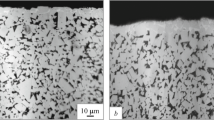

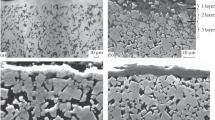

Hard alloy VK10KS is strengthened to a depth of 15 – 20 μm by subjecting the surface to pulse plasma jets formed by electric explosion of a titanium foil together with a weighed portion of SiC. Such a treatment produces a surface layer consisting of TiC,W2C, (W, Ti)C1 – x carbides and WSi2 silicide. The surface hardness is increased to 26,000 MPa and the wear resistance is enhanced.

Similar content being viewed by others

References

A. N. Ivanov, V. S. Khmelevskaya, I. A. Antoshina, et al., “Structural changes in hard alloy VK8 under ion irradiation,” Perspekt. Mater., No. 1, 89 – 92 (2003).

V. A. Tarbikov, G. E. Remnin, and P. V. Kuznetsov, “Modification of hard-alloy plates based on tungsten carbides by a powerful ion beam,” Fiz. Khim. Obrab. Mater., No. 3, 11 – 17 (2004).

Yu. N. Tyurin, S. N. Kul’kov, O. V. Kolisnichenko, et al., “Impulse plasma modification of the surface of articles from alloy WC + 20% Co,” Fiz. Inzh. Poverkhn., 7(3), 262 – 267 (2009).

E. A. Budovskikh, S. V. Karpiy, and V. E. Gromov, “Formation of surface layers of metals and alloys by electric explosion alloying,” Izv. Ross. Akad, Nauk, Ser. Fiz., 73(9), 1324 – 1327 (2009).

A. Ya. Bagautdinov, E. A. Budovskikh, Yu. F. Ivanov, et al., Physical Foundations of Electric Explosion Alloying of Metals and Alloys [in Russian], Izd. SibGIUm Novokuznetsk (2007), 301 p.

S. G. Andryushin, A. V. Kasatkin, V. M. Kuchumova, et al., “Mechanical characteristics of adhesion joints of buffer thinfilm coatings with hard-alloy substrates,” Materialovedenie, No. 6, 43 – 51 (2003).

T. N. Oskolkova and E. A. Budovskikh, “A method for surface hardening of tungsten-cobalt hard-alloy tools, RF Patent No. 2413792, MPK C23C 14/32, C23C 14/48, 2009134016/02,” Appl. 10.09.2009; Publ. 10.03.2011, Byull. Izobr. Polezn. Modeli, No. 7 (2011).

G. V. Samsonov and I. M. Vinitskii, Refractory Compounds [in Russian], Metallurgiya, Moscow (1976), 560 p.

I. N. Chaporova and K. S. Chernyavskii, Structure of Sintered Hard Alloys [in Russian], Metallurgiya, Moscow (1975), 248 p.

L. Manlang, H. Xiaoying, D. Shitian, et al., “Diffraction-contrast study of microstructure and deformation process of WC – Co cemented carbide,” Int. Refr. Hard. Met., No. 3, 129 – 132 (1983).

B. J. Johannesson and R.Warren, “Subcritical crack growth and plastic deformation in the fracture of hard metals,” Mater. Sci. Eng. A, 105/106, 353 – 361 (1988).

D. J. Rowcliffe, V. Jayaram, M. K. Hibbs, and R. Sinclair, “Compressive deformation and fracture in WC materials,” Mater. Sci. Eng. A, 105/106, 299 – 303 (1988).

A. F. Lisovskii, “Sintered hard alloys: self-organization of defects and concept of structure formation,” Sverkhtverd. Mater., No. 6, 48 – 53 (2001).

A. F. Lisovskii, “Increasing the operating capacity of hard-alloy mining tools,” Sverkhtverd. Mater., No. 5, 15 – 20 (2000).

M. G. Loshak, Strength and Endurance of Hard Alloys [in Russian], Naukova Dumka, Kiev (1984), 328 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 39 – 42, February, 2013.

Rights and permissions

About this article

Cite this article

Oskolkova, T.N., Budovskikh, E.A. Electric explosion alloying of the surface of hard alloy vk10ks with titanium and silicon carbide. Met Sci Heat Treat 55, 96–99 (2013). https://doi.org/10.1007/s11041-013-9587-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9587-7