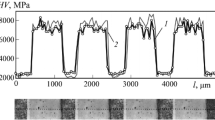

The possibilities of certification of hardened surface layers by measurement of coercive force, eddy current inspection and analysis of the field dependence of differential magnetic permeability μ d (H) are considered. The advantages of analysis of the pattern of peaks on the μ d (H) dependence for estimating the state of surface-hardened steels subjected to subsequent force loading are shown.

Similar content being viewed by others

References

B. A. Proskuryakov, Technological Reference Dictionary on Surface Engineering [in Russian], Mashinostroenie, Moscow (2006), 368 p.

T. Bell, “Fundamentals of surface engineering,” Mater. Eng., 1(1), 37–52 (1989).

N. N. Mikheev, “A magnetic method for controlling the thickness of quenched, carburized, nitrided and decarburized layers on steel parts,” Izv. Akad. Nauk SSSR (OTN), Nos. 5 – 6, 53–68 (1943).

M. N. Mikheev, “Magnetic properties of carburized and nitrided steels,” Zh. Teor. Fiz., 15(9), 677–680 (1945).

M. N. Mikheev, P. I. Zimnev, and K. E. Miloslavskii, “Control of the depth of carburization and quality of heat treatment with the help of a coercive force meter,” Vestn. Mashinostr., Nos. 6 – 7, 70 (1945).

V. V. Klyuev (ed.), Devices for Nondestructive Inspection of Materials and Articles. A Handbook [in Russian], Mashinostroenie, Moscow (1986), Book 2, 488 p.

V. E. Shcherbakov and E. S. Gorkunov, Magnetic Control of the Quality of Metals [in Russian], UrO RAN, Ekaterinburg (1996), 264 p.

G. V. Bida, “Magnetic control of the depth and hardness of surface-hardened layers on articles,” Defektoskopiya, No. 5, 10–28 (2006).

G. V. Bida and A. P. Nichiporuk, “Coercive force measurement in nondestructive checking,” Defektoskopiya, No. 10, 3–28 (2000).

M. N. Mikheev, G. V. Bida, V. N. Kostin, et al., “Checking the depth and hardness of HFC-hardened layers on automotive crankshaft necks,” Defektoskopiya, No. 8, 12–17 (1985).

I. M. Shif and B. M. Neizvestnov, “Magnetic control of hardening of the surface plastically deformed layer of steel parts,” Defektoskopiya, No. 6, 27–35 (1965).

A. V. Makarov, R. A. Savray, E. S. Gorkunov, et al., “Effect of hardening friction treatment on the special features of magnetic and eddy-current control of annealed structural steel subjected to cyclic loading,” Defektoskopiya, No. 7, 75–92 (2008).

E. S. Gorkunov, V. M. Somova, A. V. Makarov, et al., “Magnetic and electromagnetic methods of estimation of wear resistance of steel articles,” Defektoskopiya, No. 6, 33–39 (1995).

A. V. Makarov, E. S. Gorkunov, L. Kh. Kogan, et al., “Eddycurrent and coercivity-metering control of abrasive wear resistance of steel ShKh15 subjected to laser and volume heat treatment,” Defektoskopiya, No. 10, 3–16 (2006).

L. G. Korshunov, A. V. Makarov, and A. L. Osintseva, “A study of wear resistance and structural transformations in abrasive wear of laser-hardened steel U8,” Trenie Iznos, 9(1), 52–59 (1988).

E. S. Gorkunov, A. V. Makarov, L. G. Korshunov, et al., “A method for determining the wear resistance of steels and alloys, RF Patent 2069343, MKI G 01 N 3/58,” Byull. Izobr. Polezn. Modeli, No. 32 (1996).

I. I. Mal’ko, N. N. Zatsepin, and V. E. Maksimkov, “Eddy-current control of the depth of a layer hardened after laser treatment on articles from steels Kh12M, 45, U10, and ShKh15,” Defektoskopiya, No. 1, 95–96 (1989).

