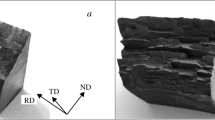

The effect of controlled rolling deformation regimes on features of hot-deformed austenite structure formation and the final microstructure of low-carbon microalloyed pipe steel is studied. The effect of method for performing the rolling finish stage of grain size and austenite size distribution is established. The effect of deformation level and temperature of the finish rolling stage on final steel microstructure is studied.

Similar content being viewed by others

References

F. B. Pickering, Physical Metallurgy and Development of Steels [Russian translation], Metallurgiya, Moscow (1982).

I. Tamura, “Some fundamental steps in thermomechanical processing of steels,” Trans. ISIJ, 27, 763–780 (1987).

K. B. Panigrahi, “Processing of low carbon steel plate and hot strip-an overview,” Bull. Mater. Sci., 24, No. 4, 361–371 (2001).

L. I. Éfron, Yu. D. Morozov, and E. A. Goli-Oglu, “Study of the effect of cold rolling temperature-deformation regimes on lowalloy steel microstructure and mechanical properties for large diameter gas and oil pipelines,” Metallurg, No. 1, 69–74 (2011).

A. Abdollah-Zedeh and D. P. Dunne, “Effect of Nb on recrystallization after hot deformation in austenitic Fe – Ni steels,” ISIJ Int., 43, 1213–1218 (2003).

D. Sun, S. Torizuka, A. Ohmor, and T. Inoue, “Dynamic restoration process of Ni – 30Fe alloy during hot deformation,” ISIJ Int., 42, 432–439 (2002).

E. Gudremont, Special Steels [Russian translation], Metallurgiya, Moscow (1966).

“Modelling thermomechanical rolling — way for reducing expenditure in creating new production,” Metallurg, No. 1, 3 (2010).

T. Tanaka, “Science and technology of hot rolling process of steel,” in: Microalloying’95 Conf. Proc. (1995).

T. Siwecki, “Modeling of microstructure evolution during recrystallization controlled rolling,” ISIJ Int., 32, 368–376 (1992).

S. Medina and A. Quispe, “Improved model for static recrystallization kinetics of hot deformed austenite in low alloy and Nb/V microalloyed steels,” ISIJ Int., 41, 774–781 (2001).

S. Yu. Nastich, Yu. D. Morozov, M. Yu. Matrosov, et al., “Assimilation of production in 5000 OAO MMK mill for thick rolled product of low-alloy steels with improved strength and cold resistance,” Metallurg, No. 11, 57–64 (2011).

Yu. D. Morozov, E. A. Goli-Oglu, S. Yu. Nastich, et al., “Development of TMT regimes for low-carbon microalloyed steel under 5000 OAO MMK mill conditions providing high cold resistance for thick rolled product,” Stal’, No. 2, 81–85 (2012).

S. S. Gorelik, Recrystallization of Metals and Alloys [in Russian], Metallurgiya, Moscow (1978).

D.-W. Sun, S. Torizuka, A. Ohmori, et al., “Dynamic restoration process of Ni – 30Fe alloy during hot deformation,” ISIJ Int., 42, 432–439 (2002).

G, V. Kurdyumov, L. M. Utevskii, and R. I. Éntin, Transformation in Iron and Steel [in Russian], Nauka, Moscow (1977).

C. Ouchi, T. Sampei, and I. Kozasu, “The effect of hot rolling condition and chemical composition on the onset temperature of γ→α transformation after hot rolling,” Trans. ISIJ., 22, 214–222 (1982).

J. Liu and J. Yagimoto, “Ferrite nucleation kinetics inside austenite grain,” ISIJ Int., 47(8), 1188–1194 (2007).

S. Yu. Nastich, “Effect of bainite component morphology for low-carbon steel X70 microstructure on plate cold brittleness,” Metallurg, No. 3, 62–69 (2012).

L. I. Éfron, Yu. D. Morozov, and E. A. Goli-Oglu, “Effect of cold rolling regime of change in structure and set of mechanical properties of low-carbon microalloyed steels,” Stal’, No. 5, 67–72 (2011).

F. Boratto, R. Borbasa, S. Yue, and J. J. Jonas, “Thermomechanical processing of steels and other materials,” in: Thermec-88, Tokyo, Japan (1988), pp. 383–390.

F. Fletcher, in: Austenite Processing Symposium, Paris, France (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 9 – 13, June, 2013.

Rights and permissions

About this article

Cite this article

Goli-Oglu, E.A., Éfron, L.I. & Morozov, Y.D. Effect of deformation regime in main stages of controlled rolling on pipe steel microstructure. Met Sci Heat Treat 55, 294–297 (2013). https://doi.org/10.1007/s11041-013-9622-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9622-8