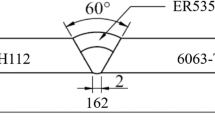

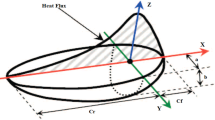

Welded joints of light structured sheets from aluminum alloy EN AW-6181-T4 (DIN EN 515) of the Al – Si – Mg system are studied. The welding is performed in an argon environment with a short arc by the method of cold metal transfer (CMT®). The results of the study are used in an amended Leblond model for describing the variation of the properties of the heat-affected zone of welded joints of structured sheets.

Similar content being viewed by others

References

R. Ossenbrink, V. Michailov, M. Tschuppe, and H. Hartmann, “Present and future situation of structured semi-finished products,” Stahl Eisen, 132(7), 65 – 71 (2012).

U. Butt, L. Jehring, and Ch. Egbers, “Mechanisms of drag reduction for circular cylinders with patterned surface,” Int. J. Heat Fluid Flow, 45, 128 – 134 (2014).

J. Bruckner, “Cold Metal Transfer — Ein neuer Prozess in der Fügetechnik,” DVS, 237, 32 – 37 (2005).

S.-F. Goecke, “EWM Mündersbach, Energiereduziertes Lichtbogen-Fügeverfahren für Wärmeempfindliche Werkstoffe,” DVS, 237, 44 – 48 (2005).

J. Kotowski, V. Michailov, and H. Wohlfahrt, “Calculation of microstructure evolution in 6082-T6 welds for residual stresses and distortion simulation,” in: Mathematical Modeling and Information Technologies in Welding and Related Processes, 16 – 20 Sept. 2002, Katsiveli, Crimea, Ukraine, pp. 87 – 91.

O. R. Myhr and Q. Grong, “Process modeling applied to 6082-T6 aluminum weldment. I. Reaction kinetics,” Acta Metall. Mater., 39(11), 2693 – 2702 (1991).

Q. Grong, Metallurgical Modeling of Welding, The Institute of Materials (1997).

J. B. Leblond and J. Devaux, “A new kinetic model for anisothermal metallurgical transformations in steel including effect of austenite grain size,” Acta Metall., 32, 137 – 146 (1984).

O. Dreibati, E. Ossenbrink, N. Doynov, and V. Michailov, “Physical and numerical simulation of thermo-mechanical properties in weld heat affected zone of an AlMgSi-alloy,” Mater. Sci. Forum, 706 – 709, 1491 – 1496 (2012).

The work has been performed at the Peter the Great St. Petersburg Polytechnic University in accordance with Agreement No. 14.Z50.31.0018 with the Ministry of Education and Science of the Russian Federation.

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 49 – 53, January, 2016.

Rights and permissions

About this article

Cite this article

Mikhailov, V.G. Prediction of the Properties of Heat-Affected Zone of Welded Joints of Sheets from Aluminum Alloys with Structured Surface. Met Sci Heat Treat 58, 46–50 (2016). https://doi.org/10.1007/s11041-016-9963-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-016-9963-1