191–199 (2023). https://doi.org/10.1007/s11041-023-00914-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00914-1