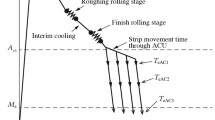

The behavior of low-carbon pipe steel containing 2 and 6 vol.% martensitic-austenitic component in the structure is studied under step forming, expanding and unbending of the pipe using the method of finite-element simulation. The effect of martensitic transformation in the MA-component on the ductility of the steel after processing and unbending of the pipe depending on the volume fraction of the MA-particles in the structure and on the test conditions (the direction of cutting of the samples and the stresses at the start of martensitic transformation) is studied. It is shown that the presence of untransformed austenite in the MA-component can restore partially the ductility of the steel lost due to the plastic deformation during processing of the pipe.

Similar content being viewed by others

References

N. G. Kolbasnikov, S. A. Kuzin, V. S. Teteryatnikov, et al., “Role of martensite-austenite component of bainitic structure in formation of properties of pipe steel. 1. Effect of parameters of TMT,” Metalloved. Term. Obrab. Met., No. 1, 3 – 10 (2022).

N. G. Kolbasnikov, S. A. Kuzin, V. S. Teteryatnikov, et al., “Role of martensite-austenite component of bainitic structure in formation of properties of pipe steel. 2.Deformation and thermal stability of austenite,” Metalloved. Term. Obrab. Met., No. 3, 3 – 12 (2022).

R. Qiang, Z. Tian-xia, J. Zong-chen, et al., “Numerical simulation and paramagnetic study of UOE pipe forming process,” AIP Conf. Proc., 1532(1), 538 (2013).

T. Zou, G. Wu, D. Li, et al., “A numerical method for predicting O-forming gap in UOE pipe manufacturing,” Int. J. Mech. Sci., 98, 39 – 58 (2015).

M. Kainat, S. Adeeb, J. J. Roger Cheng, et al., “Effects of material anisotropy and geometric imperfections on the buckling response of X100 UOE pipes — A finite element study,” in: 3rd Spec. Conf. on Materials Engineering, Montréal, Québec (2013), pp. 109 – 115.

Q. Ren, T. Zou, D. Li, et al., “Numerical study on the X80 UOE pipe forming process,” J. Mater. Proc. Technol., 215, 264 – 277 (2015), pp. 264 – 277.

V. Madhav, H. Krishnaswamy, and S. Majumdar, “Analysis of UOE forming process accounting for Bauschinger effect and welding,” Mater. Manuf. Proc., 35(8), 910 – 921 (2020).

Ndubuaku, M. Martens, J. J. Roger Cheng, and S. Adeeb, “Integrating the shape constants of a novel material stress-strain characterization model for parametric numerical analysis of the deformation capacity of high-strength X80-Grade steel pipelines,” Appl. Sci., 9, 322 (2019).

Z. Dong, Z. Xu,W.Wang, et al., “Numerical simulation and experimental confirmation of a bimetallic pipe forming process,” Materials, 13, 3561 (2020).

J.-x. Yu, M.-x. Han, Y. Yu, et al., “The research on pipe structural behavior of 3D UOE manufacturing process,” Thin-Walled Struct., 158(107168) (2021).

M. T. Kashani, M. Mohareb, M. Asadi, and M. Smith., “Effect of UOE forming process on the buckling strains of steel pipes,” in: Proc. of the 2018 12th Int. Pipeline Conf. IPC2018, Calgary, Alberta, Canada (2018), pp. 96 – 104.

T. Zou, G. Wu, D. Li, et al., “Robust design on UOE forming process based on support vector machine,” Mater. Sci. Forum, 817, 523 – 530 (2015).

S. Yu. Kondrat’ev, O. G. Zotov, G. Ya. Yaroslavskii, et al., “Investigation of interrelationship between damping capacity and mechanical properties as well as morphology of martensite in alloys with reversible martensite transformation,” Prob. Prochn., 14B(3), 79 – 82 (1983).

N. Fontein, Advanced High Strength Sheet Steels Physical Metallurgy, Design, Processing, and Properties, Springer Int. Publ. AG Switzerland is part of Springer Science + Business Media (2015), 396 p.

Radhakanta Rana and Shiv Brat Sigh (eds.), Automotive Steels, Design, Metallurgy and Applications,Woodhead Publishing Series in Metals and Surface Engineering, Woodhead Publ. is an imprint of Elsevier (2017), 469 p.

N. G. Kolbasnikov and S. Yu. Kondrat’ev, Structure. Entropy. Phase Transformations and Properties of Metals [in Russian], SPBU, St. Petersburg (2006), 363 p.

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 12 – 19, October, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kolbasnikov, N.G., Zaitsev, A.M., Adigamov, R.R. et al. Role of Martensite-Austenite Component of Bainitic Structure in Formation of Properties of Pipe Steel. 3. Effect of Martensitic Transformation of Austenite in the MA-Component of Bainite on the Ductility of Steel. Met Sci Heat Treat 64, 547–553 (2023). https://doi.org/10.1007/s11041-023-00849-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00849-7