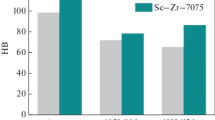

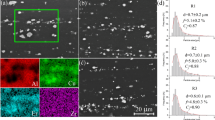

The effect of Er and Zr microadditions on changes in the structure of aluminum alloy 7075 during homogenization is studied. Additions of Er and Zr cause grain refinement and reduce the size of coarse nonequilibrium grain-boundary eutectic. Eutectic dissolves completely during the homogenization process; long rods are transformed into spherical particles. Homogenization regime substantially affects secondary Al3(Er, Zr) phase precipitation. Two-stage homogenization (400°C, 12 h + 465°C, 12 h) leads to fine and uniformly distributed particles of Al3 (Er, Zr) with an average radius of 28.9 nm and volume fraction of 1.3 ×10–3.

Similar content being viewed by others

Notes

Alloy 7075 with additions of Er and Zr is designated 7075E in tables and figures.

References

J. Li, F. Li, X. Ma, et al., “Effects of heat treatment on microstructure and mechanical properties of an ECAPed Al – Zn – Mg – Cu alloy,” Adv. Eng. Mater., 1701155 (2018).

T. F. Chung, M. Kawasaki, P. Wang, et al., “Atomic-resolution energy dispersive x-ray spectroscopy mapping of η precipitates in an Al – Mg – Zn – Cu alloy,” Mater. Charact., 166, 110448 (2020).

Z. H. Zhang, J. Xue, Y. G. Jiang, and F. Jin, “Effect of pre-annealing treatment on the microstructure and mechanical properties of extruded Al – Zn – Mg – Cu alloy bars,” Int. J. Miner. Metall. Mater., 24(11), 1284 – 1292 (2017).

O. A. Chikova, V. M. Zamyatin, and B. V. Ovsyannikov, “Special features of the structure of plates from an alloy of the Al – Mg – Zn – Cu system,” Metal Sci. Heat Treat., 56(1), 18 – 20 (2014).

J. D. Robson, “Optimizing the homogenization of zirconium containing commercial aluminum alloys using a novel process model,” Mater. Sci. Eng. A, 338, 219 – 229 (2002).

D. C. Dorward and D. J. Beernsen, “Grain structure and quench rate effects on strength and toughness of AA7050 Al – Mg – Zn – Cu – Zr alloy,” Metall. Trans., 26(9), 2481 – 2484 (2003).

V. V. Zakharov and I. A. Fisenko, “Effect of homogenization on the structure and properties of alloy of the Al – Zn – Mg – Sc – Zr system,” Metal Sci. Heat Treat., 60(6), 354 – 359 (2018).

Y. F. Dong, B. H. Ren, K. Wang, et al., “Effects of graphene addition on the microstructure of 7075Al,” Mater. Res. Express, 7, 026510 (2020).

Wang Y. C., Wu X. D., Cao L. F. et al. “Effect of trace Er on the microstructure and properties of Al – Mg – Zn – Cu – Zr alloys during heat treatments,” Mater. Sci. Eng. A, 792, 139807 (2020).

H. Fang, H. Chao, and K. Chen, “Effect of Zr, Er and Cr additions on microstructures and properties of Al –Mg – Zn – Cu alloys,” Mater. Sci. Eng. A, 610, 10 – 16 (2014).

H. Li, Z. Gao, H. Yin, et al., “Effects of Er and Zr additions on precipitation and recrystallization of pure aluminum,” Scr. Mater., 68, 59 – 62 (2013).

S. Wen, K. Gao, Y. Li, et al., “Synergetic effect of Er and Zr on the precipitation hardening of Al – Er – Zr alloy,” Scr. Mater., 65, 592 – 595 (2011).

H.Wu, S.Wen, H. Huang, et al., “Effects of homogenization on precipitation of Al3 (Er, Zr) particles and recrystallization behavior in a new type Al – Zn – Mg – Er – Zr alloy,” Mater. Sci. Eng. A, 689, 313 – 322 (2017).

G. F. Xu, S. Z. Mou, J. J. Yang, et al., “Effect of trace rare earth element Er on Al – Zn – Mg alloy,” Trans. Nonfer. Met. Soc. China, 16, 598 – 603 (2006).

Z. G. Wu, M. Song, and Y. H. He, “Effects of Er on the microstructure and mechanical properties of an as-extruded Al – Mg alloy,” Mater. Sci. Eng. A, 504, 183 – 187 (2009).

Y. Wang, S. Zhang, R. Wu, et al., “Coarsening kinetics and strengthening mechanisms of core-shell nanoscale precipitates in Al – Li – Yb – Er – Sc – Zr alloy,” J. Mater. Sci. Technol., 61, 197 – 203 (2021).

H. Wu, S. P. Wen, J. T. Lu, et al., “Microstructural evolution of new type Al – Mg – Zn – Cu alloy with Er and Zr additions during homogenization,” Trans. Nonfer. Met. Soc. China, 27, 1476 – 1482 (2017).

H. C. Fang, H. Chao, and K. H. Chen, “Effect of Zr, Er and Cr additions on microstructures and properties of Al – Mg – Zn – Cu alloys,” Mater. Sci. Eng. A, 610, 10 – 16 (2014).

Y. C. Huang, C. C. Zhang, Y. L. Ma, and Y. Liu, “Effects of homogenization on the dissolution and precipitation behavior of intermetallic phase for a Zr and Er containing Al – Mg – Zn – Cu alloy,” Prog. Nat. Sci. Mater., 30, 47 – 53 (2020).

E. Nes, N. Ryum, and O. Hunderi, “On the Zener drag,” Acta Metall., 33, 11 – 22 (1985).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 22 – 27, June, 2021.

Rights and permissions

About this article

Cite this article

Leng, J., Ren, B., Zhao, J. et al. Effect Er and Zr Microalloying on Aluminum Alloy 7075 Microstructure Formation During Homogenization. Met Sci Heat Treat 63, 312–317 (2021). https://doi.org/10.1007/s11041-021-00688-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00688-4