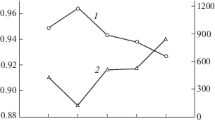

The properties of sintered permanent magnets produced by the traditional process (TP) and by a low-oxygen process (LOP) with the use of (Nd, Dy) – Fe – B rapidly hardened plate alloys are compared. Optimization of the LOP gives highly coercive magnets with world-level properties, i.e., B r ≥ 12.7 kGs, H c ≥ 25.0 kOe, and (BH )max ≥ 38 MGs ∙ Oe.

Similar content being viewed by others

References

S. Hirosawa, “Recent developments and future perspectives of Nd – Fe – B permanent magnets for automotive applications,” BM News, 3(35), 135 – 154 (2006).

M. Sagawa, S. Fujimura, H. Yamamoto, et al., “Permanent magnet materials based on the rare earth-iron-boron tetragonal compounds,” IEEE Trans. Magn., 20(5), 1584 – 1569 (1984).

J. F. Herbst, “R2Fe14B materials: intrinsic properties and technological aspects,” Rev. Modern. Phys., 63(4), 819 – 898 (1991).

Y. Hirose, H. Hasegawa, S. Sasaki, and M. Sagawa, “Microstructure of strip cast alloys for high performance NdFeB magnets,” in: Proc. 15th Int. Workshop on REPM and Their Applications, Dresden, Germany (1998), pp. 77 – 86.

S. Sasaki, J. Fidler, and M. Sagawa, “High performance sintered Nd – Fe – B magnets made by new RIP from SC alloys,” in: Proc. 16th Int. Workshop on REPM and Their Applications, Sendai, Japan (2000), pp. 109 – 118.

A. G. Popov, N. V. Kudrevatykh, V. P. Vyatkin, et al., “Experience of fabrication of high-quality magnets from alloys of type Nd – Fe – B produced by the method of strip casting,” Perspekt. Mater., Special Issue 6, Dec., 348 – 353 (2008).

A. G. Popov, N. V. Kudrevatykh, V. P. Vyatkin, et al., “Fabrication of high-energy permanent magnets from plate Nd – Fe – B alloys,” Fiz. Met. Metalloved., 109(3), 257 – 266 (2010).

W. F. Li, T. Ohkubo, K. Hono, amd M. Sagawa, “The origin of coercivity decrease in fine grained Nd – Fe – B sintered magnets,” J. Magn. Magn. Mater., 321, 1100 – 1105 (2009).

GOST 5639–82, Steels and Alloys. Methods for Revealing and Determining the Grain Size [in Russian], Izd. Standartov, Moscow (1983), 21 p.

The work has been performed with support of the Program for Fundamental Research of the Ural Branch of the Russian Academy of Sciences (Project No. 12-M-23-2066).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 21 – 26, February, 2013.

Rights and permissions

About this article

Cite this article

Popov, A.G., Vasilenko, D.Y., Puzanova, T.Z. et al. Highly coercive sintered magnets from (Nd, Dy) – Fe – B alloys fabricated by the method of strip casting. Met Sci Heat Treat 55, 78–82 (2013). https://doi.org/10.1007/s11041-013-9583-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9583-y