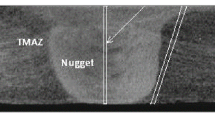

Some special features of abnormal grain growth in welded joints of aluminum alloys formed by fiction stir welding (FSW) are studied. The microstructure and the texture of the alloys are determined after welding and annealing at 400, 450 and 500°C for different times. The abnormal grain growth is shown to depend much on the macroscopic inhomogeneity of the structure inside the weld.

Similar content being viewed by others

Notes

We present the international names of the alloys because we have studied metals of foreign producers.

It should be noted that the studied alloy also contained dispersoids of phase Al3Cr2Mg3. Since the volume fraction of this phase was very low, its action of the growth of grains was presumed to be low and was not allowed for in the simulation.

References

R. S. Mishra and Z. Y. Ma, “Friction stir welding and processing,” Mater. Sci. Eng. R, 50, 1 – 78 (2005).

Kh. A. A. Hassan, A. F. Norman, D. A. Price, and P. B. Prangnell, “Stability of nugget zone grain structures in high strength Al alloy friction stir welds during solution treatment,” Acta Mater., 51, 1923 – 1936 (2003).

M. Karlsen, Q. Frigaard, J. Hielen, Q. Grong, and H. Norum, “SEM-EBSD characterization of the deformation microstructure in friction stir welded 2024 T351 aluminum alloy,” Mater. Sci. Forum, 426 – 432, 2861 – 2866 (2003).

I. Charit and R. S. Mishra, “Evaluation of microstructure and superplasticity in friction stir processed 5083 Al alloy,” J. Mater. Res., 19, 3329 – 3342 (2004).

S. Mironov, Y. Motohashi, and R. Kaibyshev, “Grain growth behaviors in friction-stir-welded ZK60 magnesium alloy,” Mater. Trans., 48(6), 1387 – 1395 (2007).

L. Charit and R. S. Mishra, “Abnormal grain growth in friction stir processed alloys,” Scr. Mater., 58, 367 – 371 (2008).

M. M. Attallah and H. G. Salem, “Friction stir welding parameters: a tool for controlling abnormal grain growth during subsequent heat treatment,” Mater. Sci. Eng. A, 391, 51 – 59 (2005).

K. Chen, W. Gan, K. Okamoto, K. Chung, and R. H. Wagoner, “The mechanism of grain coarsening in friction-stir-welded AA5083 after heat treatment,” Metall. Mater. Trans. A, 42, 488 – 507 (2011).

M. A. Safarkhanian, M. Goodarzi, and S. M. A. Boutorabi, “Effect of abnormal grain growth on tensile strength of Al – Cu – Mg alloy friction stir welded joints,” J. Mater. Sci., 44(20), 5452 – 5458 (2009).

Y. S. Sato, H. Watanabe, and H. Kokawa, “Grain growth phenomena in friction stir welded 1100 Al during post-weld heat treatment,” Sci. Tech. Weld. Join., 12(4), 318 – 323 (2007).

S. Mironov, K. Masaki, Y. S. Sato, and H. Kokawa, “Relationship between material flow and abnormal grain growth in friction-stir welds,” Scr. Mater., 67, 983 – 986 (2012).

S. Mironov, K. Masaki, Y. S. Sato, and H. Kokawa, “Texture produced by abnormal grain growth in friction stir-welded aluminum alloy 1050,” Metall. Mat. Trans. A, 44, 1153 – 1157 (2013).

U. F. H. R. Suhuddin, S. Mironov, Y. S. Sato, H. Kokawa, and C.-W. Lee, “Grain structure evolution during friction stir welding of AZ31 magnesium alloy,” Acta Mater., 57, 5406 – 5418 (2009).

F. J. Humphreys, “A unified theory of recovery, recrystallization and grain growth of cellular microstructures. I. The basic model,” Acta Mater., 45(10), 4231 – 4240 (1997).

F. J. Humphreys, “A unified theory of recovery, recrystallization and grain growth of cellular microstructures. II. The effect of second-phase particles,” Acta Mater., 45(12), 5031 – 5039 (1997).

R. W. Fonda and K. E. Knipling, “Texture development in friction stir welds,” Sci. Tech. Weld. Join., 16(4), 288 – 194 (2001).

A. P. Reynolds, E. Hood, and W. Tang, “Texture in friction stir welds of Timetal 21S,” Scr. Mater., 52, 491 – 494 (2005).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Phenomena, Elsevier, Oxford (2004), 574 p.

The author is thankful to Professors Y. S. Sato, H. Kokawa and A. V. Korznikov for the discussion of the results obtained and scientific consultations, to Doctors K. Masaki and A. Honda for the help with the experiments, and to T. N. Kon’kova for the help with preparation of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 38 – 46, January, 2015.

Rights and permissions

About this article

Cite this article

Mironov, S.Y. About Abnormal Grain Growth in Joints Obtained by Friction Stir Welding. Met Sci Heat Treat 57, 40–47 (2015). https://doi.org/10.1007/s11041-015-9832-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-015-9832-3