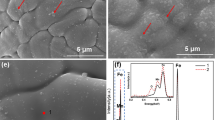

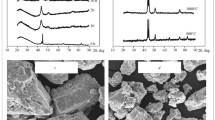

The microstructure and impact strength of powder steels containing 0 – 2 wt.% Ni and 0.3 wt.% graphite is studied after quenching from the intercritical region (from 730 to 760°C) and tempering.

Similar content being viewed by others

References

B. A. Gething, D. F. Heaney, D. A. Koss, and T. J. Mueller, “The effect of nickel on the mechanical behavior of molybdenum P_M steels,” Mater. Sci. Eng. A, 390, 19 – 26 (2005).

N. Chawla, T. F. Murphy, K. S. Narasimhan, et al. “Axial fatigue behavior of binder-treated versus diffusion alloyed powder metallurgy steels,” Mater. Sci. Eng. A, 308, 180 – 188 (2001).

W. F.Wang, “Effect of alloying elements and processing factors on the microstructure and hardness of sintered and inductionhardened Fe – C – Cu alloys,” Mater. Sci. Eng. A, 402, 92 – 97 (2005).

H. Chen, Y. Y. Li, Y. B. Liu, and X. J. Cao, “Influence of chromium on microstructure and sintering properties of FeNiMoCu system prealloyed powders,” J. Mater. Proc. Tech., 182, 462 – 468 (2007).

H. D. Armas, L. Llanes, J. Peñafiel, et al., “Tempering effects on the tensile response and fatigue life behavior of a sinter-hardened steel,” Mater. Sci. Eng. A, 277, 291 – 296 (2000).

P. D. Bilmes, M. Solari, and C. L. Llorente, “Characteristics and effects of austenite resulting from tempering of 13Cr – NiMo martensitic steel weld metals,” Mater. Charact., 46, 285 – 296 (2001).

G. Fillari, T. Murphy, and I. Gabrielov, “The hard facts of carbon and casings,” Metal Powder Rep., 60, 32 – 41 (200).

K. S. Narasimhan, “Sintering of powder mixtures and the growth of ferrous powder metallurgy,” Mater. Chem. Phys., 67, 56 – 65 (2001).

H. Zhang and G. M. German, “Homogeneity and properties of injection moulded Fe – Ni alloys,” Metal Powder Rep., 56, 18 – 22 (2001).

H. Terao, “Structure and mechanical properties of high-manganese dual-phase steels,” J. Mater. Sci., 21, 1715 – 1720 (1986).

S. S. M. Tavares, P. D. Pedroza, J. R. Teodósio, and T. Gurova, “Mechanical properties of a quenched and tempered dual phase steel,” Scr. Mater., 40, 887 – 892 (1999).

Y. S. Ahn, H. D. Kim, T. S. Byun, et al., “Application of intercritical heat treatment to improve toughness of SA508 Cl.3 reactor pressure vessel steel,” Nucl. Eng. Des., 194, 161 – 177 (1999).

S. Tekeli and A. Güral, “Microstructural characterization and impact toughness of intercritically annealed PM steels,” Mater. Sci. Eng. A, 406, 172 – 179 (2005).

R. L. Klueh, P. J. Maziasz, and E. H. Lee, “Manganese as an austenite stabilizer in Fe – Cr – Mn – C steels,” Mater. Sci. Eng. A, 102, 115 – 124 (1998).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 26 – 30, May, 2013.

Rights and permissions

About this article

Cite this article

Güral, A. Effect of Heat Treatment on Impact Strength of Powder Steels with 0 – 2%Nickel. Met Sci Heat Treat 55, 252–256 (2013). https://doi.org/10.1007/s11041-013-9615-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9615-7