The kinetics of high-temperature nitriding and changes in the structure and properties of heat-resistant Ni – Co – Cr – W – Ti nickel alloy VZh171 depending on its duration were studied. Short-term pulling and long-term strength tests were carried out. An analysis of the microstructure of a nitrided case is presented along with a mathematical description of the process. Recommendations are given for determining the optimal nitriding conditions of the VZh171 alloy in order to achieve the highest short-term and long-term strength. The established dependencies allow the nitriding time during the course of manufacturing items of various thicknesses from the VZh171 alloy to be determined.

Similar content being viewed by others

References

E. N. Kablov, Trends and Guidelines of Innovative Development in Russia: Collection Volume of Scientific and Informational Materials [in Russian], VIAM, Moscow (2015).

E. N. Kablov, O. G. Ospennikova, B. S. Lomberg, and V. V. Sidorov, “Priority directions for developing technologies for production of refractory materials for aircraft engine building,” Probl. Cher. Met. Mater., No. 3, 47 – 54 (2020).

E. N. Kablov, “There is no future without new materials,” Metallurg, 12, 4 – 8 (2013).

B. S. Lomberg, S. V. Hovsepyan, M. M. Bakradze, et al., “Use of new deformable nickel alloys for advanced gas turbine engines,” Aviats. Mater. Tekh., No. S, 116 – 129 (2017) (DOI: https://doi.org/10.18577/2071-9140-2017-0-S-116-129).

Yu. G. Bykov, S. V. Ovsepyan, I. S. Mazalov, and A. S. Romashov, “Use of a new heat-resistant VZh alloy in a promising engine design,”, Vestn. Dvigatelestroyen., No. 2(27), 246 – 250 (2012).

M. V. Akhmedzyanov, A. V. Skugorev, S. V. Ovsepyan, and I. S. Mazalov, “Development of resource-saving technology for producing cold-rolled sheet from high-heat-resistant welded VZh171 alloy,” Proizvod. Prokata, 1, 14 – 17 (2015).

M. G. Fahrmann, V P. Deodeshmukh, and S. K. Srivastava, “HAYNES NS-163 alloy—a novel nitride dispersion strengthened co-base alloy,” in: ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Germany (2014).

V. I. Lukin, V. G. Kovalchuk, E. V. Golev, et al., “Welding of heat-resistant VZh171 nickel alloy hardened by internal nitriding,” Nov. Mater., Nauka Tekh., No. 5, 1 – 11 (2014).

O. Yu. Kozlova, S. V. Ovsepyan, A. S. Pomelnikova, and M. V. Akhmedzyanov, “Influence of austenitic nitriding on structure and properties of welded heat-resistant nickel alloys,” Vestn. MGTU im. N. É. Baumana, Mashinostroenie, No. 6, 33 – 42 (2016).

B. S. Lomberg, D. V. Kapitanenko, I. S. Mazalov, and M. V. Bubnov, “Technological parameters of manufacturing parts by cold stamping using sheet metal of heat-resistant VZh159 and VZh171 and high-strength VZh172 alloys,” Kuznech.-Shtamp. Proizvod., No. 8, 14 – 19 (2015).

V. S. Denisova, G. A. Malinina, O. V. Vlasova, and A. Yu. Vinogradova, “Effect of silicon tetraboride additives on properties of heat-resistant coatings for protection of heat-resistant nickel alloys,” Aviats. Mater. Tekh., No. 2, 68 – 73 (2019) (DOI: https://doi.org/10.18577/2071-9140-2019-0-2-68-73).

L. I. Kuksenova, S. A. Gerasimov, M. S. Alekseeva, and V. I. Gromov, “Influence of vacuum chemical-thermal treatment on wear resistance of VKS-7 and VKS-10 steels,” Aviats. Mater. Tekh., No. 1, 3 – 8 (2018) (DOI: https://doi.org/10.18577/2071-9140-2018-0-1-3-8).

L. G. Petrova, “Current developmental trends of theory and practice of steel nitriding processes,” Metall. Mashinostr., No. 4, 40 (2011).

L. G. Petrova and O. V Chudina, “Applying management method of structure formation for development of strengthening technologies,” Metalloved. Term. Obrab. Met., No. 5, 31 – 41 (2010).

