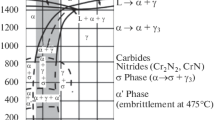

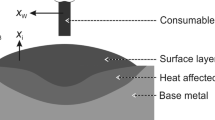

The effect of quenching modes on the structure, phase composition and hardness of austenitic-ferritic stainless steel 20Kh25N8AD3M2 is studied by optical microscopy, x-ray diffraction phase analysis and hardness measurement. Corrosion tests are conducted in a 3% aqueous solution of NaCl with the use of potentiometry and potentiodynamic analysis. Heat treatment modes improving the resistance of steel 20Kh25N8AD3M2 to general and pitting corrosion are suggested. It is shown that aluminum and titanium used to deoxidize the steel can cause pitting corrosion even after quenching.

Similar content being viewed by others

References

B. I. Voronenko, “High-strength castable corrosion-resistant steels of the austenitic-ferritic class,” Liteinoe Proizvod., No. 6, 8 – 13 (1993).

B. I. Voronenko, “Modern corrosion-resistant austenitic-ferritic steels (a review),” Metalloved. Term. Obrab. Met., No. 10, 20 – 29 (1997).

B. I. Arzamasov, T. V. Solov’eva, Yu. A. Puchkov, et al., A Handbook on Structural Materials [in Russian], Izd. MGTU Im. Baumana, Moscow (200), 640 p.

T. V. Svistunova and A. P. Lyamnev, “Development and application of corrosion-resistant steels and alloys,” Metalloved. Term. Obrab. Met., No. 7(661), 9 – 18 (2010).

I. Ya. Sokol, E. A. Ul’yanin, E. G. Feldgandler, et al., Structure and Corrosion of Metals and Alloys, An Atlas [in Russian], Metallurgiya, Moscow (1989), 236 p.

A. P. Shlyamnev, et al., Corrosion-Resistant, High-Temperature and High-Strength Steels and Alloys [in Russian], Intermet Engineering (2000), 233 p.

M. Knyazeva and M. Pohl, “Duplex steels. Pt. 1. Genesis, formation, structure,” Metallogr. Microstruct. Anal., 2, 113 – 121 (2003).

Eleonora Bettini, Ulf Kivisäkk, Christofer Leygraf, and Jinshan Pan, “Study of corrosion behavior of a 2507 super duplex stainless steel: Influence of quenched-in and isothermal nitrides,” J. Electrochem. Sci., 9, 61 – 80 (2014).

B. A. H. Soylu, “Microstructural refinement of duplex stainless steels,” Mater. Sci. Technol., 7(2), 137 – 145 (1991).

J. Charles, “How to improve duplex stainless steel properties with copper addition,” 6th World Duplex Stainless Steels, Venezia, Italy (2000).

O. Smuk, P. Nenonen, H. Yfnnenen, and J. Liimatainen, “Effects of copper on precipitation of secondary phases in duplex stainless steels,” Proc. Int. Conf. “EUROMAT 2000” Microstructure and Properties of Modern P_V Super Duplex Stainless Steels, Elsevier, France, 2(7 – 9), 841 – 846 (2000).

E. A. Dmitriev, E. P. Morgunova, and R. B. Komlyashov, Pumps of Chemical Productions [in Russian], RKhTU Im. D. I. Mendeleeva, Moscow (2013), 48 p.

R. S. Fakhurtdinov, Yu. A. Puchkov, A. G. Degtyareva, and N. S. Moiseeva, “A study of the structure and properties of high-chromium cast irons and stainless steels for chemical production pumps,” Metalloved. Term. Obrab. Met., No. 2, 43 – 49 (2020).

R. S. Fakhurtdinov, Yu. A. Puchkov, S. D. Karpukhin, et al., “Effect of heat treatment on the structure and properties of austenitic-ferritic stainless steel 03Kh24VAD2M3,” Materialovedenie, No. 11, 21 – 29 (2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 9 – 16, March, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fakhurtdinov, R.S., Puchkov, Y.A., Karpukhin, S.D. et al. Heat Treatment of Corrosion-Resistant Austenitic-Ferritic Steel For Immersion Pumps. Met Sci Heat Treat 65, 137–144 (2023). https://doi.org/10.1007/s11041-023-00905-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00905-2