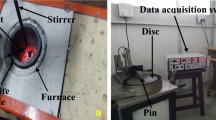

The wear resistance of aluminum has been improved with zirconia material. The method consists in compacting aluminum powder and the compacted piece immersed several times in a colloidal zirconia solution until a constant weight was reached. The solution penetrated the piece and infiltrated the preform. A wear test was carried out in a pin-on-disc machine. By measuring the weight loss, it was shown that the composite had significant improvement in wear resistance compared to pure aluminum.

Similar content being viewed by others

References

I. M. Hutchings, S. Wilson, and A. T. Alpas, “Wear of aluminum- based composites,” Comprehensive Compos. Mater., 3, 501 – 519 (2000).

M. K. Surappa, “Aluminum matrix composites: challenges and opportunities,” Sadhana, 28(1 – 2), 319 – 334 (2003).

Y. B. Liu, S. C. Lim, L. Lu, and M. O. Lai “Recent development in the fabrication of metal matrix-particulate composites using powder metallurgy techniques,” J. Mater. Sci., 29(8), 1999 – 2007 (1994).

D. Casellas, A. Beltran, J. M. Prado, A. Larson, and A. Romero, “Microstructural effects on the dry wear resistance of powder metallurgy Al – Si alloys,” Wear, 257(7 – 8), 730 – 739 (2004).

G. Abouelmagd, “Hot deformation and wear resistance of P/M aluminum metal matrix composites,” J. Mater. Proces. Technol., 155 – 156, 1395 – 1401 (2004).

L. Geng, S. Ochiai, H. X. Peng, et al., “Fabrication of nanocrystalline ZrO2 particle reinforced aluminum alloy composite by squeeze casting route,” Scr. Mater., 38(4), 551 – 557 (1998).

S. K. Pradhan, A. Datta, A. Chatterjee, et al., “Synthesis of aluminum matrix composites containing nanocrystalline oxide phase,” Bull. Mater. Sci. (India), 17(6), 849 – 853 (1994).

S. K. Shee, S. K. Pradhan, and M. De, “Effect of thermal stress on the microstructures of aluminum metal matrix composites,” Mater. Chem. Phys., 52(3), 228 – 234 (1998).

J. M. Ruiz Prieto, L. García Cambronero, J. M. Torralba, and F. Velasco, Manual de Pulvimetalurgia, Edited by: Cátedra Höganäs de Pulvimetalurgia de la Universidad Carlos III de Madrid (1999).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 22 – 24, August, 2010.

Rights and permissions

About this article

Cite this article

Fuentes-Ramirez, R., Perez-Gonzalez, A. & Castaño Meneses, V.M. Improved wear resistance of an aluminum – zirconia composite. Met Sci Heat Treat 52, 368–370 (2010). https://doi.org/10.1007/s11041-010-9284-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-010-9284-8