Aspects of obtaining electrodes with a coating containing tungsten nanopowder are considered along with their modes of utilization for surfacing purposes. The rheological properties of an aqueous alkaline solution of potassium silicate used for applying tungsten nanopowder to electrodes are determined. The stability of the surfacing process is investigated in terms of the structure of the metal deposited with coated electrodes. It is confirmed that coating electrodes with tungsten nanopowder can be used to derive a stable process of transferring droplets of electrode metal into the melt bath and modifying the deposited metal by influencing the viscosity of the coating of combined electrodes.

Similar content being viewed by others

References

Market of Welding Electrodes in Russia. Current Situation and Forecast for 2021 – 2025. In Marketing Research and Market Review in Russia 2021. https://alto-group.ru/otchot/rossija/333-rynok-svarochnyh-jelektrodov-v-rossii-tekuschaja-situacijai- prognoz-2020-2024-gg.html)

A. A. Mazur, S. V. Pustovoit, O. K. Makovetskaya, et al., “Status and prospects of the world and regional markets for welding materials (Review),” Avtomat. Svarka, No. 11(737), 39 – 45 (2014).

V. G. Lozovoy, V.M. Dzyuba, O. V. Dzyuba, et al., “Russian import-substituting electrodes LB-52TRU for welding and repair of main oil and gas pipelines,” Svarka Diagnost., No. 1, 22 – 23 (2007).

M. P. Shalimov and E. B. Votinova, “Calculation and experimental method for assessing the parameters of the transition of elements into the weld metal during arc welding and improving the composition of the charge of the flux-cored wire,” Vest. Permsk. Nats. Issled. Politeh. Univer. Mashinostr., Materialoved., 21(1), 28 – 35 (2019).

Y. V. Chekanova, Y. G. Bychenya, A. I. Nikolaev, et al., “New approach to obtaining finely dispersed simple and complex oxides as functional materials for welding purposes,” Russ. J. Appl. Chem., 87(12), 1829 – 1835 (2014).

D. Il’yashenko and S. Makarov, “Chapter 13. Production of electrodes for manual arc welding with using the complex modifiers,” in: Applied Nanotechnology: Materials and Applications (2016), pp. 207 – 211.

M. A. Kuznetsov, D. P. Iljyashchenko, E. V. Lavrova, et al., “Study of the influence of nanostructured powders on the character of the transfer of electrode metal and the structure formation process of surfaced metal,” J. New Tech. Mater., 11(2), 35 – 41 (2021).

C. Wang, M. Wang, J. Shi, et al., “Effect of microstructural refinement on the toughness of low carbon martensitic steel,” Scr. Mater., 58(6), 492 – 495 (2008).

S. B. Sapozhkov and E. M. Burakova, “The study of complex (Ti, Zr, Cs) nanopowder influencing the effective ionization potential of arc discharge when mma welding,” IOP Conf. Ser.: Mater. Sci. Eng., 142(1), 012018 (2016).

G. H. Sokolov, A. S. Troshkov, V. I. Lysak, et al., “Influence of nanodispersed WC and nickel carbides on the structure and properties of the deposited metal,” Svarka Diagnost., No. 3, 36 – 38 (2011).

M. A. Kuznetsov and E. A. Zernin, “Nanotechnologies and nano-materials in welding production (Review),” Welding Int., 26(4), 311 – 313 (2012).

Ultrasonic Laboratory Devices and Industrial Installations. UIP1000hd [Electronic resource]: access mode: http://www.ultrazvuc.ru/product/products type id/2/products id/9. Accessed 11.12.2021.

Ultrasonic Laboratory Devices and Industrial Installations. Production of Nanomaterials [Electronic resource]: access mode: http://www.ultrazvuc.ru/industrie/industries areaes id/2/industrieses id/4. Accessed 11.12.2021.

D. P. Il’Yaschenko, D. A. Chinakhov, S. V. Makarov, et al., “Effect of ultra-disperse powder in electrode coating on properties of welds in MMA welding,” Eng. Solid Mech., 8(1), 41 – 48 (2020).

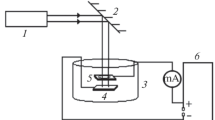

E. A. Zernin and K. I Tomas, “Automated method for studying the coating process,” Inzh. Vest. Dona, No. 2 (part 2), 1 – 5 (2015).

Y. N. Saraev, D. A. Chinakhov, D. I. Ilyashchenko, et al., “Investigation of the stability of melting and electrode metal transfer in consumable electrode arc welding using power sources with different dynamic characteristics,” Welding Int., 31(10), 784 – 790 (2017).

A. A. Erokhin, Fundamentals of Fusion Welding. Physical and Chemical Laws [in Russian], Leningrad, Mashinostroenie (1973).

C. T. Vaz and A. Q. Bracarense, “The effect of the use of PTFE as a covered-electrode binder on metal transfer,” Soldagem & Inspeqao, 20(2), 160 – 170 (2015).

V. Varnauskas, V. Rudzinskas, and O. Èernaðëjus, “Influence of covering components of welding electrodes on chemical composition and mechanical properties of fused metal,” Mater. Sci., 10(1), 7 – 10 (2004).

V. Laziæ, D. Milosavljeviæ, S. Aleksandroviæ, et al., “Carbide type influence on tribological properties of hard-faced steel layer. Part I: theoretical considerations,” Tribology in Industry, 32(2), 11 – 20 (2010).

M. A. Kuznetsov, E. A. Zernin, G. V. Shlyakhova, et al., “Microstructure of welded joints obtained using aluminum oxohydroxide nanopowders,” Svarka Diagnost., No. 4, 24 – 26 (2016).

S. A. Barannikova, G. V. Shlyakova, E. A. Zernin, et al., “Optimal concentration of nanostructured powder in protective gas,” Steel Transl., 47(4), 241 – 244 (2017).

M. A. Kuznetsov, V. I. Danilov, M. A. Krampit, et al., “Mechanical and tribological properties of a metal wall grown by an electric arc method in an atmosphere of shielding gas,” Metal Working Mater. Sci., 22(3), 18 – 32 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 43 – 49, May, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zernin, E.A., Ilyashenko, D.P., Danilov, V.I. et al. Effect of Tungsten Nanopowder Content on Electrode Coating Properties and the Structure of the Deposited Metal. Met Sci Heat Treat 64, 285–291 (2022). https://doi.org/10.1007/s11041-022-00802-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00802-0