D. Schneider and B. Brenner, “Zerstörungsfreie Bestimmung der Einhärtungstiefe des lasergehärteten Stahls X20Cr13 mit Ultraschall-Oberflächenwellen,” Neue Hütte, 34(10), 374–378 (1989).

S. Kahrobaee and M. Kashefi, “Hardness profile plotting using multi-frequency multi-output electromagnetic sensor,” Nodestr. Test. Eval. Int., 44, 335–338 (2011).

A. V. Makarov, E. S. Gorkunov, I. Yu. Malygina, et al., “Eddycurrent control of the hardness, wear resistance and thickness of coatings obtained by the method of gas-powder laser deposition,” Defektoskopiya, No. 11, 68–78 (2009).

V. V. Dyakin and V. A. Sandovskii, The Theory and Design of Attached Eddy-Current Converters [in Russian], Nauka, Moscow (1981), 136 p.

A. V. Makarov, L. Kh. Kogan, E. S. Gorkunov, Yu. M. Kolobylin, “Eddy-current control of wear resistance of carburized chromium-nickel steel 20KhN3A,” Defektoskopiya, No. 2, 67–78 (2001).

A. V. Makarov, L. G. Korshunov, and A. L. Osintseva, “Effect of tempering and friction heating on the wear resistance of laser-hardened steel U8,” Trenie Iznos, 12(5), 870–878 (1991).

M. N. Mikheev and E. S. Gorkunov, Magnetic Methods of Structural Analysis and Nondestructive Check [in Russian], Nauka, Moscow (1993), 252 p.

E. S. Gorkunov, B. M. Lapidus, A. V. Zagainov, et al., “A study of differential magnetic permeability for checking the quality of surface hardening,” Defektoskopiya, No. 7, 7–13 (1988).

C. Zhang, N. Bowler and C. Lo, “Magnetic characterization of surface hardened steel,” J. Magn. Magn. Mater., 321, 3878–3887 (209).

E. S. Gorkunov, S. Yu. Mitropol’skaya, S. M. Zadvorkin, et al., “Effect of laser surface hardening on magnetic characteristics of carbon steel under loading conditions,” Defektoskopiya, No. 8, 58–66 (2008).

E. S. Gorkunov, S. Yu. Mitropol’skaya, A. L. Osintseva, and D. I. Vichuzhanin, “A study of strain and an evaluation of stresses in materials with hardened surface layers by magnetic methods,” Fiz. Mezomekhan., 12(2), 95–104 (2009).

E. S. Gorkunov, S. Yu. Mitropol’skaya, E. M. Groznaya, et al., “Effect of elastoplastic loading on magnetic properties of steel 20 hardened by gas carburizing,” Defektoskopiya, No. 4, 3–16 (2011).

S. V. Panin, “Laws of plastic deformation and fracture at the mesolevel of materials with coatings and surface hardening,” Fiz. Mezomekhan., Special Issue, 7(1), 109–1123 (2004).

M. A. Shtremel, The Strength of Alloys, Part II, Deformation [in Russian], MISiS, Moscow (1997), 527 p.

V. M. Dekhtyar, “About the coercivity of a two-layer cylinder,” Zh. Eksp. Teor. Fiz., Issue 10, 2–7 (1946).

E. S. Gorkunov, S. M. Zadvorkin, I. G. Emel’yanov, and S. Yu. Mitropol’skaya, “Laws of variation of magnetic characteristics of two-layer articles from carbon steels under tension,” Fiz. Met. Metalloved., 103(6), 657–666 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 42 – 48, March, 2013.

Rights and permissions

About this article

Cite this article

Mitropol’skaya, S.Y. Certification of hardened surface layers by magnetic and electromagnetic methods. Met Sci Heat Treat 55, 157–162 (2013). https://doi.org/10.1007/s11041-013-9598-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9598-4