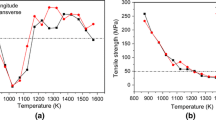

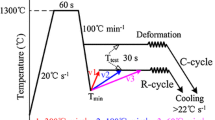

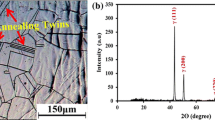

Hot ductility of steel 08Kh18N10T is studied on heating and cooling in the range 600 – 1050°C with a deformation rate of 3.3 × 10-3 sec-1. Reasons are detected and explained for the occurrence of steel ductility peaks in heating ad cooling branches of dependences on test temperature. Recommendations are given for a forming regime.

Similar content being viewed by others

References

A. P. Surovtsev and V. E. Sukhanov, “Features of deformability of corrosion-resistant chromium-nickel steels of the austenitic class,” Metalloved. Term. Obrab. Met., No. 6, 30 – 33 (1990).

B. I. Medovar, Welding of Chromium-Nickel Austenitic Steels [in Russian], Mashgiz, Moscow (1966).

L. M. Kaputkina, S. V. Dobatkin, and T. K. Zhdanovich, “Softening mechanism with hot working of austenitic stainless steel,” Izv. Akad. Nauk SSSR, Metally, No. 4, 122 – 129 (1985).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 8 – 9, June, 2011.

Rights and permissions

About this article

Cite this article

Viktorov, N.A. Hot ductility of steel 08Kh18N10T. Met Sci Heat Treat 53, 263–264 (2011). https://doi.org/10.1007/s11041-011-9379-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-011-9379-x