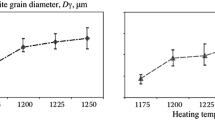

Steels of strength categories K60 and K65 are studied after quenching and tempering in order to choose an optimum heat treatment for rolled sheets, connectors and various pipeline accessories. The chemical compositions of specimens cut from different-thickness sheets from different batches are determined. The structure of the steels is studied after quenching from 800 – 1100°C and tempering at 300 – 750°C. The structure of the steels varies from a ferritic-martensitic one to a coarse acicular martensitic one depending on the quenching temperature. Anomalous refinement of austenite grains is detected in local regions in heating near 1100°C. The hardenability of the steels is shown to be below 20 mm. A mode of quenching and tempering improving the structure and the toughness is suggested for steels K60 and K65.

Similar content being viewed by others

References

Yu. B. Sazonov, A. A. Komissarov, Yu. V. Smirnov, and A. Yu. Sazonova, “Development of heat treatment modes for formation of fine-grained structure,” Metalloved. Term. Obrab. Met., No. 5, 24 – 31 (2009).

Shinjiroh Ueyama, Mineo Niizuma, and Kimitoshi Yonezawa, “Development of high quality heavy plates on steelmaking process at Kimitsu,” in: Works Nippon Steel Technical, August 2013, Report No. 104.

A. N. Zavalishchin, E. V. Kozhevnikova, M. I. Rumyatseva, et al., “Effect of soft reduction on the structure of continuously cast ingot and properties of rolled products from microalloyed steel,” Metallurg, No. 3, 23 – 30 (2019).

E. V. Kozhevnikov, A. N. Zavalishchin, M. I. Rumyantsev, et al., “Influence of “soft” reduction on the structure of continuous cast ingot and the properties of rolled products of microalloyed steels,” Metallurgist, 63(3 – 4), 238 – 248 (2019).

S. V. Denisov, A. N. Zavalishchin, E. V. Kozhevnikova, and M. I. Rumyantsev, “Changes in the structure of low-alloyed steel during production process,” Vest. Magnitogorsk. Gos. Tekh. Univ. Im. G. I. Nosova, No. 3, 51 – 54 (2013).

M. Bekkert and H. Klemm, Methods of Metallographic Etching [Russian translation], Metallurgiya, Moscow (1988), 400 p.

V. M. Chertov, “Detection of actual austenite grains in structural steel,” Metallurg, No. 3, 55 – 56 (2010).

GOST 5657–69. Steel. Method of Testing for Hardenability [in Russian], Izd. Standartov, Moscow, 10 p.

M. Yu. Matrosov, I. V. Lyasotskii, A. A. Kichkina, et al., “Special features of classification of structures of low-carbon low-alloy high-strength pipe steels,” Stal’, No. 1, 65 – 74 (2012).

A. N. Zavalishchin, E. V. Kozhevnikov, O. N. Tulupov, and M. I. Rumyantsev, “Causes of formation of banded structure in steels of strength category K60,” Chern. Met., No. 12, 55 – 60 (2020).

F. Heistercamp, K. Hulka, Yu. I. Matrosov, et al., Niobium-Containing Low-Alloy Steels [in Russian], SP Intermet Engineering, Moscow (1992), 94 p.

L. I. Efron, Metals Science in High Metallurgy [in Russian], Metallurgizdat, Moscow (2012), 696 p.

E. V. Kozhevnikova, S. V. Denisov, and A. N. Zavalishchin, “Structure and properties of steels K60, K65 for cross-country line pipes,” in: Trudy XIX Int. Workshop “TRUBY-2011” [in Russian], RosNITI, Chelyabinsk (2012), Pt. 2, pp. 101 – 107.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 13 – 18, January, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zavalishchin, A.N., Rumyantsev, M.I. & Kozhevnikova, E.V. Effect of Quenching and Tempering on the Structure and Properties of Hot-Rolled Pipe Steels of Strength Categories K60 and K65. Met Sci Heat Treat 65, 12–17 (2023). https://doi.org/10.1007/s11041-023-00884-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00884-4