Metallographic studies and tests for abrasive wear resistance are performed for a Ni – Cr – B – Si coating obtained by laser powder cladding with the help of a multichannel (40 beams) CO2 laser. Efficiency of repeated laser recrystallization of the surface layers of the coating is demonstrated. This treatment can be used to form structures with different values of dendritic parameter and affects positively the wear resistance of the coating. The wear characteristics are shown to depend linearly on the dendritic parameter, which may be used as a criterion of wear resistance of coatings.

Similar content being viewed by others

References

A. G. Grigor’yants, I. N. Shiganov, and A. I. Misyurov, Procedures of Laser Treatment [in Russian], MGTU, Moscow (2006), 664 p.

R. A. Savray, A. V. Makarov, N. N. Soboleva, et al., “Contact endurance of NiCrBSi coatings deposited by gas-powder cladding,” Obrab. Met. (Tekhnol., Oborud., Instr.), No. 4, 43 – 51 (2014).

R. N. Koreshkov, V. N. Petrovskii, P. S. Dzhumaev, and V. I. Pol’skii, “Technological features of formation of structure of laser claddings with the use of radiation of powerful fiber lasers,” Metalloved. Term. Obrab. Met., No. 5, 30 – 34 (2014).

V. I. Yugov, L. E. Afanas’ev, and M. V. Novoselova, “Special features of formation structure and microgeometry of the surface of laser claddings with the use of multichannel CO2-laser,” Uproch. Tekhnol. Pokr., No. 11(143), 19 – 22 (2016).

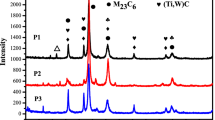

L. E. Afanas’eva and G. V. Ratkevich, “Laser cladding of NiCrBSiFe–WC coating with the help of a multichannel laser,” Pis’ma Mater., 8[3(31)], 268 – 273 (2018).

M. J. Tobar, C. Álvarez, J. M. Amado, et al., “Morphology and characterization of laser clad composite NiCrBSi–WC coatings on stainless steel,” Surf. Coat. Technol., 200, 6313 – 6317 (2006).

A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “Formation of wear-resistant chromium-nickel coating with extra-high level of heat resistance by combined laser and heat treatment,” Metalloved. Term. Obrab. Met., No. 3(717), 39 – 46 (2015).

S. Houdková, E. Šmazalová, M. Vostřák, and J. Schubert, “Properties of NiCrBSi coating, as sprayed and remelted by different technologies,” Surf. Coat. Technol., 253, 14 – 26 (2014).

N. Serres, F. Hlawka, S. Costil, C. Langlade, and F. Machi, “Microstructures of metallic NiCrBSi coatings manufactured via hybrid plasma spray and in situ laser remelting process,” J. Thermal Spray Technol., 20(1 – 2), 336 – 343 (2011).

Z. Bergant and J. Grum, “Quality improvement of flame sprayed, heat treated, and remelted NiCrBSi coatings,” J. Thermal Spray Technol., 18(3), 380 – 391 (2009).

L. E. Afanas’eva, “Microstructure of NiCrBSi coating after laser cladding and subsequent laser melting,” Metalloobrabotka, No. 3, 34 – 38 (2018).

B. M. Dhakar, D. K. Dwivedi, and S. P. Sharma, “Studies on remelting of tungsten carbide and rare earth modified nickel base alloy composite coating,” Surf. Eng., 28(1), 73 – 80 (2012).

S. Stewart, R. Ahmed, and T. Itsukaichi, “Rolling contact fatigue of post-treated WC-NiCrBSi thermal spray coatings,” Surf. Coat. Technol., 190(2 – 3), 171 – 189 (2005).

N. K. Myshkin and M. I. Petrokovets, Friction, Lubrication, Wear [in Russian], Fizmatgiz, Moscow (2007), 368 p.

V. N. Vinogradov, G. M. Sorokin, and M. G. Kolokol’nikov, Abrasive Wear [in Russian], Mashinostroenie, Moscow (1990), 224 p.

M. M. Khrushchev and M. A. Babichev, Abrasive Wear [in Russian], Nauka, Moscow (1970), 252 p.

V. V. Izmailov, A. F. Gusev, I. N. Nesterova, and A. A. Ivanova, “A method for determining rest friction coefficient of surface layers of a material, RF Patent No. 2150688,” Byull. Izobr. Polezn. Modeli, No. 16 (2000), publ. 10.06.2000.

I. S. Miroshnichenko, Hardening from Liquid State [in Russian], Metallurgiya, Moscow (1982), 168 p.

G. V. Lomaev and E. V. Kharanzhevskii, “Hardening treatment of a surface by the method of rapid laser recrystallization,” Metalloved. Term. Obrab. Met., No. 3, 27 – 32 (2002).

C. Navas, R. Colaco, J. De Damborenea, and R. Vilar, “Abrasive wear behavior of laser clad and flame sprayed-melted NiCrBSi coatings,” Surf. Coat. Technol., 200, 6854 – 6862 (2006).

M. Fernández, M. Cadenas, R. González, et al., “Wear behavior of laser clad NiCrBSi coating,” Wear, 259(7 – 12), 870 – 875 (2005).

R. González, M. Cadenas, M. Fernández, et al., “Wear behavior of flame sprayed NiCrBSi coatings remelted by flame or by laser,” Wear, 262(3 – 4), 301 – 307 (2007).

I. Hemmati, V. Ocelik, and J. T. M. De Hosson, “Effects of the alloy composition on phase constitution and properties of laser deposited Ni – Cr – B – Si coatings,” Phys. Proc., 41, 302 – 311 (2013).

Ch. Guo, J. Chen, J. Zhou, et al., “Effects of WC – Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating,” Surf. Coat. Technol., 206, 2064 – 2071 (2012).

J. M. Miguel, J. M. Guilemany, and S. Vizcaino, “Tribological study of NiCrBSi coating obtained by different processes,” Tribology Int., 36, 181 – 187 (2003).

The metallographic studies have been performed with the use of the equipment of the regional collective use center of the Tver State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 55 – 60, September, 2019.

Rights and permissions

About this article

Cite this article

Afanas’eva, L.E., Ratkevich, G.V. & Novoselova, M.V. Role of Structural Factor in Elevation of Wear Resistance of a Ni – Cr – B – Si Coating after Laser Treatment. Met Sci Heat Treat 61, 581–587 (2020). https://doi.org/10.1007/s11041-020-00465-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00465-9