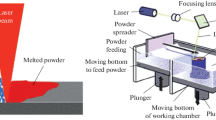

Main problems arising in installation of novel processes of production of permanent magnets based on the Fe – Cr – Co and Sm – Co systems are presented. The technological possibilities of production of permanent magnets from an alloy of the Fe – Cr – Co system by methods of MIM technology and powder metallurgy are described. Methods of MIM-technology with the use of domestic granulate are used to fabricate permanent magnets based on alloy 25Kh15KA (Fe – Co – Cr system) with residual induction Br = 1.12 T, maximum energy product (BH)max = 23.0 kJ/m3 and coercivity HcB = 39.7 kA/m.

Similar content being viewed by others

References

I. E. Graboy and T. Arndt, “Catamold® materials produced by the BASF Company for pressure casting of powders,” in: Proc. Seminar “Novel Materials and Articles from Metallic Powders. Technology. Production. Application” [in Russian], TPP-140, Yoshkar-Ola (2005), pp. 37 – 40.

M. I. Alymov, A. B. Ankudinov, V. A. Zelenskii, et al., “Effect of surface-active additions in milling on the processes of pressing, sintering and on magnetic properties of powder alloy FeCrCoMoW,” Perspekt. Mater., 4, 51 – 57 (2014).

Y. G. Dorofeev, B. G. Gasanov, and A. Y. Stopchenko, “Structuring and magnetic parameters in hot-forged Fe – Cr – Co powder alloys,” Powder Metall. Metal Ceram., 29(2), 121 – 124 (1990).

A. A. Shatsov, “Powder materials of the Fe – Cr – Co system” Metal Sci. Heat Treat., 46(3 – 4), 152 – 155 (2004).

A. S. Ustyukhin, M. I. Alymov, and I. A. Milyaev, “Magnetic hysteresis properties of Fe – 26Cr – 16Co hard magnetic powder alloys,” Pis’ma Mater., 4[1(13)], 59 – 61 (2014).

M. L. Green, R. C. Sherwood, and C. C. Wong, “Powder metallurgy processing of CrCoFe permanent magnet alloys containing 5 – 23 wt.% Co,” J. Appl. Phys., 53, 2398 – 2400 (1982).

I. M. Milyaev, M. I. Alymov, V. S. Yusupov, et al., “Effect of silicon and molybdenum on magnetic hysteresis properties of hard magnetic powder alloy 22Kh15KA,” Izv. Vyssh. Ucheb. Zaved., Poroshk. Metall. Funkts. Pokr., No. 4, 54 – 57 (2011).

A. V. Parkhomenko, A. P. Amosov, and A. R. Samboruk, “Science-intensive technology of injection powder molding of metallic articles (MIM technology),” Naukoemk. Tekhnol. Mahinostr., No. 12, 8 – 13 (2012).

A. S. Ustykhin, M. I. Alymov, and I. M. Milyeaev, “Magnetic hysteresis properties of Fe – 26Cr – 16Co hard magnetic powder materials,” Pis’ma Mater., 4[1(13)], 59 – 61 (2014).

V. S. Kraposhin, B. S. Vekshin, and E. G. Knizhnik, “Compaction of powder magnets based on SmCo5 by cold deformation,” Powder Metall., 11, 66 – 71 (1875).

S. Zhang, J. Tian, X. Qu, et al., “Antioxidation study of Sm(Co, Cu, Fe, Zr)z -sintered permanent magnets by metal injection molding,” J. Rare Earth, 24, 569 – 573 (2006).

J. Tian, S. Tao, X. Qu, et al., “2:17-type SmCo magnets prepared by powder injection molding using a water-based binder,” J. Magn. Magn. Mater., 320, 2168 – 2171 (2008).

J. Tian, S. Zhang, X. Qu, et al., “Behavior of residual carbon in Sm(Co, Cu, Fe, Zr)z permanent magnets,” J. Alloys Compd., 440, 89 – 93 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 34 – 37, September, 2019.

Rights and permissions

About this article

Cite this article

Baydarov, S.Y., Kamynin, A.V., Kraposhin, V.S. et al. Problems of Development of Mim Technology in Russia as Applied to Production of Permanent Magnets. Met Sci Heat Treat 61, 559–562 (2020). https://doi.org/10.1007/s11041-020-00461-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00461-z