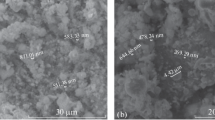

The characteristics of the wear resistance of samples sintered from electroerosion high-chromium powders obtained in illuminating oil are determined for a friction path of 500 m. It is shown experimentally that the rider is partially worn and covered with the products of wear of the sample. The length of the wear track of the sample is 383.1 – 473.5 μm; the depth of the wear groove on the surface is 5 μm; the friction factor on the surface of the sample is 0.228 – 0.826; the wear factors for the rider from stainless steel AISI 420 and for the sample from sintered steel 12Kh17 are 0.016 and 1.138, respectively.

Similar content being viewed by others

References

Yu. G. Dorofeev, V. Yu. Dorofeev, A. V. Babets, et al., “Special features of contact interaction on the interface of layers of hot-formed powder bimetal of type ‘structural steel – high speed steel’,” Izv. Vyssh. Ucheb. Zaved., Poroshk. Metall. Funkts. Pokr., No. 3, 11 – 22 (2018).

I. P. Borodin, Yu. S. Shatov, V. Yu. Shiryaev, et al., “Structure and properties of ‘steel 45 – powder steel ASP2005’ composite formed by explosion energy,” Metalloved. Term. Obrab. Met., No. 8(674), 8 – 11 (2011).

V. G. Shishka, A. V. Skorikov, I. V. Ivanova, and I. V. Shishka, “Choice of alloying elements for improving the machinability of powder structural steels,” Inzh. Vest. Dona, No. 4(51), 11 (2018).

Zh. V. Eremeeva, N. M. Nitkin, and G. Kh. Sharipzyanova, “Special features of application of nanosize carbon and chromium powders in processes of blend preparation and pressing of powder steels,” Izv. MGTU MAMI, No. 2(12), 123 – 127 (2011).

T. V. Vysotskii and V. T. Vysotskii, “Processes of production of alloyed powder steels and articles from them,” Izv. Belarus.-Ross. Univ., No. 3(20), 58 – 65 (2008).

V. I. Kostikov, Zh. V. Eremeeva, S. I. Rupasov, et al., “Heat treatment of powder hot-deformed steels alloyed with nanosize carbon and chromium,” Materialovedenie, No. 1, 51 – 55 (2012).

V. L. Girshov, V. N. Tsemenko, and S. A. Mazurov, “A study of the effect of structural defects on the strength of powder high-speed steels,” Nauch.-Tekh. Vedom. St.- Peterburg. Gos.Politekh. Univ., No. 3(130), 175 – 180 (2011).

V. N. Antsiferov, L. M. Grevnov, M. F. Torsunov, and V. A. Boyarshinov, “Structure of fullerene-containing deformed powder steels,” Izv. Vyssh. Ucheb. Zaved., Poroshk. Metall. Funkts. Pokr., No. 3, 7a – 11 (2012).

V. K. Narva, A. V. Morants, and Zh. A. Sentyurina, “A study of the process of laser cladding of ‘steel – titanium carbide’ powder mixtures onto a steel substrate,” Izv. Vyssh. Ucheb. Zaved., Poroshk. Metall. Funkts. Pokr., No. 4, 25 – 31 (2012).

L. N. D’yachkova and L. F. Kerzhentseva, “Activation of the process of sintering of powder carbon steels,” Izv. Vyssh. Ucheb. Zaved., Poroshk. Metall. Funkts. Pokr., No. 4, 32 – 37 (2012).

V. N. Antsiferov, V. Ya. Bulanov, Yu. G. Gurevich et. al., “A study of decomposition of supercooled austenite of powder steels by a novel digital magnetometer,” Metalloved. Term. Obrab. Met., No. 4(598), 24 – 29 (2005).

S. I. Bogodukhov, “Strengthening of powder steels with the use of rapid heating,” Mashinostroitel’, No. 10, 38 – 40 (1999).

V. N. Kornopol’tsev, “Intensification of processes of boronizing of carbon steels with powder mixtures,” Fund. Probl. Sovr. Materialoved., 10(2), 266 – 271 (2013).

Yu. G. Dorofeev, S. S. Mikhailenko, A. V. Babets, et al., “Effect of thermochemical treatment on the structure and properties of low-alloy powder steels,” Izv. Vyssh. Ucheb. Zaved., Sev.-Kavkaz.Reg., Tekh. Nauki, No. 5, 37 – 40 (2004).

E. V. Ageev and R. A. Latypov, “Fabrication and investigation of carbide billets from powders prepared by electroerosive dispersion of tungsten-containing wastes,” Russian J. Non-Ferr. Met., 55(6), 577 – 580 (2014).

R. A. Latypov, G. R. Latypova, E. V. Ageev, et al., “Elemental composition of the powder particles produced by electric discharge dispersion of the wastes of a VK8 hard alloy,” Russian Metall. (Metaly), 2017(12), 1083 – 1085 (2017).

R. A. Latypov, G. R. Latypova, E. V. Ageev, et al., “Properties of the coatings fabricated by plasma-jet hard-facing by dispersed mechanical engineering wastes,” Russian Metall. (Metally), 2018(6), 573 – 575 (2018).

E. V. Ageev and R. A. Latypov, “Fabrication and investigation of hard alloy billets from powders obtained by electroerosion dispersion of tungsten-containing wastes,” Izv. Vyssh. Ucheb. Zaved., Tsvetn. Metall., No. 5, 50 – 53 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 53 – 57, July, 2021.

Rights and permissions

About this article

Cite this article

Ageev, E.V., Ageeva, E.V. & Sysoev, A.A. Assessment of the Wear Resistance of Samples Sintered from Electroerosion High-Chromium Powders Produced in Illuminating Oil. Met Sci Heat Treat 63, 396–399 (2021). https://doi.org/10.1007/s11041-021-00701-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00701-w