Features of deformation regimes and mechanisms of microstructure formation in low-carbon steel 20 are studied using high-speed and multicycle hot plastic deformation methods in a Gleeble 3500 unit. Energy-force and temperature-speed regimes are established providing preparation of an ultrafine-grained structure with grain size of 150 – 1250 nm, similar to that achieved with higher degrees of cold plastic deformation. Specimen microhardness is determined.

Similar content being viewed by others

Notes

Studies were carried out in the Multiple-Access Center of the Nanosteels Research Institute of G. I. Nosov Magnitogorsk State Technical University. The authors thank M. P. Baryshnikov for help in performing tests in the Gleeble 3500 unit.

References

R. Song, J. G. Speer, D. K. Matlock, et al., “Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels,” Mater. Sci. Eng. A, 441(1 – 2), 1 – 17 (2006).

R. Z. Valiev and I. V. Aleksandrov, Bulk Nanostructured Metallic Materials [in Russian], IKTs Akademkniga, Moscow (2007).

A. I. Rudskoi, N. G. Kolbasnikov, O. G. Zotov, et al., “Study of the structure and properties of TRIP- steels in a Gleeble 3800 unit,” Chern. Met., No. 2, 8 – 14 (2010).

D. M. Chukin, A. S. Ishimov, and M. S. Zherebtsov, “Use of a Gleeble 3500 unit for analyzing phase transformations in steel of eutectoid composition microalloyed with boron,” in: M. V. Chukin (ed.), Treatment of Solid and Layered Materials [in Russian], Izd. Magnitogorsk Gos. Tekhn. Univ., Magnitogorsk (2012), Issue 38, pp. 52 – 57.

M. P. Baryshnikov, A. S. Ishimov, and M. S. Zherebtsov, “Modeling process with considerable degrees of deformation accumulation in a Gleeble 3500 research unit,” in: V. M. Kolokol’tsev (ed.), Actual Problems of Contemporary Science, Technology, and Education: Proc. 71st Inter-Regional Sci.-Tech. Conf. [in Russian], Izd. Magnitogorsk Gos. Tekhn. Univ., Magnitogorsk (2013), Vol. 1, pp. 251 – 254.

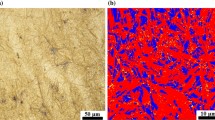

N. V. Koptseva, M. V. Chukin, and O. A. Nikitenko, “Use of Thixomet PRO software for qualitative analysis of ultrafinegrained structural low- and medium-carbon steels given equalchannel angular extrusion,” Metalloved. Term. Obrab. Met., No. 8, 12 – 17 (2012).

A. I. Meshkova, O. A. Nikitenko, Yu. Yu. Efimova, and N. V. Koptseva, “Quantitative analysis of the microstructure of billets of ultrafine-grained steel; grades 20 and 45 prepared by equal-channel angular extrusion,” Act. Probl. Sovremen. Nauki, Tekh. Obraz., No. 1, 153 – 156 (2011).

N. V. Koptseva, Yu. Yu. Efimova, M. P. Baryshnikov, and O. A. Nikitenko, “Structure formation and mechanical properties of carbon structural steels during nanostructuring by equalchannel angular extrusion,” Deform. Razrush. Materialov, No. 7, 11 – 17 (2011).

N. V. Koptseva, “Deformation refinement of the structure of carbon structural steels by equal-channel angular extrusion in order to improve manufactured item strength,” Stal’, No. 8, 50 – 56 (2012).

V. I. Zel’dovich, N. Yu. Frolova, A. É. Khaifets, et al., “Improvement of titanium mechanical properties by dynamic channel angular extrusion,” Vopr. Materialved., No. 1(69), 29 – 37 (2012).

The work was carried out with financial support of the Russian Ministry of Education within the scope of implementing a combined project for creation of hi-tech production with participation of higher education establishments (agreement No. 02.G25.31.0178), base (No. 2014_80, 2014-06 GZ) and the planned part of state assignment (No. 11.1525.2014K of July 18, 2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 10 – 13, June, 2016

Rights and permissions

About this article

Cite this article

Koptseva, N.V., Nikitenko, O.A. & Efimova, Y.Y. Study of Microstructure Formation of Carbon Steel Under High-Speed and Multicycle Hot Plastic Compressive Deformation Using A Gleeble 3500 Unit. Met Sci Heat Treat 58, 318–323 (2016). https://doi.org/10.1007/s11041-016-0010-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-016-0010-z