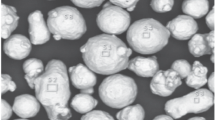

Results are provided for a study of microstructure and microhardness of a layer of powder steel–copper pseudo alloy after laser heat treatment with a 1 kW power fiber laser.

Similar content being viewed by others

References

A. A. Shatsov, “Optimization of composition and heat treatment regime for steel–copper composite material,” Izv. Vyssh. Uchebn. Zaved, Tsvetn. Met., No. 5, 52 – 56 (1998).

Yu. I. Lopukhov and Sh. S. Shakarimov, “Thermal strengthening of the surfaces of iron-carbon alloys by laser radiation,” Vestn. VKGTU, Nauka o Zemle, No. 3, 10 – 17 (2011).

N. K. Tolochko, “Use of lasers in powder metallurgy,” Fiz. Khim. Obrab. Mater., No. 1, 94 – 98 (1995).

V. S. Postnikov, V. S. Tomsinskii, and Yu. V. Palkina, “Laser hardening of powder steel ZhGr0.5D3L0.3,” Metalloved. Term. Obrab. Met., No. 11, 32 – 34 (1991).

V. N. Antsiferov, A. M. Shmakov, and S. V. Shtennikov, “Features of structure formation and properties of powder carbon steels with laser thermal modification. Communication 1. Structure of modified steels,” Poroshk. Metall., No. 7, 76 – 79 (1992).

A. V. Marants, Zh. A. Sentyurina, I. A. Yadroitseva, et al., “Laser treatment of sintered powder steel SPM14A7M5,” Izv. Vyssh. Uchebn. Zaved, Poroshk. Metall. Funkts. Pokrytiya, No. 2, 19 – 25 (2013).

A. N. Safonov, “Structure and microhardness of surface layers of iron-carbon alloys after laser hardening,” Metalloved. Term. Obrab. Met., No. 2, 20 – 24 (1996).

S. A. Astapchik, V. B. Babushkin, and V. S. Ivashko, “Structure and phase transformations in steels and alloys with laser heat treatment,” Metalloved. Term. Obrab. Met., No. 2, 2 – 5 (1991).

N. A. Smirnova and A. I. Misyurov, “Features of structure formation with laser treatment,” Vestn. MGTU im N. É. Baumana, Ser. Mashinostroenie, No. 6(6), 115 – 129 (2012).

G. A. Turichin, E. V. Zemlyakov, and E. U. Pozdeeva, “Production possibilities of laser facing using powerful fiber lasers,” Metalloved. Term. Obrab. Met., No. 3, 35 – 40 (2012).

O. G. Levoino, M. A. Kardapolova, and A. S. Chaus, “Increase in wear resistance of sprayed coatings of bronze BRA7N6F by laser alloying,” Metalloved. Term. Obrab. Met., No. 3, 40 – 45 (2012).

V. V. Lisenkov, V. V. Osipov, and V. V Platonov, “Reaction of powerful fiber ytterbium laser radiation with dielectric inhomogeneous targets,” Zh. Tekhn. Fiz., 83(10), 78 – 84 (2013).

V. O. Popov, “Laser hardening of steels: comparison of fiber and CO2 lasers,” Photonika, No. 4, 18 – 21 (2009).

V. S. Kraposhin, “Effect of residual austenite on steel and cast iron properties after surface fusion,” Metalloved. Term. Obrab. Met., No. 2, 2 – 5 (1994).

V. S. Kraposhin, K. V. Shalevich, and T. M. Vyaz’mina, “Effect of laser heating on amount of residual austenite in steel and cast iron,” Metalloved. Term. Obrab. Met., No. 10, 21 – 29 (1989).

V. G. Gilev, E. A. Morozov, A. S. Denisova, and A. M. Khanov, “Study of microstructure and surface relief of laser heat treatment of thin-walled cylinder made of powder steel – copper pseudo-alloy,” Izv. Samar. Nauch. Tsentra Ross. Akad. Nauk, 14[4(5)], 1212 – 1217 (2012).

Yu. F. Ivanov, S. Yu. Filimonov, A. D. Teresov, et al., “Alloying the surface of carbon steel with copper by electric explosion of wire and subsequent electron beam treatment,” Izv. Tomsk. Politekh. Univ., 318(2), 101 – 105 (2011).

F. Goia and M. de Lima, “Surface hardening of an AISI D6 cold work steel using a fiber laser,” J. ASTM Int., 8(2), 315 – 318 (2011).

GOST R ISO 1146-1–2008. Lasers and laser units (systems). Methods for measuring width, divergence angles, and laser beam propagation coefficients [in Russian].

A. G. Grogor’yants and V. V. Vasil’tsov, “Spatial structure of powerful waveguide and fiber lasers for technology,” Vestn. MGTU im N. É. Baumana, Ser. Mashinostroenie, No. 6, 5 – 33 (2012).

F. Qiu and V. Kujanpää, “Transformation hardening of medium-carbon steel with a fiber laser: the influence of laser power and laser power density,” Mechanika (Mechanics), 17(3), 318 – 323 (2011).

Purushothaman Dinesh Babu, Gengusamynaidu Buvanashekaran, and Karupuudaiyar R. Balasubramanian, “Experimental studies on the microstructure and hardness of laser transformation hardening of low alloy steel,” Trans. Canadian Soc. Mech. Eng., 36(3), 241 – 257 (2012).

V. S. Kraposhin and I. F. Kraposhina, “Effect of laser radiation parameters on size of steel 45 irradiated zones,” Fiz. Khim. Obrab. Mater., No. 6, 19 – 24 (189).

R. K. Shiue and C. Chen, “Laser transformation hardening of tempered 4340 steel,” Metall. Trans. A, 23A, 163 – 170 (1992).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 34 – 40, May, 2014.

Rights and permissions

About this article

Cite this article

Gilev, V.G., Bezmaternykh, N.V. & Morozov, E.A. Study of Steel–Copper Pseudo Alloy Microstructure and Microhardness After Laser Heat Treatment. Met Sci Heat Treat 56, 262–268 (2014). https://doi.org/10.1007/s11041-014-9743-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-014-9743-8