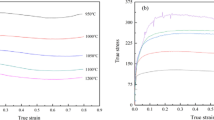

Aluminum alloy 3003 is studied after isothermal compression in a Gleeble-1500 machine at a rate of 0.01 − 10 sec − 1 in the temperature range of 300 − 500°C. The curves plotted in the coordinates “strain hardening rate − strain” are used to determine the critical strain εc and the static strain εs for dynamic recrystallization, and the curve of the dynamic recrystallization is plotted. A mathematical model describing the kinetics of the dynamic recrystallization as a function of the treatment parameters is suggested.

Similar content being viewed by others

References

J. J. Jonas, “Dynamic recrystallization − scientific curiosity or industrial tool,” Mater. Sci. Eng., AA184, 155–165 (1994).

E. I. Poliak and J. J. Jonas, “A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization,” Acta Mater., 44, 127–136 (1996).

G. R. Stewart, J. J. Jonas, and F. Montheillet, “Kinetics and critical conditions for the initiation of dynamic recrystallization in 304 stainless steel,” ISIJ Int. 44(9), 1581–1589 (2004).

S. H. Cho, S. I. Kim, and Y. C. Yoo, “Determination of “no-crystallization” temperature of invar alloy by fractional softening measurement during the multistage deformation,” J. Mater. Sci. Lett., 16, 1836–1837 (1997).

K. P. Rao, Y. K. D. V. Prasad, and E. B. Hawbolt, “Hot deformation studies on a low-carbon steel, Part 1. Flow curves and the constitutive relationship,” Mater. Proc. Technol., 56, 897–907 (1996).

S. F. Medina and C. A. Hernandez, “Modeling of the dynamic recrystallization of austenite in low alloy and microalloyed steels,” Acta Mater., 44, 165–171 (1996).

E. I. Poliak and J. J. Jonas, “Initiation of dynamic recrystallization in constant strain rate hot deformation,” ISIJ Int., 43(5), 684–691 (2003).

K. Karhausen and R. Kopp, “Model for integrated process and microstructure simulation in hot forming,” Steel Res., 63, 247–256 (1992).

S. F. Medina and C. A. Fernandez, “General expression of the Zener − Hollomon parameter as a function of the chemical composition of low alloy and microalloyed steels,” Acta Mater., 44, 137–148 (1996).

G. S. Fu, W. Z. Chen, and K. W. Qian, “Synthetical technique of high-efficient melt-treatment of aluminum and its effect,” Chinese J. Nonferrous Metals, 12(2), 269–274 (2002).

J. J. Jonas and E. I. Poliak, “The critical strain for dynamic recrystallization in rolling mills,” Mater. Sci. Forum, 426–432, 57–66 (2003).

E. I. Poliak and J. J. Jonas, “Critical strain for dynamic recrystallization in variable strain rate hot deformation,” ISIJ Int., 43, 692–700 (2003).

G. R. Stewart, A. M. Elwazri, S. Yue, and J. J. Jonas, “Modeling of dynamic recrystallization kinetics in austenitic stainless and hypereutectoid steels,” Mater. Sci. Technol., 22(5), 519–524 (2006).

L. F. Dong, Y. X. Zhong, Q. X. Ma, and C. L. Yuan, “Research on the dynamic recrystallization behavior of 20SiMn,” China Mech. Eng., 19(10), 1245–1249 (2008).

J. H. Beynon and C. M. Sellars, “Modeling microstructure and its effects during multi-pass hot rolling,” ISIJ Int., 32(3), 359–367 (1992).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 51–56, April, 2013.

Rights and permissions

About this article

Cite this article

Chen, G., Fu, G., Yan, W. et al. Mathematical Model of Dynamic Recrystallization of Aluminum Alloy 3003. Met Sci Heat Treat 55, 220–225 (2013). https://doi.org/10.1007/s11041-013-9609-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9609-5