L. G. Petrova, “Physicochemical characteristics of internal nitriding of multicomponent alloys,” Met. Sci. Heat Treat., 37(1–2), 41 – 47 (1995).

K. Ts. Din and M. Yu. Semenov, “Forecasting saturation and strength properties of nitrided case of 40XN-VI nickel alloy on the basis of calculation methods,” Metallurg, No. 9, 109 – 113 (2017).

L. E. Kindlimann and G. S. Ansell, “Kinetics of the internal nitridation of austenitic Fe – Cr – Ni – Ti alloys,” Metal. Trans., 1(1), 163 – 170 (1970).

U. Krupp and H.-J. Christ, “Internal nitridation of nickel-base alloys. Part I. Behavior of binary and ternary alloys of the Ni – Cr – Al – Ti system,” Oxid. Met., 52, 277 – 298 (1999).

M. Fahrmann and S. K. Srivastava, “Nitridation of HAYNES/NS-163_ alloy: thermodynamics and kinetics,” JOM, 64(2), 280 – 287 (2012).

M. V. Akhmedzyanov, S. V. Ovsepyan, O. I. Rastorgueva, and E. A. Davydova, “Influence of alloying elements on heat resistance of deformable Ni – Co alloys following nitride hardening,” Corros. Mater. Protec., No. 12, 21 – 25 (2015).

A. A. Kodentsov, J. H. Golpen, C. Cserhati, et al., “High-temperature nitridation of Ni – Cr alloys,” Metall. Mater. Trans., 27A, 59 – 69 (1996).

J. J. Barnes and G. Y. Lai, “Factors affecting the nitridation behavior of Fe-base, Ni-base and Co-base alloys in pure nitrogen,” J. Phys. Colloq. C9, 3 (12), 176 (1993).

L. M. Pike, 100+ years of wrought alloy development at Haynes international,” in: 8th International Symposium on Superalloy 718 and Derivatives, TMS (2014), pp. 15 – 30.

Yu. M. Lakhtin, Ya. D. Kogan, G.-I. Shpis, and Z. Bemer, Theory and Technology of Nitriding [in Russian], Moscow, Metallurgiya (1991).

M. Udyavar and D. J. Young, “Precipitate morphologies and growth kinetics in the internal carburization and nitridation of Fe – Ni – Cr alloys,” Corros. Sci., 42, 861 – 883 (2000).

H. J. Christ, S. Y. Chang, and U. Krupp, “Thermodynamic characteristics and numerical modeling of internal nitridation of nickel base alloys,” Corros. Mater., 54(11), 887 – 895 (2003).

S. S. Kiparisov and Yu. V. Levinsky, Nitriding of Refractory Materials [in Russian], Moscow, Metallurgiya (1972).

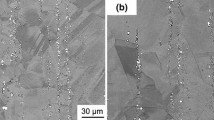

S. V. Hovsepyan, B. S. Bokshtein, M. V. Akhmedzyanov, et al., “Kinetics of nitride particle growth during high-temperature volumetric nitriding of a deformable Ni – Co – Cr – W – Ti alloy,” Materialovedenie, No. 6, 21 – 25 (2014).

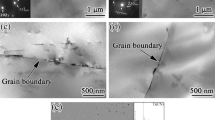

S. V. Ovsepyan, E. A. Lukina, E. V. Filonova, and I. S. Mazalov, “Formation of a strengthening phase during high-temperature nitriding of a welded heat-resistant deformable Ni – Co – Cr alloy,” Aviats. Mater. Tech., No. 1, 3 – 8 (2013).

E. A. Lukina, S. V. Ovsepyan, E. A. Davydova, and M. V. Akhmedzyanov, “Structural characteristics of a heat-resistant Ni – Co – Cr alloy strengthened by internal nitriding,” Tzvetn. Met., No. 7, 76 – 82 (2016) (DOI: https://doi.org/10.17580/tsm.2016.07.10).

B. S. Bokstein, Diffusion in Metals [in Russian], LENAND, Moscow (2019).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 45 – 49, April, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akhmedzyanov, M.V., Ovsepyan, S.V., Rodin, A.O. et al. Kinetics of Austenitic Nitriding and Properties of Ni – Co – Cr – W – Ti Alloy. Met Sci Heat Treat 64, 231–235 (2022). https://doi.org/10.1007/s11041-022-00790-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00790-1