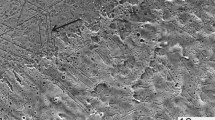

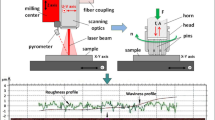

The methods of optical and electron microscopy are used to study the relation between the processes of scale formation and propagation of surface cracks in TiAl alloys under heat treatment. It is shown that cracks propagate during post-treatment cooling in the oxide layer on the surface of the alloy, and the probability of their formation decreases in the case of tight adhesion of the scale to the metal due to enhancement of the surface smoothens. Control of the thickness of the scale formed in cooling of the alloy and its removal are important factors for preventing surface cracks arising in the heat treatment of the TiAl alloy.

Similar content being viewed by others

References

A. Chlupova, M. Heczko, K. Obrtlik, et al., “Effect of heattreatment on the microstructure and fatigue properties of lamellar γ-TiAl alloyed with Nb, Mo and/or C,” Mater. Sci. Eng. A, 786, 139427 (2020).

S. Bolz, M. Oehring, J. Lindemann, et al., “Microstructure and mechanical properties of a forged β-solidifying γ TiAl alloy in different heat treatment conditions,” Intermetallics, 58, 71 – 83 (2015).

X. Li, H. Xu,W. Xing, et al., “Phase transformation behavior of a β-solidifying γ-TiAl-based alloy from different phase regions with various cooling methods,” Metals, 8, 731 (2018).

K. Choi, J. Kim, J. Park, and Y. Kim, “Microstructural evolution in cast and HIP’ed ingot material of beta gamma TiAl alloy by two step cooling,” Korea J. Met. Mater., 56(5), 335 – 341 (2018).

C. Lang and M. Schutze, “The initial stage in the oxidation of TiAl,” Oxid. Intermet., 245 – 263 (1997).

W. Lu, F. Wang, and C. Chen, “Effect of niobium on the oxidation behavior of TiAl,” J. Mater. Res., 22(6), 1486 – 1490 (2007).

J. Malecka, “Oxidation activation energy of titanium alloy based on TiAl(γ) intermetallic phase,” Adv. Mater. Sci., 18(2), 56 – 61 (2018).

P. Ouyang, G. Mi, P. Li et al, “Non-isothermal oxidation behaviors and mechanisms of Ti – Al intermetallic compounds,” Materials, 12, 2114 (2019).

A. Rahmel, W. Quadakkers, and M. Schutze, “Fundamentals of TiAl oxidation – A critical review,” Mater. Corros., 46, 271 – 285 (1995).

A. Banu, M. Marcu, S. Petrescu, et al., “Effect of niobium alloying level on the oxidation behavior of titanium aluminides at 850°C,” Int. J. Minerals, Metall. Mater., 23(12), 1452 – 1457 (2016).

G. Deng, K. Nagamoto, Y. Nakano, and T. Nakanishi, “Evaluation of the effect of surface roughness on crack initiation life,” in: 12th Int. Conf. on Fracture (2009).

D. Serafin, W. Nowak, and B. Wierzba, “Differences in oxides morphology as a result of surface preparation of NiFe alloy,” Surf. Coat. Technol., 385, 125421 (2020).

N. Thiyaneshwaran, K. Sivaprasad, and B. Ravisankar, “Nucleation and growth of TiAl3 intermetallic phase in diffusion bonded Ti/Al metal intermetallic laminate,” Sci. Rep., 8, 16797 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 13 – 17, August, 2021.

Rights and permissions

About this article

Cite this article

Yang, H., Jung, WC., Lee, C. et al. Effect of Surface Smoothness on the Structure of Scale and Formation of Surface Cracks in TiAl Alloys under Heat Treatment. Met Sci Heat Treat 63, 414–418 (2021). https://doi.org/10.1007/s11041-021-00704-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00704-7