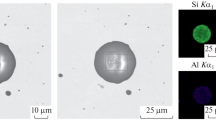

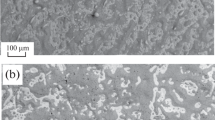

The article presents the results of studies of the structure and non-metallic inclusions of metal surfaced from a flux-cored wire of the Fe – C – Si – Mn – Cr – Ni – Mo – V system. In the composition of the wire charge, instead of amorphous carbon, gas cleaning dust of aluminum production containing carbon and fluorine was introduced. Surfacing from a flux-cored wire with a diameter of 5 mm on plates made of St3 steel under AN-26S flux was carried out using a welding machine at a current of 420 – 520 A, a voltage of 28 – 32 V, a welding rate of 7.2 – 9 m/h with cooling at room temperature. The properties of two samples with different content of the carbon-fluorine-containing additive in a flux-cored wire have been studied. The grain size and martensite dispersion in the structure of the surfaced layer have been determined. The analysis of the chemical composition of the surfaced layer and non-metallic inclusions generated in it has been carried out. The hardness of the samples has been measured by the Rockwell method. It has been concluded that it is necessary to establish the optimal amount of the carbon-fluorine-containing additive in the flux-cored wire in order to avoid the formation of an increased amount of non-metallic inclusions in the surfaced layer.

Similar content being viewed by others

References

B. E. Paton (ed.), Technology of Electric Fusion Welding of Metals and Alloys [in Russian], Metallurgiya, Moscow (1974).

I. V. Osetkovskiy, N. A. Kozyrev, A. I. Gusev, et al., “Influence of the cobalt additive on the flux cored wire of system Fe – C – Si – Mn – Cr – Ni – Mo – V,” Key Eng. Mater., 736, 63 – 67 (2017).

N. A. Kozyrev, N. V. Kibko, A. A. Umanskii, et al., “New C – Si – Mn – Cr – V – Mo powder wires for roller surfacing,” Steel Transl., 46(10), 711 – 717 (2016).

A. I. Gusev, N. A. Kozyrev, I. V. Osetkovskiy, et al., “Quality of metal deposited flux cored wire with the system Fe – C – Si – Mn – Cr – Mo – Ni – V – Co,” Key Eng. Mater., 736, 23 – 28 (2017).

A. I. Gusev, N. A. Kozyrev, I. V. Osetkovskiy, et al., “Quality of metal deposited flux cored wire with the system Fe – C – Si – Mn – Cr – Mo – Ni – V – Co,” IOP Conf. Ser.: Mater. Sci. Eng., 253, 1 – 6 (2017).

A. I. Gusev, N. A. Kozyrev, A. A. Usoltsev, et al., “Study of the properties of flux cored wire of Fe – C – Si – Mn – Cr – Mo – Ni – V – Co system for the strengthening of nodes and parts of equipment used in the mineral mining,” IOP Conf. Ser.: Earth Env., 84, 1 – 8 (2017).

N. A. Kozyrev, D. A. Titov, S. N. Starovatskaya, et al., “Influence of introducing a carbon-fluorine-containing additive and nickel into the charge for the production of flux-cored wire of the C – Si – Mn – Cr – V – Mo system,” Izv. Vysh. Uchebn. Zaved., Chern. Metallurg., 57(4), 34 – 37 (2014).

A. I. Gusev, N. A. Kozyrev, N. V. Kibko, et al., “Influence of introduction of tungsten and chromium on properties of metal surfaced with a cored wire of the Fe – C – Si – Mn – Mo – Ni – V – Co system,” Zagot. Proizvod. Mashinostr., 17(2), 56 – 60 (2019).

N. A. Kozyrev, N. V. Kibko, A. A. Umanskii, and D. A. Titov, “Influence of nickel and carbon-fluorine containing additives on the structure and properties of deposited steel 25Kh5FMS,” Aktual. Probl. Mashinostr., No. 3, 54 – 59 (2015).

N. A. Kozyrev, A. A. Usoltsev, A. N. Prudnikov, et al., “Study of properties of cored wire based on ferrochrome gas-cleaning dust,” Chern. Metallurg., Byul. Nauchn. Tekhn. Ekonom. Inform., 75(3), 365 – 372 (2019).

N. A. Kozyrev, A. I. Gusev, G. V. Galevskii, et al., Russian Federation Patent 2641590, IPC 8 V23 K35/36, Cored Wire [in Russian], Siberian State Industrial University, Novokuznetsk (2016).

A. A. Umanskii, N. A. Kozyrev, A. R. Mikhno, et al., Russian Federation Patent 2726230, IPC 8 V23 35/368, Cored Wire [in Russian], Siberian State Industrial University, Novokuznetsk (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 29 – 35, June, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Osetkovskiy, I.V., Yunusov, A.M., Kozyrev, N.A. et al. Investigation of the Microstructure of Surfaced Layer from Flux-Cored Wire of the Fe – C – Si – Mn – Cr – Ni – Mo – V System. Met Sci Heat Treat 64, 321–327 (2022). https://doi.org/10.1007/s11041-022-00808-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00808-8