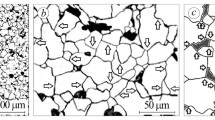

A fragment of a pipe from a chromium-manganese steel of type 12Kh15G9ND (AISI 201) is studied after 1.5 years of operation in an apartment building. The chemical composition of the steel is determined. The Vickers hardness of straight and curvilinear parts of the pipe is measured. The temperatures Ms and Md of martensitic transformations are computed. The macrostructure and the microstructure of the steel are studied. Places of through corrosion damage and causes of their formation in hot water supply (HWS) pipes are analyzed. A method of scratch testing is suggested for assessing the surface condition. The adhesive properties of the coating are estimated. It is inferred that steel 12Kh15G9ND is suitable for service in HWS systems and that total replacement of the chromium-nickel steel in pipelines by a chromium-manganese corrosion-resistant one requires further study.

Similar content being viewed by others

References

V. G. Pleshivtsev, Yu. A. Pak, and G. A. Filippov, “Factors lowering the structural strength of pipe metal for heating networks,” in: Rep. III Workshop “Heating Networks. Advanced Practical Solutions,” 11 – 13 March, 2008 [in Russian], Dep. TEKh Moscow, “YuNNAPAK” Company, Bardin TsNIIChermet, Moscow (2008), 5 p.

O. Grigor’ev, V. Petukhov, and V. Sokolov, “Malfunctions in the system of electric supply of buildings accelerate corrosion of pipelines,” Nov. Elektrotekh., No. 4(22) (2003).

Letter of the Association of Developers and Producers of Anticorrosion Protection for the Fuel and Power Complex (KARTEK) No. 1_2007 of 04.12.2000 [in Russian].

U. Krupp, C. West, H. J. Christ, “Deformation-induced martensite formation during cyclic deformation of metastable austenitic steel: Influence of temperature and carbon content,” Mater. Sci. Eng. A, 481, 713 – 717 (2008).

RD 34.17.430–94. Methodological Instructions on Determination of the Kind of corrosion Damage of the Metal of Heating Network Pipelines [in Russian].

N. A. Tereshchenko, A. I. Uvarov, and I. L. Yakovleva, “Effect of deformation twins on hardening of chromium-manganese austenitic steels,” Deform. Raszrush. Mater., No. 3, 1 – 6 (2010).

A. Pardo, M. S. Merino, A. E. Coy, et al., “Pitting corrosion behavior of austenitic stainless steels — combining effects of Mn and Mo additions,” Corr. Sci., 50(6), 1796 – 1806 (2008).

A. J. Sedriks, “Role of sulfide inclusions in pitting and crevice corrosion of stainless steels,” Int. Met. Rev., 28(5), 295 – 307 (1983).

H. Kaneko, T. Nishizawa, and K. Tamaki, J. Jpn. Inst. Met., 27, 299 (1963).

R. Bandy and D. van Rooyen, “Pitting-resistant alloys in highly concentrated chloride media,” Corrosion, 39(6), 227 – 236 (1983).

Shi Feng, Cui Wenfang, Wang Lijun, et al., “Research progress in the field of austenitic stainless steel with high nitrogen content,” Shanghai Metals, 28(5), 45 – 50 (2006).

A. Padilha and P. R. Rios, “Decomposition of austenite in austenitic stainless steels,” ISIJ Int., 42(4), 325 – 337 (2002).

H. J. Gabke, “The role of nitrogen in the corrosion of iron and steels,” ISIJ Int., 36(7), 777 – 786 (1996).

M. Janik-Czachor, E. Lunarska, and Z. Szklarska-Smialowska, “Effect of nitrogen content in a 18Cr-5Ni-10Mn stainless steel on the pitting susceptibility in chloride solutions,” Corrosion, 31(11), 394 – 398 (1975).

Yichong Zhang, Moucheng Li, B. Hongvun, et al., “Martensitic transformation behavior and mechanical properties of cold-rolled metastable Cr – Mn – Ni – N austenitic stainless steels,” Mater. Sci. Eng. A, 724, 411 – 420 (2018).

Yafang Han, Tong Liu, and Qiang Zhang, “Effect of different deformation on microstructures and properties in 304HC austenitic stainless steel wire,” Mater. Sci. Forum, 788, 323 – 328 (2014).

A. Kisko, R. D. K. Misra, J. Talonen, and L. P. Karjalainen, “The influence of grain size on the strain-induced martensitic formation in tensile straining of an austenitic 15Cr – 9Mn – Ni – Cu stainless steel,” Mater. Sci. Eng. A, 578, 408 – 416 (2013).

V. Takiris and D. V. Edmonds, “Martensite and deformation twinning in austenitic steels,” Mater. Sci. Eng. A, 273 – 275, 430 – 436 (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 32 – 39, March, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sorokina, S.A., Vorob’ev, R.A., Gorshunov, M.G. et al. Use of Chromium-Manganese Corrosion-Resistant Steel in District Heating Network Applications. Met Sci Heat Treat 65, 159–166 (2023). https://doi.org/10.1007/s11041-023-00908-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00908-z