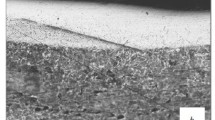

Structural changes developing in surface layers of plates from steel 20 in the process of explosive welding are studied with the help of light metallography and scanning and transmission electron microscopy. Mathematical simulation is used to compute the depth of the action of severe plastic deformation due to explosive welding of steel plates on the structure of their surface layers.

Similar content being viewed by others

References

A. A. Deribas, The Physics of Hardening and ExplosiveWelding [in Russian], Nauka, Moscow (1972), 188 p.

I. D. Zakharenko, Explosive Welding of Metals [in Russian], Navuka i Tekhnika, Minsk (1990), 205 p.

I. A. Bataev, A. A. Bataev, V. I. Mali, et al., “Peculiarities of weld seams and adjacent zones structures formed in process of explosive welding of sheet steel plates,” Mater. Sci. Forum, 673, 95 – 100 (2011).

I. A. Bataev, A. A. Bataev, V. I. Mali, et al., “Structure and fatigue crack resistance of multilayer materials produced by explosive welding,” Adv. Mater. Res., 287 – 290, 108 – 111 (2011).

I. A. Balaganskii, I. A. Bataev, T. V. Zhuravina, et al., “Structure and mechanical properties of multilayer composite materials from titanium VT1-0,” Obrab. Met. Tekhnol. Oborud. Instr., No. 2, 43 – 45 (2011).

A. A. Berdychenko, L. B. Pervukhin, and O. L. Pervukhina, “Evolution of titanium structure in the zone of a joint obtained by explosive welding,” Metalloved. Term. Obrab. Met., No. 10, 19 – 24 (2009).

S. V. Gladkovskii, T. A. Trunina, E. A. Kokovikhin, et al., “Structure and properties of a composite from steels 12Kh18N10T and 20 obtained by explosive welding,” Metalloved. Term. Obrab. Met., No. 9, 34 – 39 (2009).

V. A. Chuvilov, S. V. Kuz’min, V. I. Lysak, and A. V. Borshchov, “A study of the structure and properties of three-layer copper-steel and copper-aluminum composites obtained by a battery scheme by explosive welding,” Perspekt. Mater., No. 1, 91 – 97 (2010).

V. V. Rybin, B. A. Grinberg, O. V. Antonova, et al., “Formation of vortexes in explosive welding (titanium – orthorhombic titanium aluminide),” Fiz. Met. Metalloved., 108(4), 371 – 384 (2009).

I. A. Bataev, A. A. Bataev, I. A. Balaganskii, et al., “Localization of plastic flow in low-carbon steel deformed by explosion,” Fiz. Mesomekhan., 14(1), 93 – 99 (2011).

I. A. Bataev, I. A. Balagansky, A. A. Bataev, and Kazuyaki Hokamoto, “Transformation of structure in carbon steel specimen under loading by mach stem, formed in preliminary compressed high explosive charge TG-40,” Mater. Sci. Forum, 673, 89 – 94 (2011).

The work has been performed with financial support of the Russian Foundation for Basic Research (Project 12-02-31707mol_a).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 54 – 59, September, 2013.

Rights and permissions

About this article

Cite this article

Bataev, I.A., Bataev, A.A., Mali, V.I. et al. Structural Changes of Surface Layers of Steel Plates in the Process of Explosive Welding. Met Sci Heat Treat 55, 509–513 (2014). https://doi.org/10.1007/s11041-014-9663-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-014-9663-7