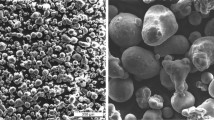

Mechanisms of structure formation in hypereutectic alloys of the Al – Si system during micro-laser facing are studied. Grain size composition, surface morphology, microstructure, and phase composition of starting powder of different chemical composition are determined. The effect of facing parameters on facing bead structure and geometrical properties is studied. The fundamental technological possibility of using micro-laser facing in order to obtain high-precision component structural elements made of aluminum alloys with lateral resolution of about 100 μm is studied. Recommendations are made for micro-laser facing of hypereutectic alloys of the Al – Si system with an indication of optimum treatment regimes and starting powder chemical composition.

Similar content being viewed by others

Notes

Experiments for laser facing were performed in the Fraunhofer IWS Institute, Dresden, Germany.

References

A. Streek, M. Müller, T. Süß, et al., “Lasermikrosintern-Stand und Perspektiven,” in: 20th International Scientific Conference Mittweida. October 28 – 29, 2009, Sci. Reports, No. 4, 37 – 43 (2009).

S. N. Grigor’ev, “Solution of the problem of re-equipping engineering,” ITO (Tool – Technology – Equipment), No. 10, 14 – 19 (2008).

S. Nowotny, Oberflächenbeschichten und formgebendes Auftragschweißen mit laserbasierten hybriden Fertigungsverfahren, Fraunhofer IRB Verlag (2004).

G. O. Gvozdeva, T. V. Tarasova, and S. Nowotny, “Auftragschweißen von Aluminium-Legierungen,” in: Materialen zum internationalen wissenschaftlichen, Seminar der DAAD-Stipendiaten “Michail Lomonossov” und “Immanuel Kant” in Moskau (2012), pp. 27 – 31

T. V. Tarasova, “Prospects for using laser radiation for improving corrosion-resistant steel wear resistance,” Metalloved. Term. Obrab. Met., No. 6, 54 – 58 (2010).

T. V. Tarasova and G. O. Gvozdeva, “Study of aluminum alloy surface laser alloying,” Nauka Obrazov.: Élektr. Nauch.-Tekhn. Izd., No. 3, 48 (2012).

I. Yu. Smurov, I. A. Movchan, I. A. Yadroitsev, et al., “Additive production by means of laser,” Vestn. MGTU Stankin, 2(4), 144 – 146 (2011).

T. V. Tarasova, G. O. Gvozdeva, and E. P. Tikhonova, “Prospects for using laser radiation for nonferrous alloy surface treatment,” Vestn. MGTU Stankin, No. 2, 140 – 143 (2012).

G. O. Gvozdeva, K. O. Bazaleeva, Yu. A. Puchkov, and T. V. Tarasova, “Physicochemical properties of multilayer Ti/Al nanostructured coating,” Vse Materialy. Éntsikloped. Sprav., No. 1, 13 – 19 (2011).

E. N. Kablov, V. S. Ryl’nikov, A. G. Evgenov, and A. N. Afanas’ev-Khodykin, “Study of finely dispersed solder powders for diffusion vacuum soldering, prepared by melt atomization,” Vestn. MGTU im N. É. Baumana, No. SP2, 79 – 97 (2011).

T. V. Tarasova and G. O. Gvozdeva, “Structure formation in hypereutectic alloys of the Al – Si system with surface laser treatment,” Uprochn. Tekhn. Pokryt., No. 12, 35 – 40 (2012).

Aluminum Alloys. Industrially Deformed, Sintered and Cast Aluminum Alloys. Handbook [in Russian], Metallurgiya, Moscow (1972).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 16 – 21, May, 2013.

Rights and permissions

About this article

Cite this article

Grigor’ev, S.N., Tarasova, T.V., Gvozdeva, G.O. et al. Micro-Laser Facing of Al – Si System Alloys. Met Sci Heat Treat 55, 242–246 (2013). https://doi.org/10.1007/s11041-013-9613-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9613-9