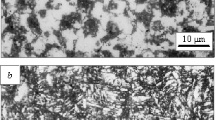

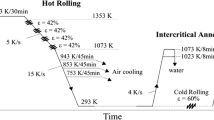

The optimum parameters for the continuous annealing of cold-rolled dual-phase steel are determined by the method of orthogonal design to obtain an ultimate rupture strength exceeding 1000 MPa and an elongation exceeding 12%. The microstructure of the steel is studied with the help of optical and transmission electron microscopy.

Similar content being viewed by others

References

A. P. Modi, “Effects of microstructure and experimental parameters on high stress abrasive wear behaviour of a 0.19 wt.% C dual phase steel,” Tribol. Int., 40, 490–497 (2007).

Q. Meng, J. Li, J. Wang, et al., “Effect of water quenching process on microstructure and tensile properties of low alloy cold rolled dual-phase steel,” Mater. Design., 30, 2379–2385 (2009).

J. Luo, W. Shi, Q. H. Huang, and L. Li, “Heat treatment of cold-rolled low-carbon Si – Mn dual phase steels,” J. Iron Steel Res. Int., 17, 54–58 (2010).

X. Liang, J. Li, and Y. Peng, “Effect of water quench process on mechanical properties of cold rolled dual phase steel microalloyed with niobium,” Mater. Lett., 62, 327–329 (2008).

S.-J. Kim, Y.-G. Cho, C.-S. Oh, et al., “Development of a dual phase steel using orthogonal design method,” Mater. Design., 30, 1251–1257 (2009).

S. Sun and M. Pugh, “Properties of the themomechanically processed dual-phase steels containing fibrous martensite,” Mater. Sci. Eng. A, 35, 298–308 (2002).

Y. Q. Cheng, H. L. Chen, L. Y. Fan, et al., “On-line conversion and determination of artemisinin and its kinetic parameters using orthogonal design by coupling of flow injection with capillary electrophoresis,” Anal. Chim. Acta, 525, 239–245 (2004).

S. Kuang, Y. Kang, H. Yu, and R. Liu, “Effect of continuous annealing parameters on the mechanical properties and microstructures of a cold rolled dual phase steel,” Int. J. Min. Met. Mater., 16, 159–164 (2009).

C. Ghosh, A. Haldar, P. hosh, and R. K. Ray, “Microstructure, texture, grain boundary characteristics and mechanical properties of a cold rolled and annealed ferrite-bainite dual phase steel,” Int. J. Mater. Res., 101, 1252–1263 (2010).

G. S. Huppi, D. K. Matlock, and G. Krauss, “An evaluation of the importance of epitaxial ferrite in dual-phase steel microstructures,” Scr. Metall., 14, 1239–1243 (1980).

S. G. Chowdhury, E. V. Pereloma, and D. B. Santos, “Evolution of texture at the initial stages of continuous annealing of cold rolled dual-phase steel: effect of heating rate,” Mater. Sci. Eng. A, 480, 540–548 (2008).

M. Erdogan and S. Tekeli, “The effect of martensite particle size on tensile fracture of surface-carburised AISI 8620 steel with dual phase core microstructure,” Mater. Design., 23, 597–604 (2002).

J. Rudnizki, B. Böttger, U. Prahl, and W. Bleck, “Phase-field modeling of austenite formation from a ferrite plus pearlite microstructure during annealing of cold-rolled dual-phase steel,” Metall. Mater. Trans. A, 42, 2516–2525 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 43 – 48, May, 2013.

Rights and permissions

About this article

Cite this article

Dai, Q., Song, R. & Guo, Z. Choosing the optimum heat treatment for cold-rolled dual-phase steel by the method of orthogonal design. Met Sci Heat Treat 55, 270–274 (2013). https://doi.org/10.1007/s11041-013-9618-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9618-4